Piston unit and hydrostatic radial piston machine

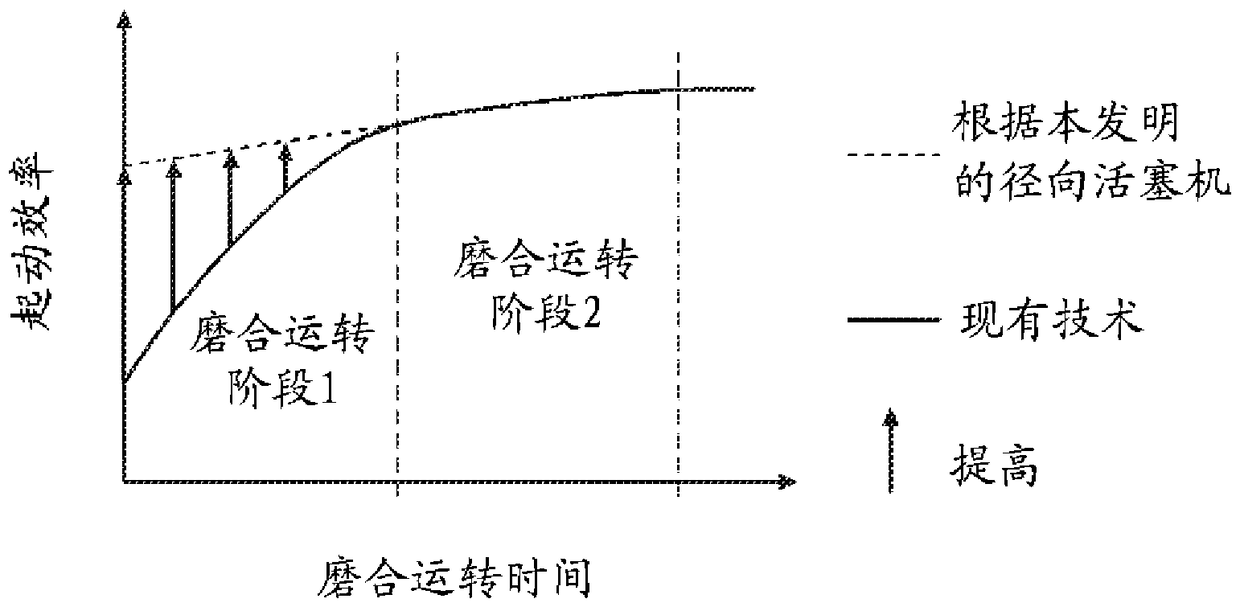

A technology of piston and hydraulic machine, applied in the field of radial piston machine and piston unit, can solve the problems of reducing starting torque, reducing efficiency, not small friction, etc., and achieving the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

