A large mine bolted steel structure cylinder

A steel structure and bolt technology, which is applied in the field of large-scale mining bolts to connect steel structure cylinders, can solve the problems of high labor intensity of welding workers, easy cracks, and long installation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

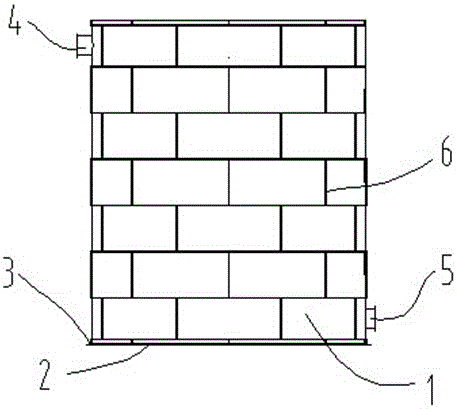

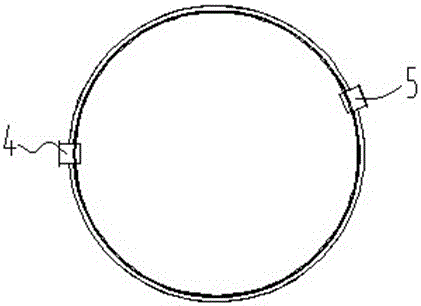

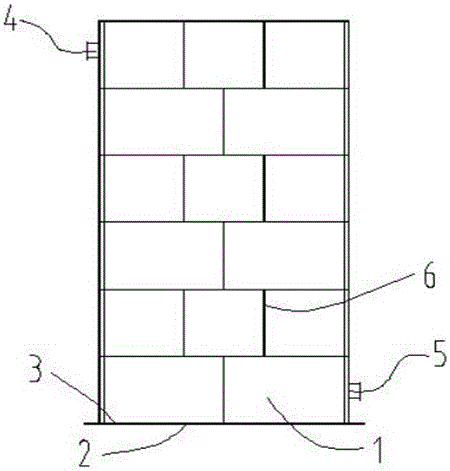

[0013] Refer to the attached figure 1 , Embodiment 1, a three-dimensional structure of a circular cylinder, a large-scale mining bolted steel structure cylinder, including a wall plate 1, a bottom plate 2, a pre-embedded plate 3, a ore feed port 4, a ore discharge port 5, and a filler 6 , Bolt 7, which is characterized in that: the cylinder wall 1 is composed of multi-section cylinder sections, the cylinder sections are coaxially arranged and connected by bolts 7; the cylinder section is composed of multiple sections of steel plates with flange surfaces, and the cylinder section Filling material 6 is added on the flange surface between the two parts, and bolts 7 are used to connect the wall plate 1 to form the cylinder; The connection is fixed; the wall plate 1 of the cylinder body is provided with a ore feeding port 4 and a ore discharge port 5; a layer of pre-embedded plate 3 is arranged under the bottom plate 2, and the bottom plate 2 and the embedded plate 3 are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com