Bending fully degradable magnesium alloy nerve guide and its preparation method

A nerve conduit and magnesium alloy technology are applied in the field of bendable and fully degradable magnesium alloy nerve conduits and their preparation. The invention can solve the problems of inflexibility of magnesium alloy nerve conduits, uncomfortable nerve repair, and the like, achieve the realization time and conduit degradation time, and inhibit bacteria. Excellent growth and biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The above-mentioned bendable fully degradable magnesium alloy nerve guide and its preparation method comprise the following steps:

[0044]Step 1, passing the initial magnesium alloy billet through an extrusion die to obtain a thick magnesium alloy wire;

[0045] Step 2, drawing the magnesium alloy thick wire obtained in step 1 through multiple passes to obtain a magnesium alloy wire of the final required size;

[0046] Step 3, performing stress relief annealing on the magnesium alloy wire obtained in step 2;

[0047] Step 4, polishing the magnesium alloy wire obtained in step 3;

[0048] Step 5, braiding the magnesium alloy wire obtained in step 4 to form a bendable fully degradable magnesium alloy nerve guide.

[0049] Further, in step 1, the outer diameter of the magnesium alloy initial billet is Φ20mm, and the length is 30mm; the extrusion temperature is 300-400°C; the size of the magnesium alloy thick wire is Φ1-3mm; Lubricant is sprayed between the extrusion di...

