Test method for on-line circulation of delayed coking cycle oil

A delayed coking and test method technology, applied in the field of delayed coking test equipment, can solve the problems of low test efficiency and high labor intensity, and achieve the effects of reducing labor intensity, reducing workload and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

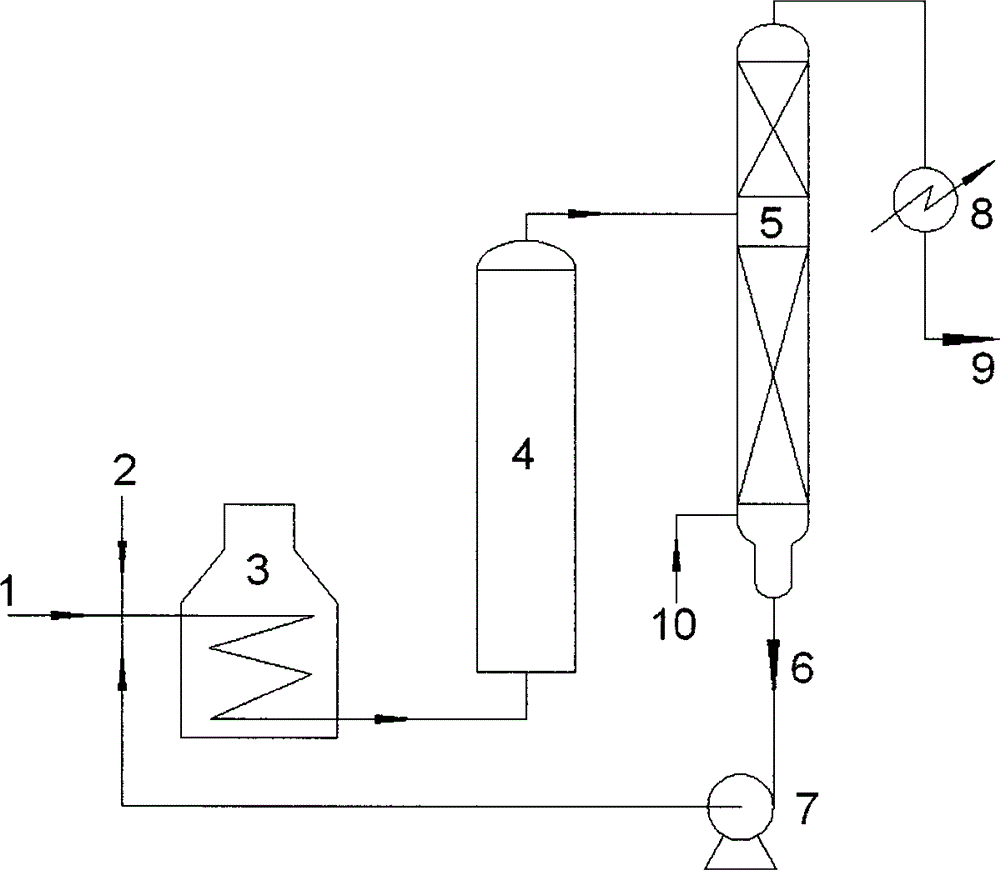

Method used

Image

Examples

Embodiment 1

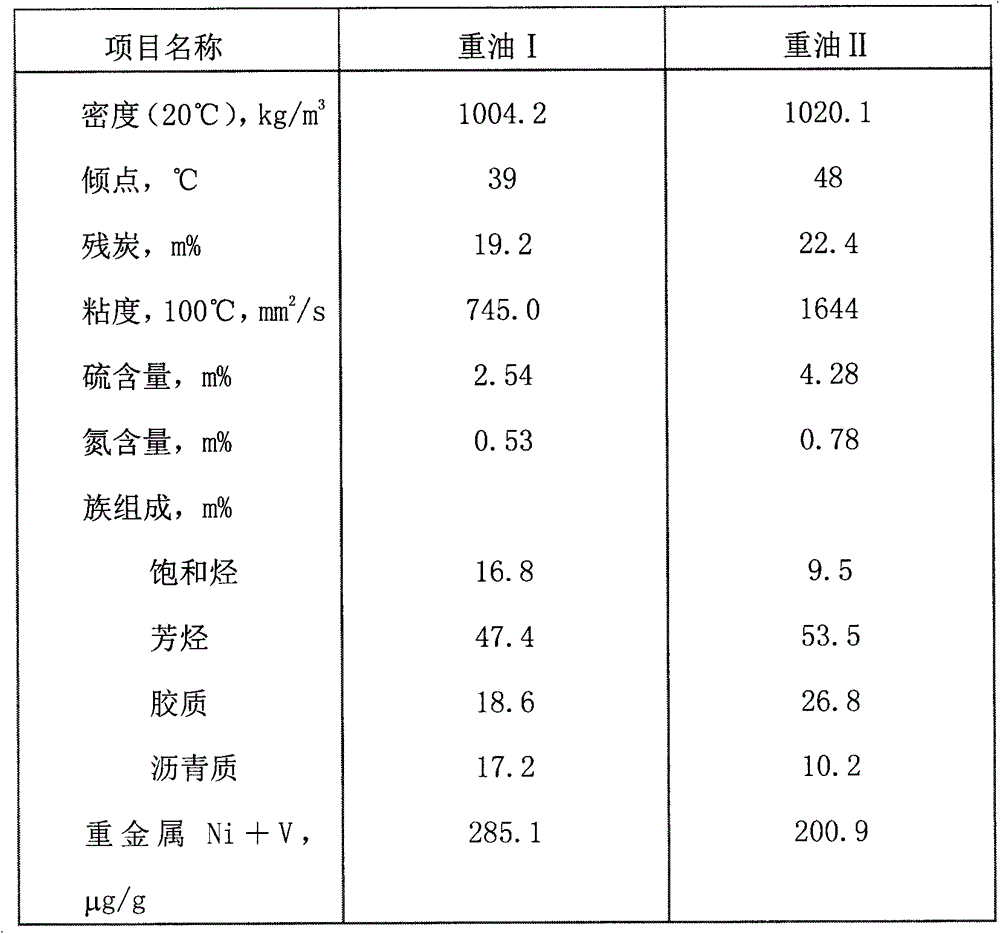

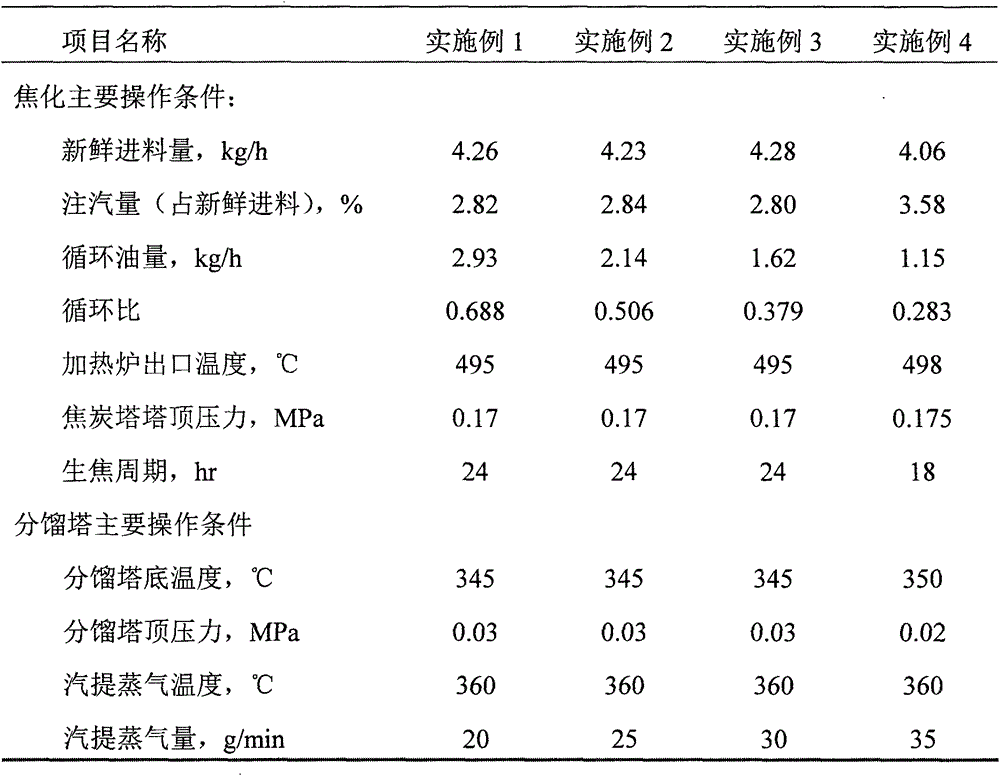

[0034] Process description: The feed is 4.26kg / h of 120°C heavy oil I (properties are listed in Table 1) through pump pressurization with 2.93kg / h of 270°C circulating oil and 2g / min of 345°C water from the bottom of the fractionation tower After the steam is mixed, it enters the heating furnace for heating. The material temperature at the outlet of the heating furnace is controlled to be 495°C, and then enters the coke tower for cracking and condensation reactions under a pressure of 0.17MPa. The generated coke remains in the coke tower, and the high-temperature oil and gas coming out of the top of the coke tower enters the fractionation tower for separation. 20g / min of 360°C water vapor is blown into the lower part. After fractionation, the mixed oil gas and non-condensable gas (rich gas) of gasoline, diesel and coker wax oil come out from the top of the fractionation tower, and then are condensed, cooled, recovered and metered; The inlet to the furnace is mixed with fresh ...

Embodiment 2

[0039] The process description is the same as in Example 1, and the process conditions when the circulation ratio is 0.506 are shown in Table 2; the separation effect is shown in Table 3.

Embodiment 3

[0041] Process description is the same as embodiment 1, and the process conditions when the recycle ratio is 0.379 are shown in Table 2; Separation

[0042] The effect is shown in Table 3.

[0043] It can be seen from Table 3 that when the other conditions are basically the same, the properties of coker gas oil and cycle oil change greatly after changing the cycle ratio operation. That is, as the circulation ratio decreases, the cut point increases, the density of coker wax oil and cycle oil increases, the carbon residue and asphaltenes increase, and the distillation range becomes heavier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com