Device and method for pneumatically removing sands from casting and recovering sands

A casting and air-cooling technology, applied in the direction of cleaning/processing machinery, casting molding equipment, manufacturing tools, etc. cost, saving processing time and avoiding energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

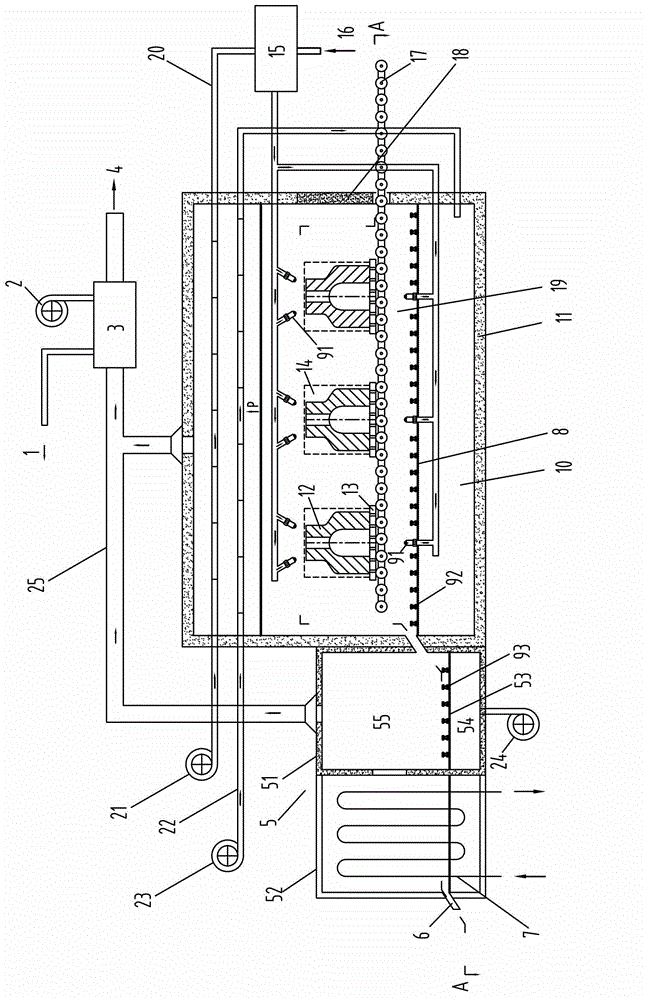

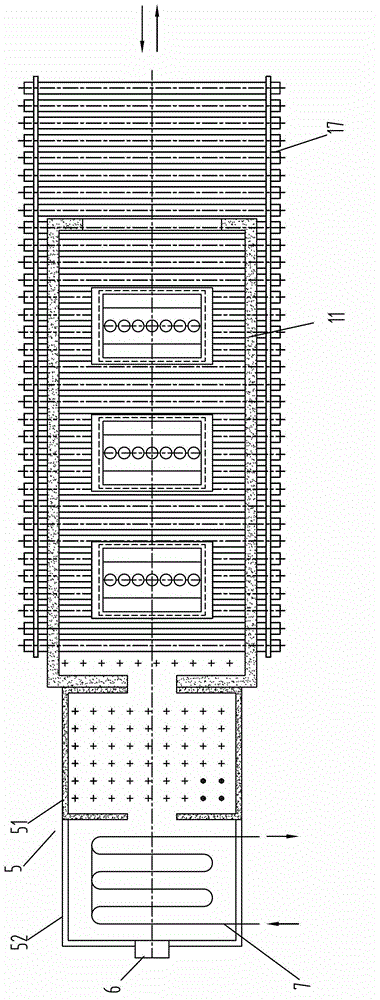

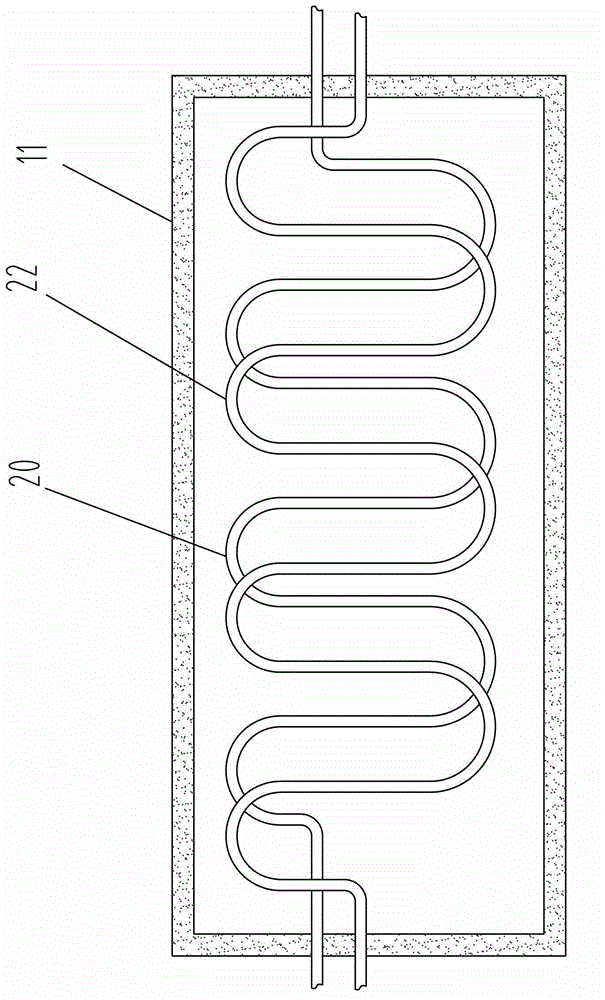

[0038] Such as figure 1 , figure 2 , image 3 As shown, the present invention provides a device for pneumatic desanding and sand regeneration of castings, including three main parts of furnace body 11, cooling classifier 5 and waste heat recovery device, wherein:

[0039] Described body of furnace 11, the inner wall of body of furnace 11 is provided with insulating and high-temperature-resistant material, and body of furnace 11 is provided with closed clapboard 8, and described body of furnace 11 is divided into the buoyancy pressure chamber 10 of lower layer and the fluidized bed of upper layer. Room 19, the fluidized bed room 19 is provided with a roller table 17 (or bracket), and the side of the fluidized bed room 19 is provided with a working room door 18, which is used for the sand mold to enter the fluidized bed room 19 or after sand removal The castings 12 are moved out of the fluidized bed chamber 19, and the upper and lower sides of the roller table 17 are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com