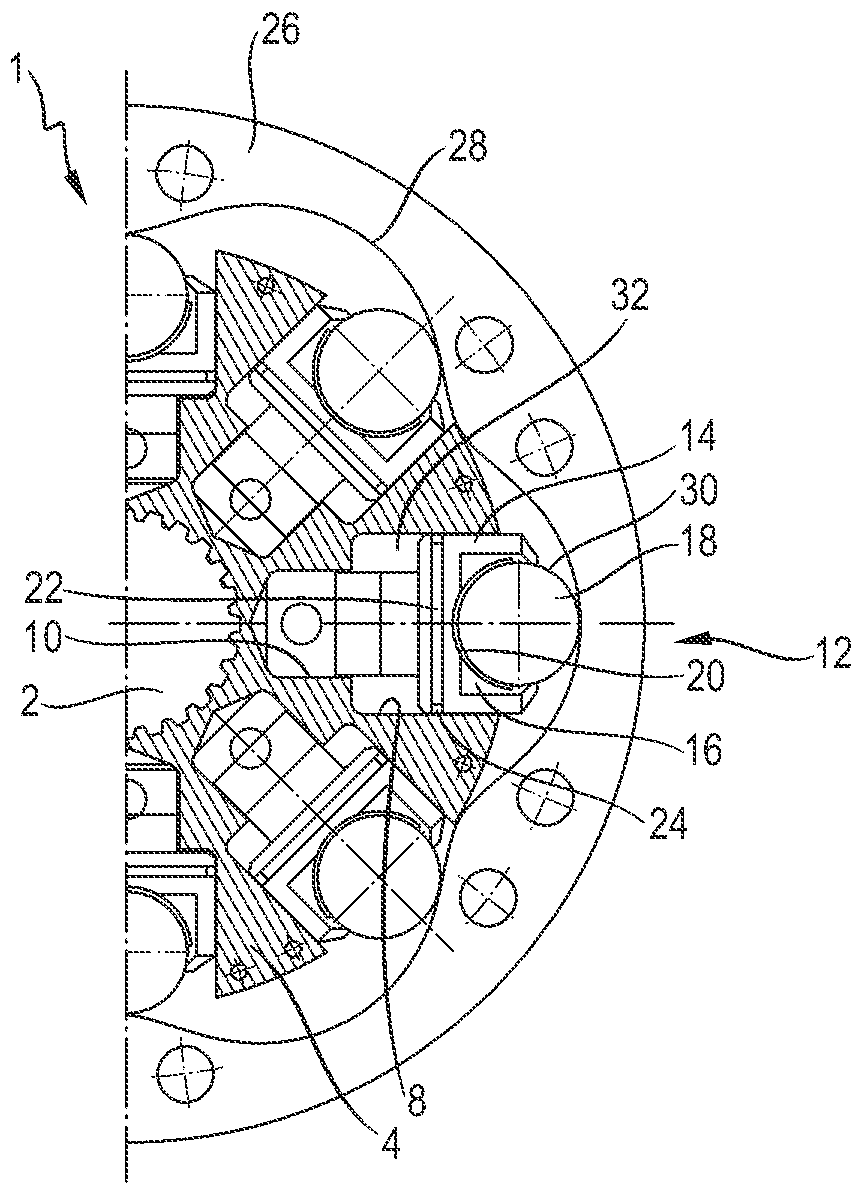

[0029] figure 1 An exemplary embodiment of the radial piston machine 1 described at the outset is shown in radial section. In the exemplary embodiment, the radial piston machine 1 is a hydrostatic radial piston motor with an external piston support.

[0030] The radial piston machine 1 has a centrally arranged shaft 2 . It is driven by a surrounding rotor 4 or a cylinder block in which a plurality of cylinders 6 are formed. In the illustrated embodiment, the radial piston machine 1 is provided with eight cylinders 6, in figure 1 Only the whole of three of them and the respective halves of the other two are shown in . The cylinders 6 are arranged radially or star-shaped around the axis 2 . Each cylinder 6 is formed by a main bore 8 and a guide bore 10 retracted radially step by step, in which a piston unit 12 is movably accommodated in the axial direction.

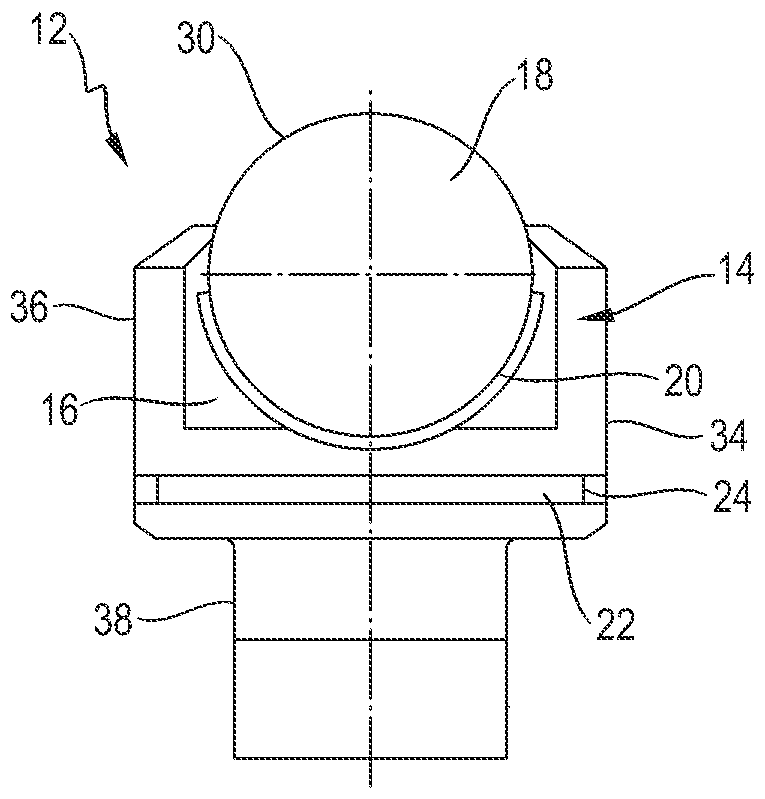

[0031] Each of the piston units 12 has a piston 14, which in the present embodiment is a multi-stage piston. At the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com