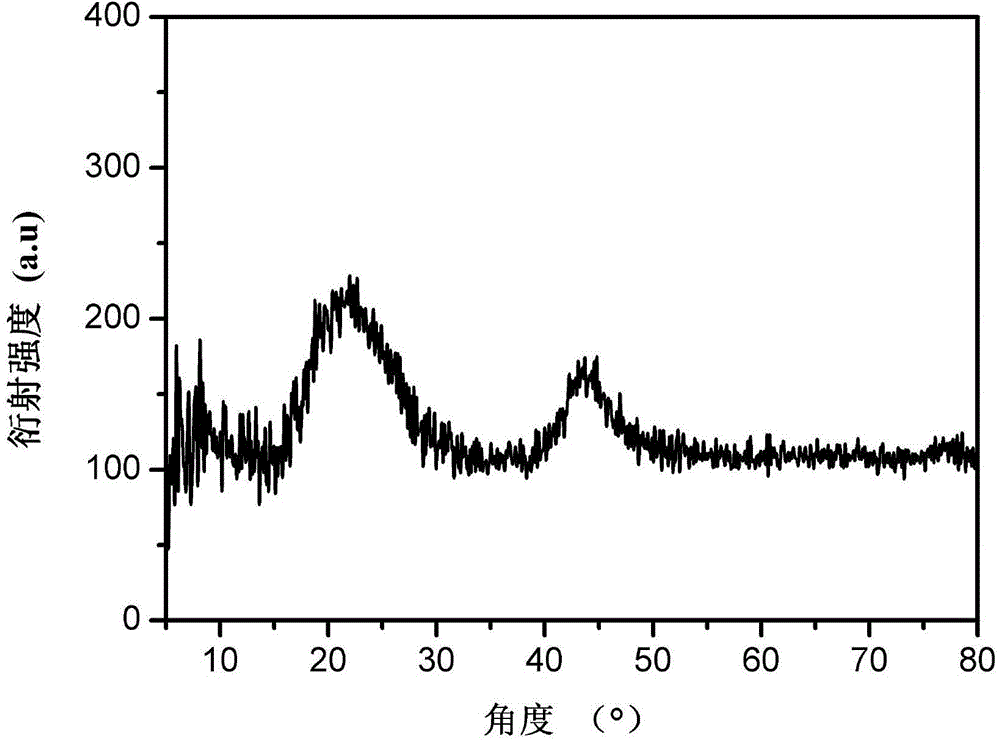

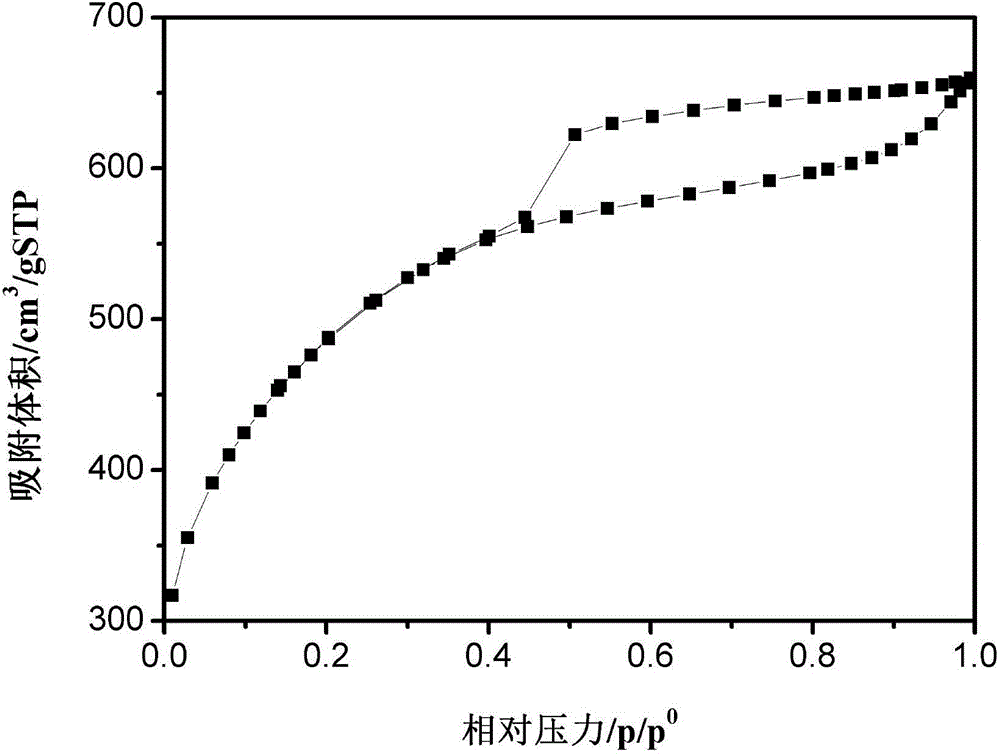

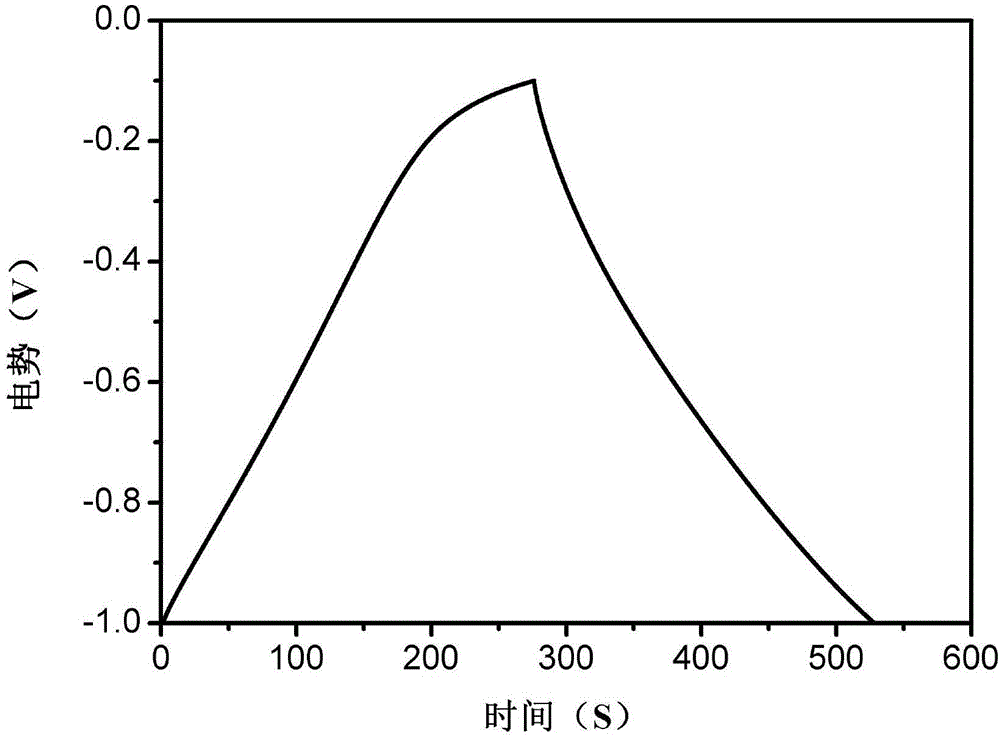

Method for preparing porous nano carbon materials with biomass serving as carbon source

A nano-carbon material and biomass technology, which is applied in the field of preparing porous nano-carbon materials, can solve the problems of complex process, high production cost, and high price, and achieve the effect of cheap and easy-to-obtain materials, low production cost, and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Specific embodiment one: a kind of method for preparing porous nano-carbon material with biomass as carbon source of the present embodiment, specifically operates according to the following steps:

[0024] 1. First weigh the loofah, then calcinate it to black fiber shape under the condition of inert gas atmosphere and temperature of 200-600°C, the calcining time is 30-60min, and carry out pre-carbonization;

[0025] 2. Add an activator to the pre-carbonized loofah in step 1, and stir for 4-10 hours at a temperature of 30-50°C and a stirring speed of 50-300r / min to obtain a precursor; Under the condition of 50-100°C, dry for 6-12 hours to obtain an intermediate product; wherein, the mass ratio of loofah and activator is 1:1-5;

[0026] 3. Heat-treat the intermediate product obtained in step 2 to obtain the product, wherein the heat-treatment conditions are: under the condition of a heating rate of 1-20°C / min, the temperature is raised to 600-1400°C, and the inert gas flo...

specific Embodiment approach 2

[0029] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the pre-carbonization temperature in step 1 is any temperature within the range of 200-600°C. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the pre-carbonization temperature in Step 1 is 300-500°C. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com