Lubricating oil composition for antiskid differential

A technology of lubricating oil composition and anti-slip differential, which is applied in the field of lubricating oil composition and anti-slip differential lubricating oil composition, which can solve the problem that the friction characteristics cannot meet the lubrication requirements of vehicle anti-slip differential and cannot guarantee the anti-slip differential Problems such as the normal operation of the device and the impact on the performance of the vehicle, to achieve good economic and social benefits, low production costs, and excellent friction characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

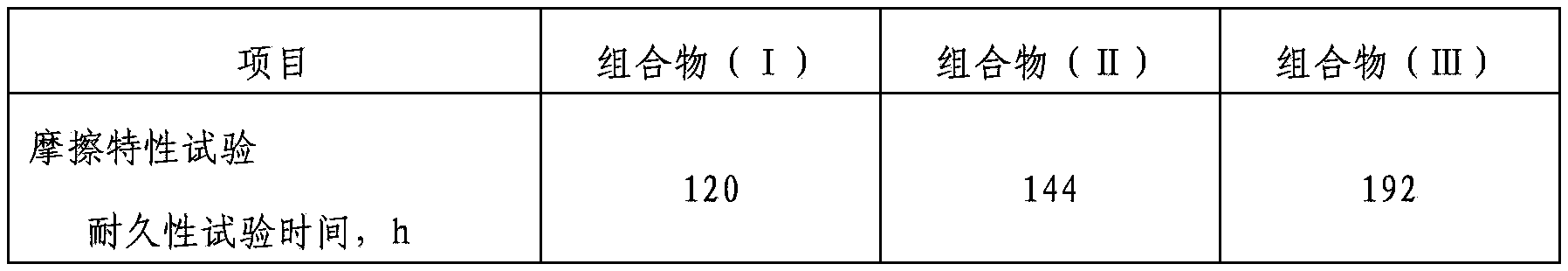

Embodiment 1

[0018] Lubricating oil composition (I), it comprises: 4.155wt% solvent deep refined base oil HVIS150BS, 78.945wt% solvent deep refined base oil HVIS500 (component A); 5.0wt% polymethacrylate (component B); 0.1wt% polya-olefin (component C); 3.8wt% RHY4208A vehicle gear oil compound additive (component D); 3.0wt% polyisobutenyl succinimide, 3.0wt% C20 -24 Calcium Alkylbenzene Sulfonate (Component E); 1.0 wt% Octadecyl Phosphite, 1.0 wt% Borated Glycerol Oleate (Component F). Lubricating oil composition (II) except component (E) 3.0wt% polyisobutenyl succinimide, 3.0wt% C20-24 calcium alkylbenzene sulfonate is replaced by 3.0wt% borated polyisobutenyl Except for succinimide and 3.0wt% calcium alkylbenzenesulfonate of C20-24 instead, the rest are the same as composition (I). Lubricating oil composition (Ⅲ) except component (E) 3.0wt% polyisobutenyl succinimide, 3.0wt% C20-24 calcium alkylbenzene sulfonate and 3.0wt% boron phosphated polyisobutene Except for succinimide, 3.0wt% ...

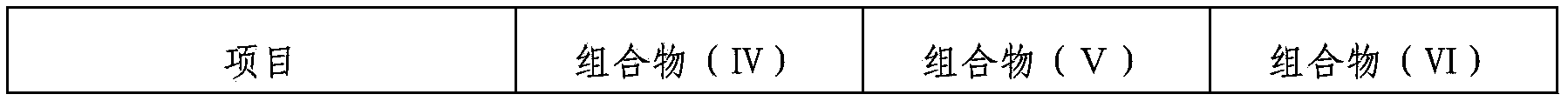

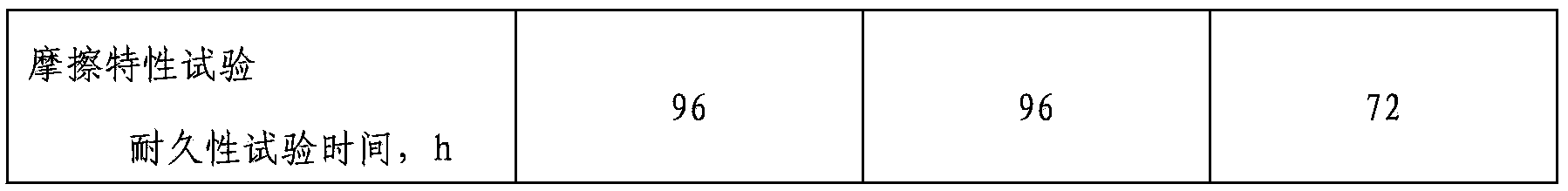

Embodiment 2

[0023] Lubricating oil composition (Ⅳ), it comprises: 85.3wt% Daqing hydroisomerization dewaxed base oil No. 5 oil (component A); 8.0wt% polymethacrylate (component B); 1.5wt% % polyalphaolefin (component C); 3.8wt% of RHY4208A vehicle gear oil compound additive (component D); 0.5wt% of boron phosphated polyisobutenyl succinimide, 0.5wt% of C20-24 Calcium alkylbenzene sulfonate (component E); 0.2 wt% dodecyl phosphonate, 0.2 wt% borated pentaerythritol oleate (component F). Lubricating oil composition (Ⅴ) except component (E) 0.5wt% boron phosphate polyisobutenyl succinimide, 0.5wt% C20-24 calcium alkylbenzene sulfonate is replaced by 0.5wt% boron phosphorus Except for polyisobutenyl succinimide and 0.5wt% C10-14 sulfurized calcium alkylphenate instead, the rest are the same as composition (IV). The lubricating oil composition (Ⅵ) except component (E) 0.5wt% boron phosphated polyisobutenyl succinimide, 0.5wt% C20-24 calcium alkylbenzene sulfonate is replaced by 0.5wt% boron p...

Embodiment 3

[0029] Additive composition (VII), which includes: 55.12wt% poly-alkene synthetic oil PAO4, 13.78wt% diester synthetic oil (component A); 20.0wt% polymethacrylate (component B ); 0.1wt% polya-olefin (component C); 5.5wt% RHY4208A vehicle gear oil compound additive (component D); 3.5wt% boron phosphated polyisobutenyl succinimide, 0.5wt% C20-24 calcium alkylbenzenesulfonate (component E); 1.0 wt% dodecyl phosphite, 0.5 wt% borated glycerol oleate (component F). The evaluation results of composition (VII) are listed in Table 3.

[0030] Table 3 Composition (Ⅶ) evaluation results

[0031]

[0032] The experimental results show that the lubricating oil composition (VII) not only passed the four gear racks of L-42, L-37, L-33, and L-60-1, but also reached the specification index of GB13895-92 (API GL—5) , and has excellent durability of friction characteristics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com