Safe and high pressure type magnetic heating reactor

A magnetic heating, high-pressure technology, used in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., can solve problems such as lack of safety, and achieve high work efficiency, reliable work, and operation methods. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with specific embodiment, further illustrate the present invention.

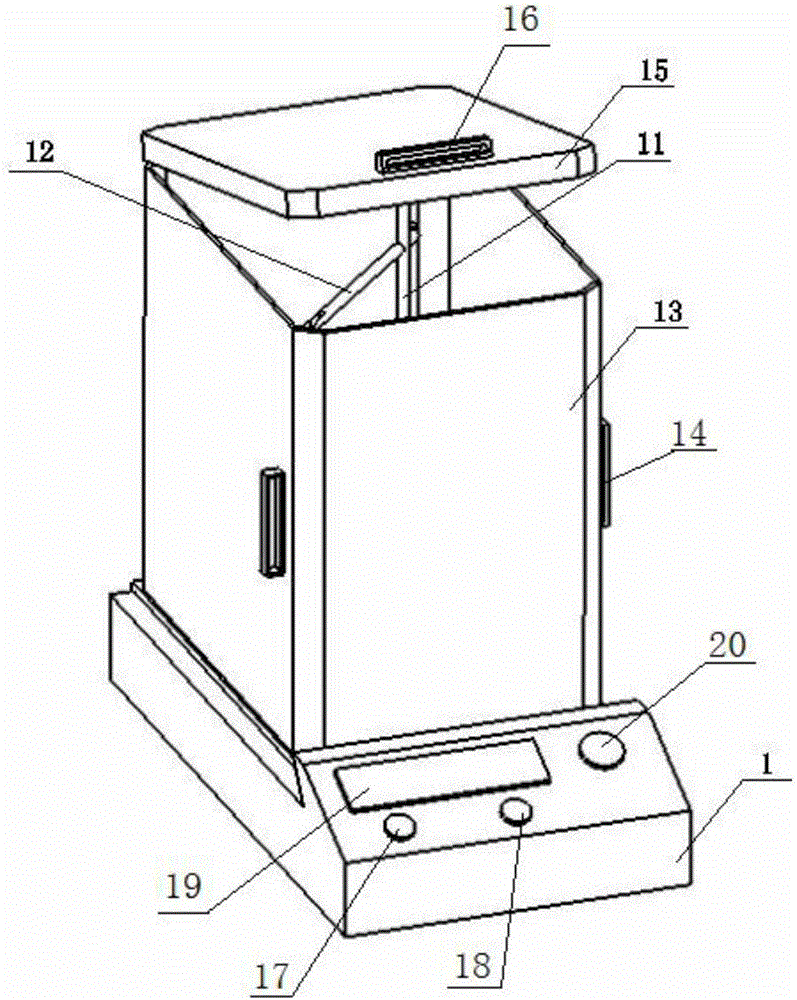

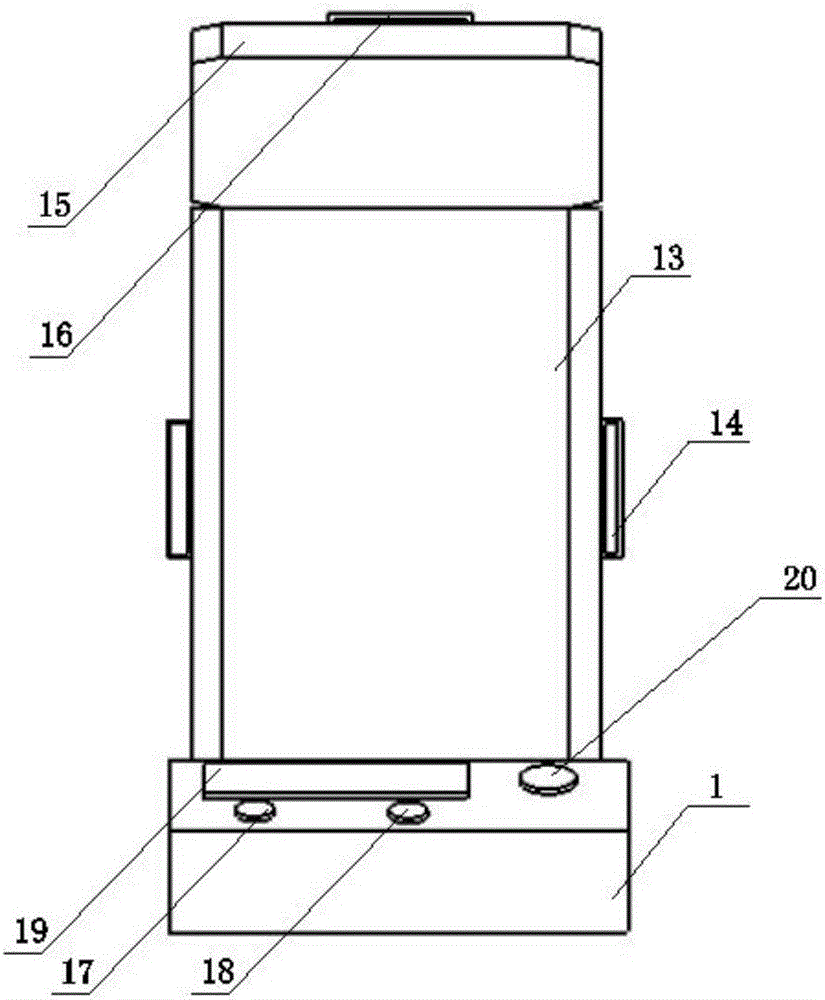

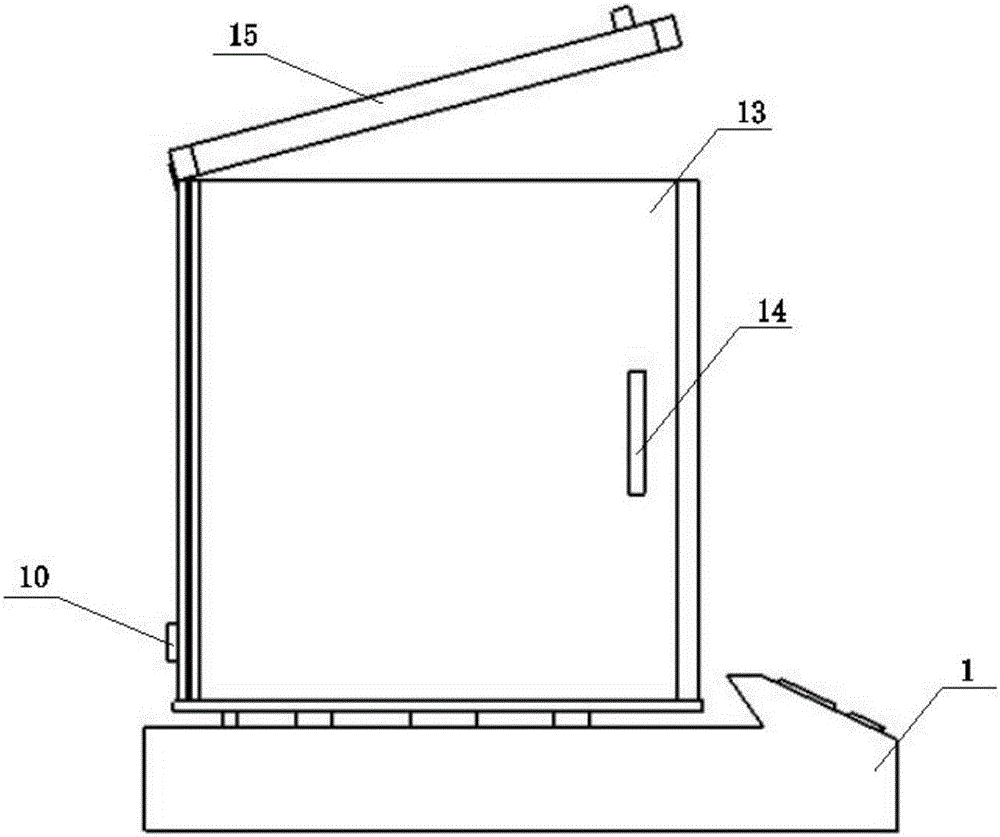

[0029] Such as Figure 1 to Figure 17 As shown, a safe high-pressure magnetic heating reactor, the main components are base 1, bottom plate 2, pad 3, magnet 4, disk 5, temperature sensor 6, pressure sensor 7, controller 8, container 9, electromagnetic Valve 10, support rod 11, reaction rod 12, outer shell 13, handle 14, upper cover 15, handle 16, temperature setting key 17, pressure setting key 18, display screen 19, switch 20, clip 21.

[0030] The safety high-pressure magnetic heating reactor includes a base area, a container area and an upper cover area. The base area is composed of base 1, bottom plate 2, spacer 3, magnet 4, disc 5, temperature setting key 17, pressure setting key 18, display screen 19, switch 20, base 1 is located at the bottom of the whole device and serves as a support , The role of fixtures. The front part of the base 1 has an operation panel, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com