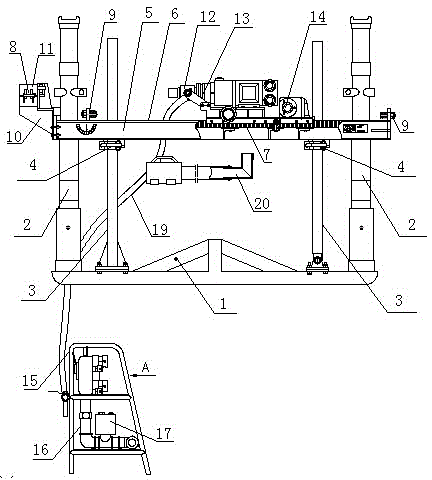

Pneumatic post drill

A technology for drilling rigs and supporting columns, which is applied to drilling equipment, earth-moving drilling, drilling equipment and methods, etc., can solve the problems of inconvenient portability and use, time-consuming and labor-intensive, complex structure, etc., and achieves low labor intensity, high efficiency, Small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

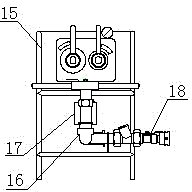

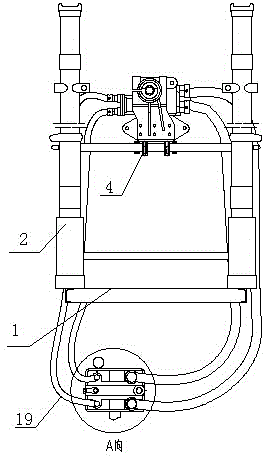

Method used

Image

Examples

Embodiment 1

[0030] In Example 1, the working air pressure is 0.40Mpa, the rated torque is 250 N m, the rated speed is 280 r / min, the maximum output power is 7.3 kW, the maximum load torque is 405 N m, and the stall torque is 440 N m. Torque 430 N m, load air consumption 8 m3 / min, no-load speed 600 r / min, 1 / 2 no-load speed 300 r / min, torque 230 N m at 1 / 2 no-load speed, propulsion The air consumption of the motor is 4.5 m3 / min, the noise sound pressure level is 106 dB(A), the sound power level is 116 dB(A), the propulsion force is 14 kN, the extraction force is 18 kN, the drilling diameter is Φ76~φ110 mm, and the guide rail length is 2720 mm , guide rail propulsion stroke 1240 mm, no-load propulsion speed 5000 mm / min, return speed 4000 mm / min, maximum working height 1490 mm, minimum working height 510 mm.

Embodiment 2

[0031]In Example 2, the working air pressure is 0.50Mpa, the rated torque is 300 N m, the rated speed is 290 r / min, the maximum output power is 9 kW, the maximum load torque is 455 N m, the stall torque is 490 N m, and the starting Torque 480 N m, load air consumption 10 m3 / min, no-load speed 630 r / min, 1 / 2 no-load speed 315 r / min, torque 275 N m at 1 / 2 no-load speed, propulsion motor Air consumption 5.0m3 / min, noise sound pressure level 108dB(A), sound power level 118dB(A), propulsion force 14 kN, pulling force 18 kN, drilling diameter Φ76~φ110 mm, guide rail length 2720 mm, guide rail propulsion The stroke is 1240 mm, the no-load propulsion speed is 5000 mm / min, the return speed is 4000 mm / min, the maximum working height is 1490 mm, and the minimum working height is 510 mm.

Embodiment 3

[0032] In Example 3, the working air pressure is 0.63Mpa, the rated torque is 330N m, the rated speed is 300 r / min, the maximum output power is 10kW, the maximum load torque is 515 N m, the stall torque is 550N m, and the starting torque is 540 N m, load air consumption 12m3 / min, no-load speed 680 r / min, 1 / 2 no-load speed 340 r / min, torque at 1 / 2 no-load speed 295 N m, propulsion motor air consumption 5.8 m3 / min, noise sound pressure level 110dB(A), sound power level 120dB(A), propulsion force 14 kN, pulling force 18 kN, drilling diameter Φ76~φ110 mm, guide rail length 2720 mm, guide rail propulsion stroke 1240 mm , no-load propulsion speed 5000 mm / min, return speed 4000 mm / min, maximum working height 1490 mm, minimum working height 510 mm.

[0033] From the above examples, it can be seen that this pneumatic column drilling rig has large torque, high speed, high work efficiency, low noise, simple structure, easy operation, convenient maintenance, low labor intensity for worker...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com