Fully automatic melting argon-rich mixed gas shielded welding single-sided welding and double-sided forming bottoming method

A single-sided welding double-sided, mixed gas technology, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc. Eliminate over-dependence, reduce impact probability, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

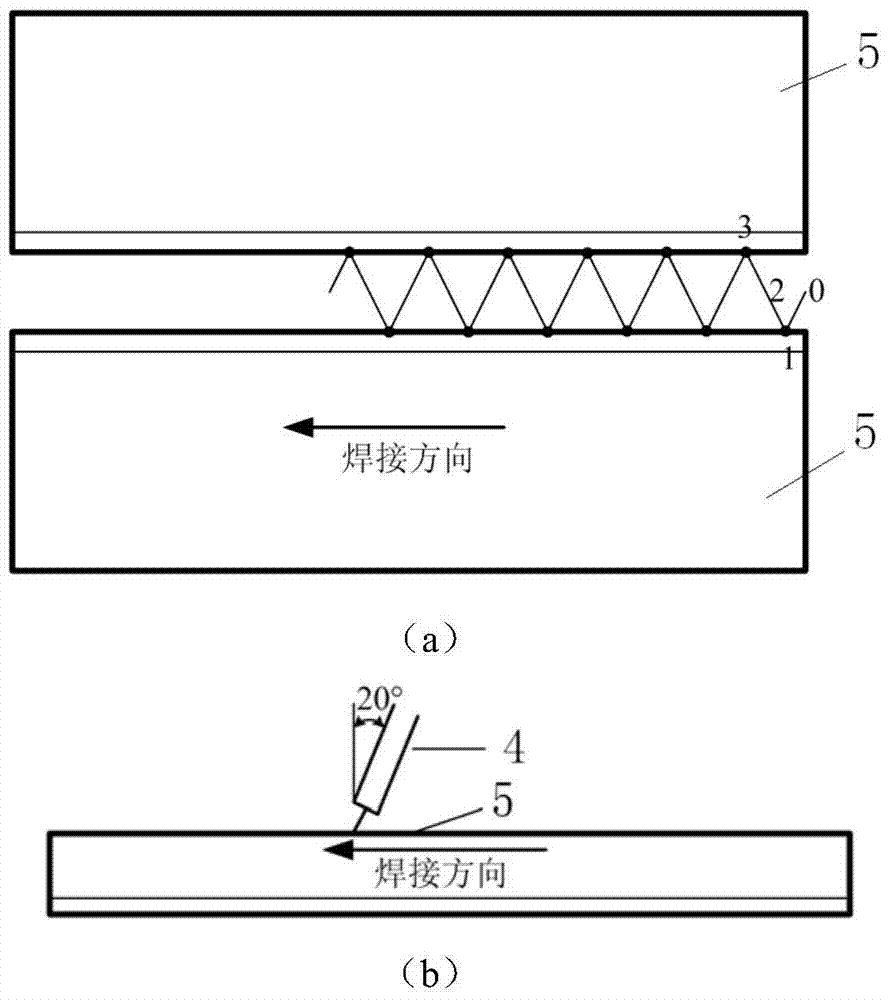

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

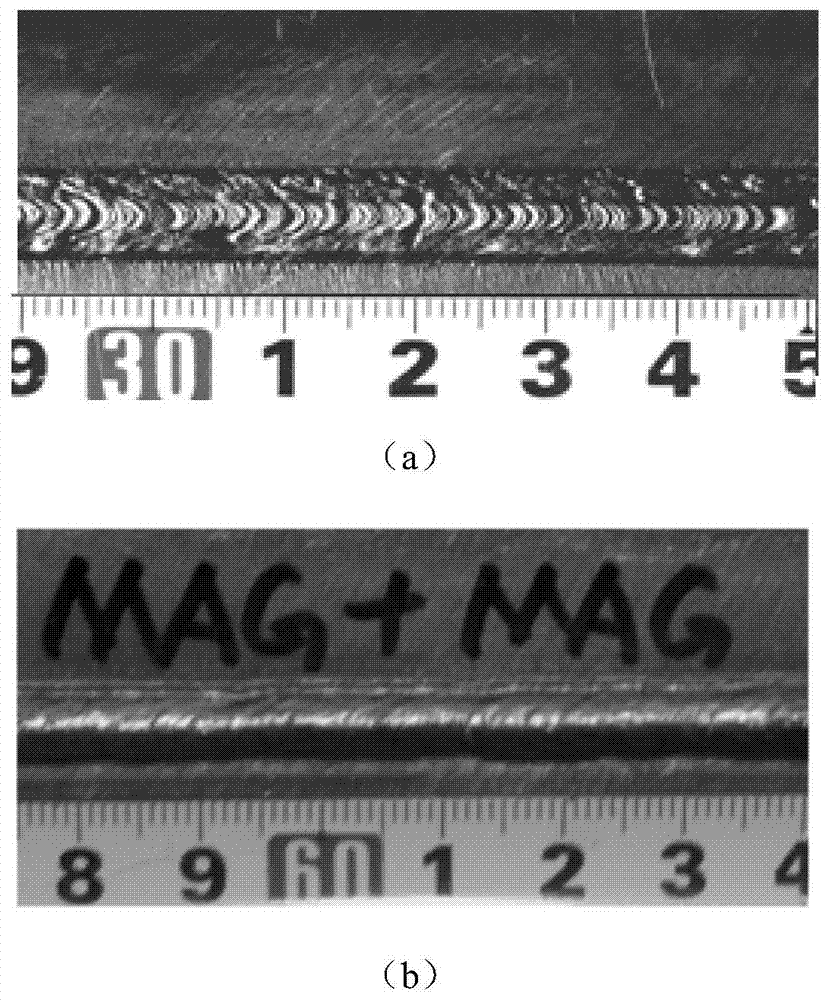

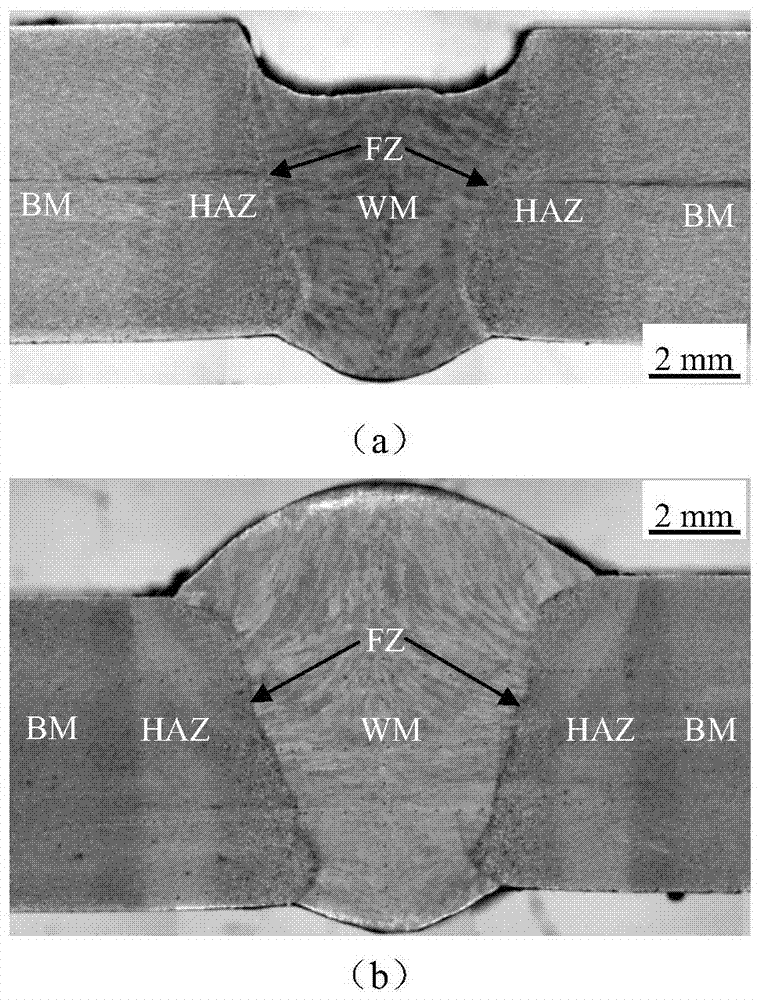

[0030] In the context of the sharp increase in labor costs, in order to realize the automatic priming of fully automatic MAG, it is easy to solve the difficulty of "burn-through" (at this time, in the contradiction between burn-through and incomplete penetration, burn-through is the main aspect of the contradiction) , the present invention is based on the core characteristics of argon-rich-filament and spray transition commonly used in molten argon-rich mixed gas shielded welding (MAG). double impact on the molten pool) instead of the excessive volume of the molten pool caused by heating, in order to obtain the comprehensive effect of penetration and anti-burn-through in the bottom pass, it has established a focus on reducing and dispersing the "arc plasma flow" The technical solution of the double impact force of the force and the high-speed droplet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com