Fitting and flat bar for textile processing machine

A technology of processing machine and cover bar, which is applied in the direction of textile and paper making, deburring device, fiber treatment, etc. It can solve the problems of expensive card clothing structure, expensive regrinding times, limited and other problems, and achieves easy assembly and disassembly, high fatigue The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

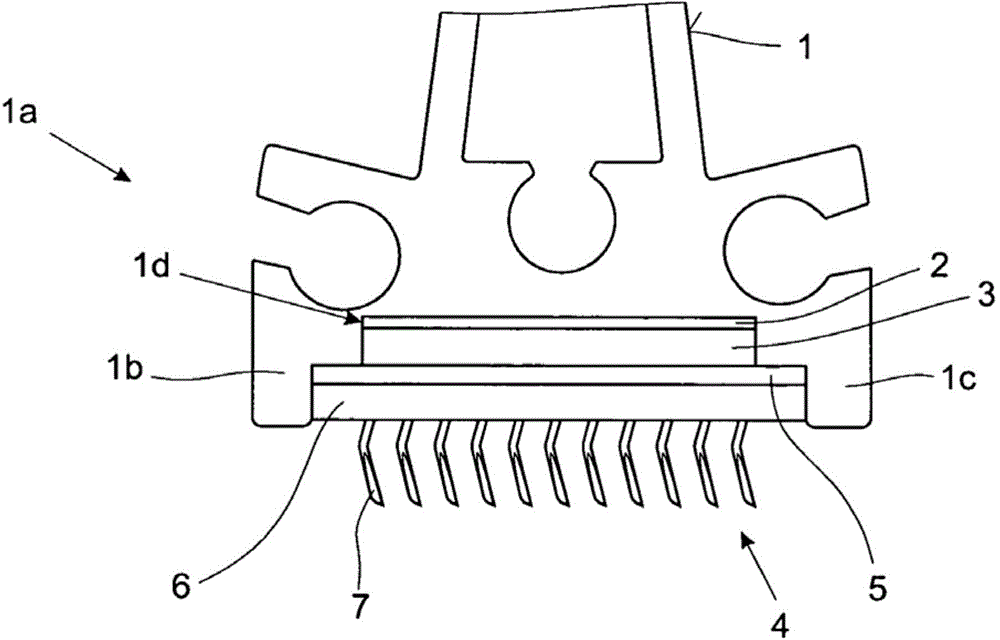

[0029] exist figure 1 A known flat rod 1 according to the prior art is shown in a side view. The flat bar 1 includes a flat head, not shown here, which, due to its geometry, is rigid enough to pass over the width of the cylinder of a carding machine (Karde) or carding machine (Krempel). Its zigzag wires create a constant carding gap. On the flat foot 1a, the two webs 1b, 1c arranged on both sides form a recess 1d which is suitable for receiving at least one flat clothing 4 . According to the example, this recess 1 d is embodied in two stages, so that the magnet 3 is firmly connected to the cover rod 1 via the fastening 2 . The fastening 2 can be embodied as an adhesive connection or another materially bonded connection, or also as a mechanical connection. The flat clothing 4 essentially comprises a carrier element 6 for receiving the small hooks 7 and a steel plate 5 which is connected to the carrier element 6 . The carrier element 6 usually consists of a textile or fabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com