Double-runner and fluctuation-free screen exchanger

A non-fluctuation, screen changer technology, applied in the field of parts of plastic extruders, can solve the problems of poor sealing performance of screen changer, easy failure, loss of work stoppage, etc., to achieve easy operation, less loss of raw materials, and product quality. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

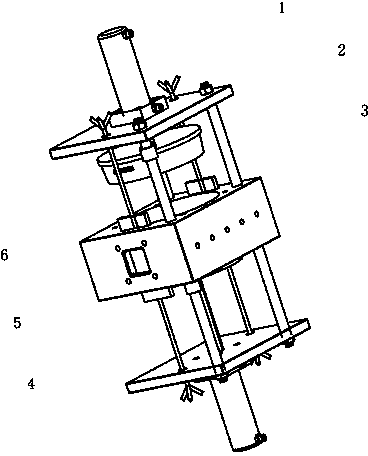

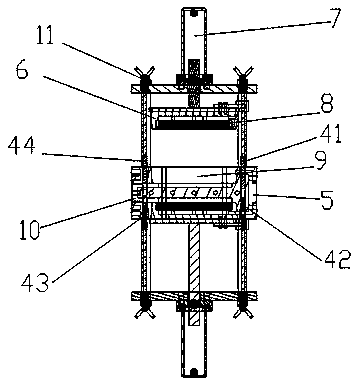

[0021] Such as figure 1 A double-channel wave-free screen changer shown includes a box body 3, a guide column 2, a wire mesh fixing base 6, an oil cylinder 7 and a fixing plate 1, and rectangular feeding ports 10 and Outlet 5, the upper and lower ends of the box are inwardly formed columnar chambers, and the upper and lower chambers are disconnected structures; the fixed plate 1 is connected with the box body 3 through guide columns 2, and the fixed plate 1 A wire mesh fixing base 6 is provided between the box body and the box body.

[0022] Two guide posts are provided at the feed port end of the box body, and one guide post is provided at the discharge port end of the box body, so as to facilitate taking out the screen mesh during the screen replacement process.

[0023] Two sets of guide sleeves are arranged on the guide column 2, and each set of guide sleeves is two and arranged diagonally.

[0024] The guide sleeve is connected with a wire mesh fixing base 6 through fix...

specific Embodiment 2

[0032] Such as Figure 4 A double-channel wave-free screen changer shown includes a box body 3, a guide column 2, a wire mesh fixing base 6, a screw drive device 14 and a fixing plate 1, and rectangular feeding ports are provided on both sides of the box body. The mouth 10 and the discharge port 5, the upper and lower ends of the box are inwardly formed columnar chambers to form a material chamber 9, and the upper and lower chambers are non-communicative structures.

[0033] Two guide posts are provided at the feed port end of the box body, and one guide post is provided at the discharge port end of the box body, so as to facilitate taking out the screen mesh during the screen replacement process.

[0034] Two sets of guide sleeves are arranged on the guide column 2, and each set of guide sleeves is two and arranged diagonally.

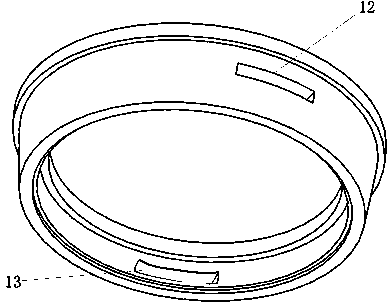

[0035] The guide sleeve is connected with a wire mesh fixing base 6 through fixing bolts. The main body of the wire mesh fixing base 6 is a circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com