Preparation method of polyester for manufacturing high-modulus low-shrinkage industrial yarn

A low-shrinkage, industrial yarn technology, applied in the field of polyester manufacturing, can solve the problems that polyester cannot meet the application requirements of high-modulus and low-shrinkage industrial yarns, and achieve the production rate and performance improvement, good purity, and high viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0017] Terephthalic acid and ethylene glycol undergo esterification reaction at a temperature of 250-290 ° C, and the molar ratio of raw materials is terephthalic acid: ethylene glycol = 1: (1.1-1.5). The intermediate bishydroxyethyl terephthalate is produced, reacted until the esterification rate is at least 92%, and the generated water is removed during the reaction.

[0018] In the presence of a mixed catalyst system, the intermediate bishydroxyethyl terephthalate undergoes polycondensation reaction under negative pressure (2000-100Pa) to obtain polyester products. The polycondensation reaction temperature is 270-300°C and the reaction time is 2 ~3 hours.

[0019] After the selected mixed catalyst enters the preparation area, add ethylene glycol (hereinafter referred to as: EG) to dilute the catalyst concentration to 2wt%.

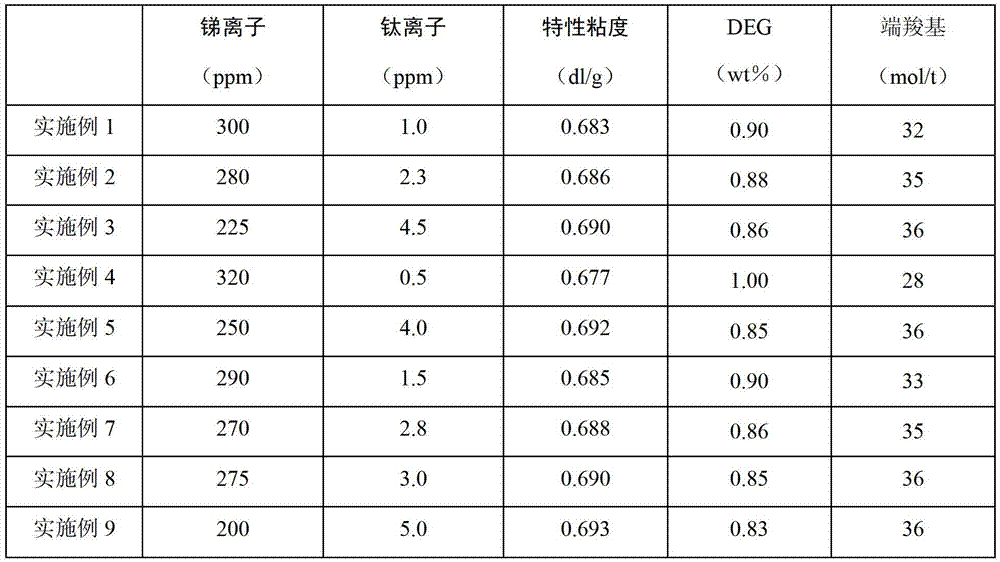

[0020] The mixed catalyst system control used in the polycondensation reaction of each embodiment and the main quality indicators of polyester product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com