Embodiment 1

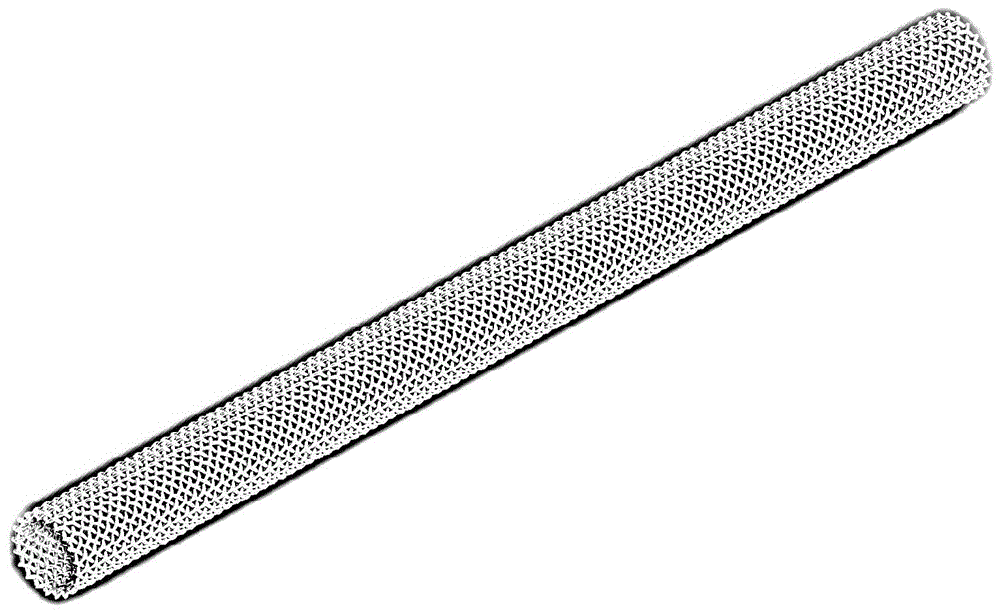

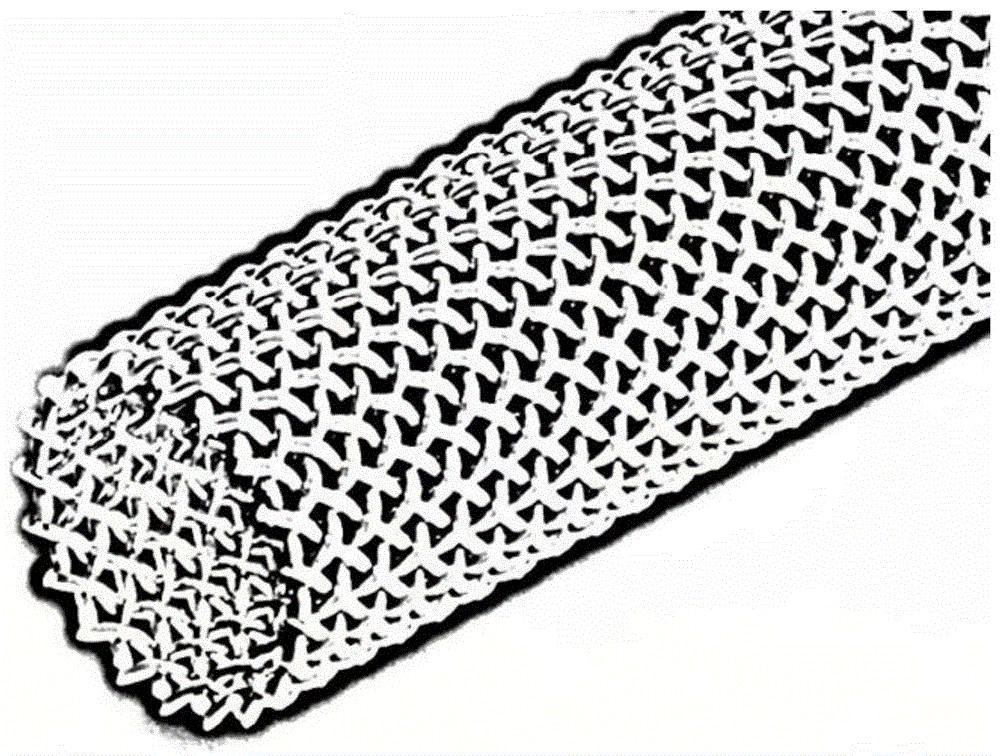

[0056] This embodiment relates to a flexible fully degradable magnesium alloy nerve guide for nerve defect repair, its structure is as follows figure 1 As shown, the length is 5mm, the outer diameter is 1mm, and the wall thickness is 0.10mm. The nerve guide is braided by filaments with a diameter of 0.05 mm, the distance between two adjacent rows of filaments in the same direction is 0.005 mm, and the braiding angle between each row of filaments and the tube axis is 45 degrees.

[0057] This embodiment relates to the aforementioned method for preparing a degradable magnesium alloy nerve guide for repairing nerve defects, and the shown method includes the following steps:

[0058] In step 1, the initial billet of Mg-Nd-Zn-Zr magnesium alloy with an outer diameter of 20mm and a length of 30mm is extruded at a temperature of 350°C to obtain Magnesium alloy thick wire;

[0059] Step 2, will Magnesium alloy thick wire with a diameter of 0.05mm is obtained after multi-pass draw...

Embodiment 2

[0064] This embodiment relates to a flexible fully degradable magnesium alloy nerve guide for nerve defect repair, its structure is as follows figure 1 As shown, the length is 100mm, the wall thickness is 0.40mm, and the outer diameter is 10mm. The nerve guide is braided by filaments with a diameter of 0.2 mm, the distance between two adjacent rows of filaments in the same direction is 0.05 mm, and the braiding angle between each row of filaments and the tube axis is 45 degrees.

[0065] This embodiment relates to the aforementioned method for preparing a degradable magnesium alloy nerve guide for repairing nerve defects, and the shown method includes the following steps:

[0066] Step 1, extruding the initial Mg-Zn-Zr magnesium alloy blank with an outer diameter of 20mm and a length of 30mm at a temperature of 300°C to obtain a thick magnesium alloy wire of Φ3mm;

[0067] Step 2, drawing the Φ3mm magnesium alloy thick wire through multiple passes to obtain a magnesium alloy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com