Environment-friendly granulation unit specially used for papermaking

A granulating unit and environmental protection technology, applied in coating and other directions, can solve the problems of high production cost, high labor intensity, and reduce production efficiency, and achieve the effect of improving the production workshop environment, reducing labor intensity and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

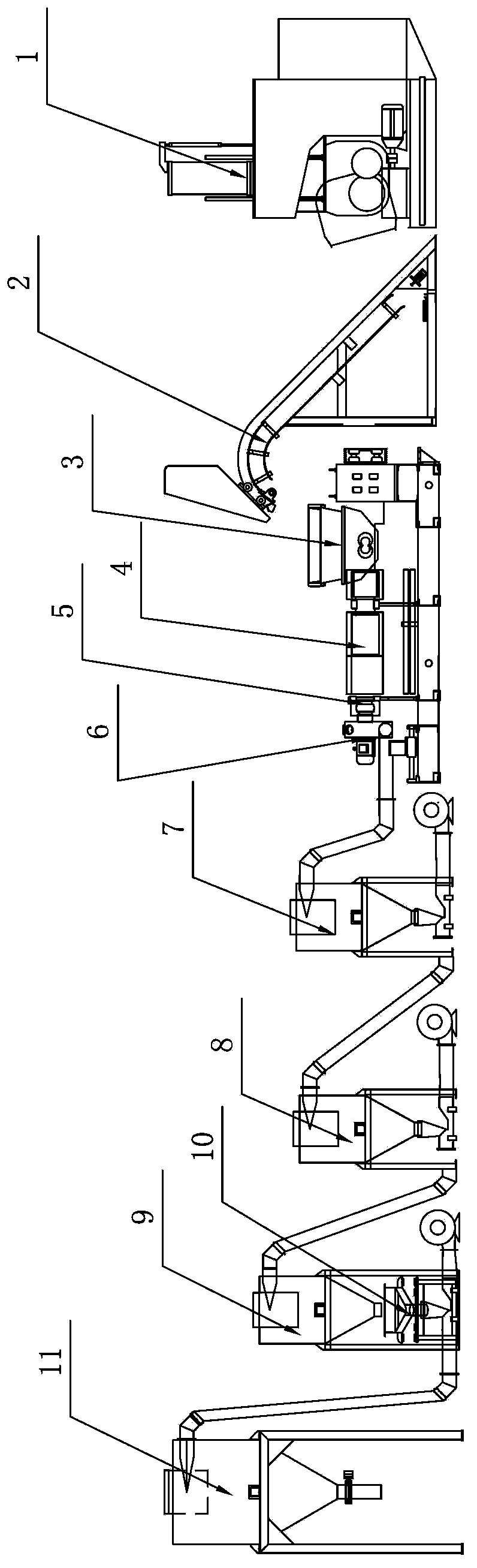

[0009] see figure 1 , the specific embodiment adopts the following technical solutions: it includes pressurized internal mixer 1, material bucket elevator 2, conical twin-screw feeder 3, single-screw extruder 4, hydraulic plate type automatic screen changer 5 , air-cooled mold surface eager cutting machine head 6, primary cyclone separator 7, secondary cyclone separator 8, tertiary cyclone separator 9, vibrating screen 1, finished product silo 11, the pressurized internal mixer 1 The left side of the material bucket elevator 2 is provided with a conical twin-screw feeder 3, and the left side of the conical twin-screw feeder 3 is provided with a single-screw extruder 4. The left end of the single-screw extruder 4 is provided with a hydraulic plate-type automatic screen changer 5, and the left end of the hydraulic plate-type automatic screen changer 5 is provided with an air-cooled mold surface hot-cutting head 6. The side is provided with a primary cyclone separator 7, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com