Magnetorheological damper having parallel normally-open holes and methods for calculating zero-field damping coefficient, on-field damping coefficient and damping force of magnetorheological damper

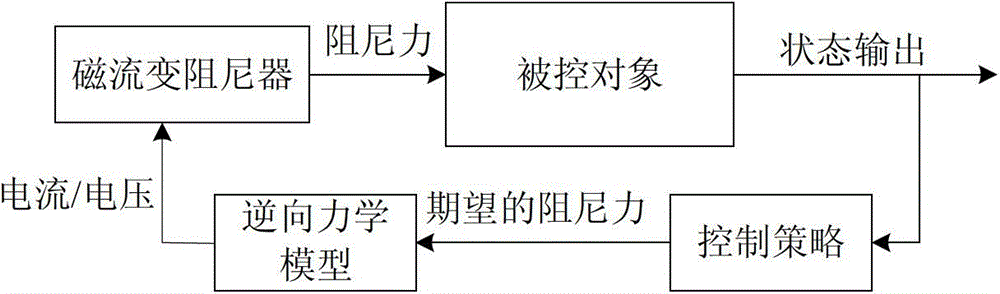

A magnetorheological damper, through-hole technology, used in shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of complex inverse mechanics model and control process, avoid flutter, improve Reliability, the effect of improving controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

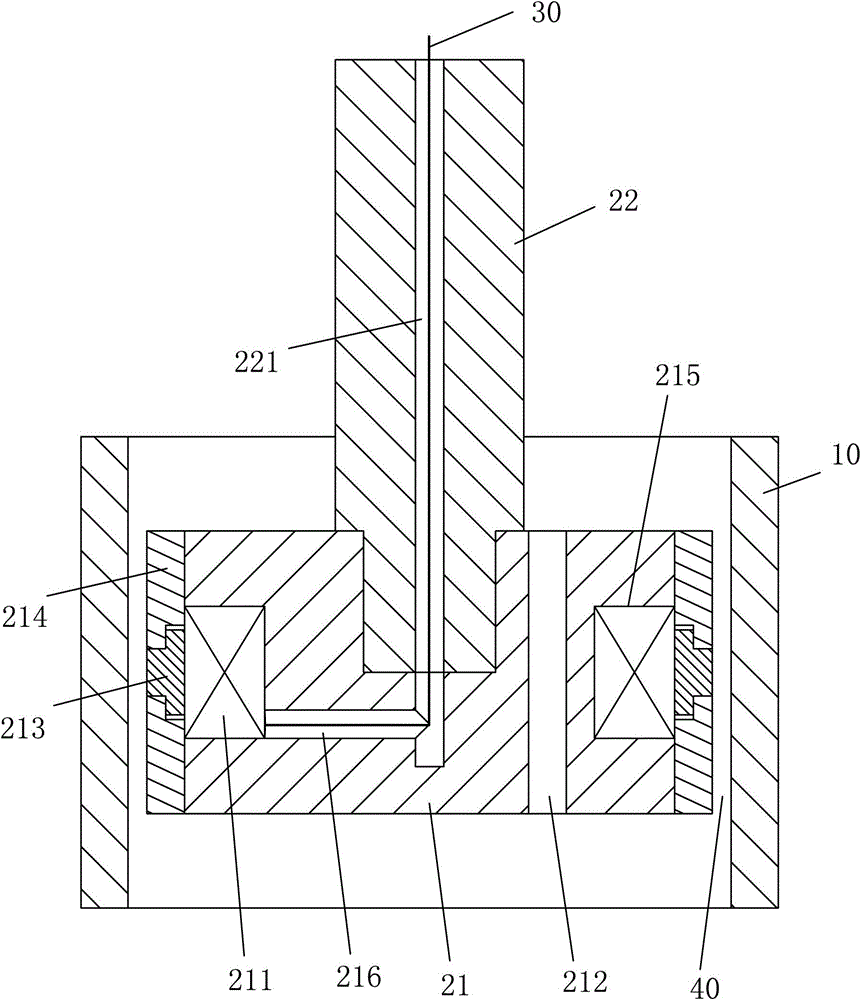

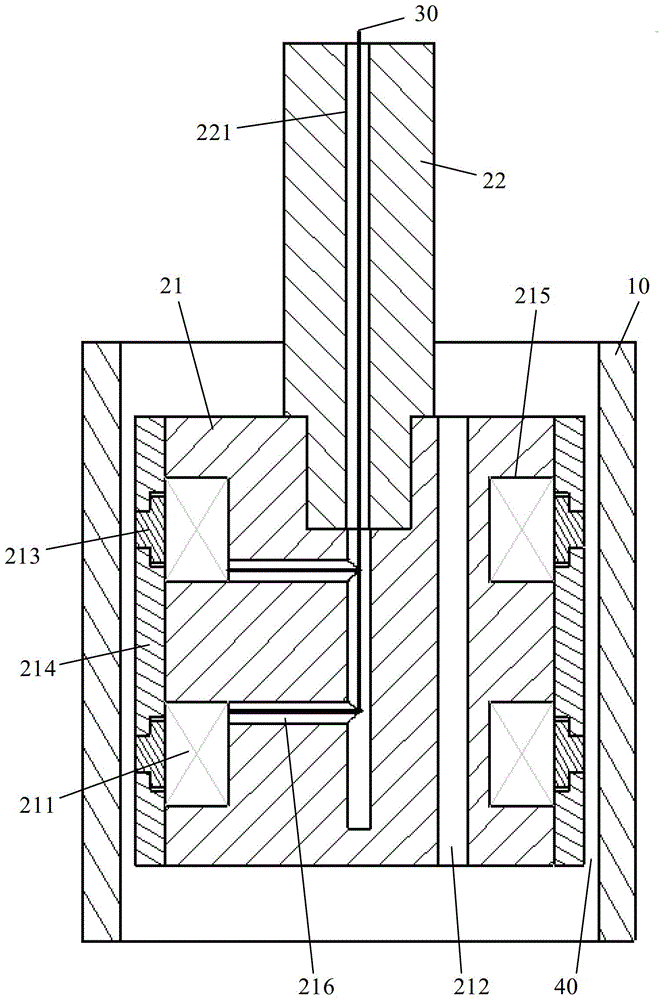

[0043] Such as Figure 2 to Figure 3 , The parallel normally-through hole magnetorheological damper of the present invention includes a hollow cylinder 10 in which a piston is slidably arranged, one end of the piston is fixedly connected to a piston rod 22, and the piston rod 22 extends from one end of the cylinder 10 Extending from the opening, for example, the piston rod 22 can be fixedly connected with the piston through screw connection or interference fit, and the piston slides in the cylinder 10 via the piston rod 22, wherein: the piston includes a cylinder Shaped iron core 21, the side wall (outer circular side wall) of the iron core 21 is recessed with at least one ring groove 215, each ring groove 215 is wound with an excitation coil 211, and the excitation coil 211 is connected to each other via a wire 30 Corresponding external power supply equipment (not shown in the figure) is connected, the excitation coil 211 is sheathed with a magnetic isolation protection ring 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com