Suspension steering device for hub direct-driving electric vehicle

A technology for electric vehicles and steering devices, applied to automatic steering control components, steering mechanisms, steering rods, etc., can solve problems such as reduced transmission efficiency, loss of power to wheels, deviation of driving directions, etc., to avoid lateral swing and structural design. Reasonable and large vibration reduction stroke effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

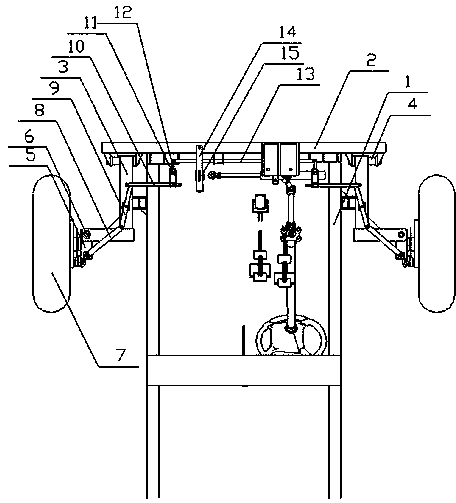

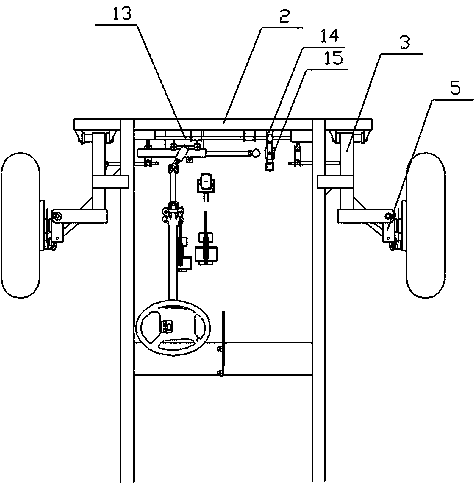

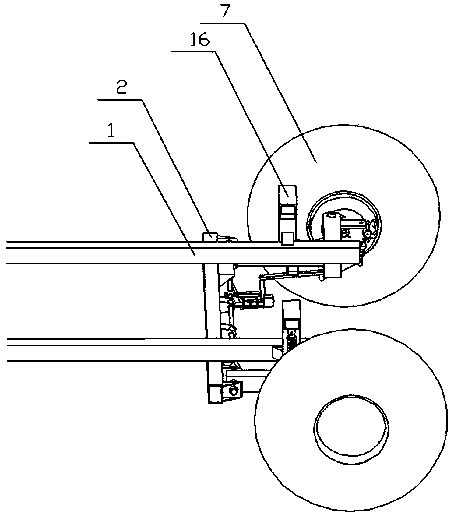

[0020] like Figure 1-Figure 6 As shown, this specific embodiment adopts the following technical solutions: it includes a longitudinal beam 1, a beam 2, a longitudinal cantilever 3, a horizontal shaft 4, a horizontal steering swing arm 5, a vertical shaft 6, wheels 7, an adjustment rod 8, a first horizontal hinge 9. Second horizontal strand 10, first vertical strand 11, second vertical strand 12, direction link 13, gyro swing arm 14, gyro 15, shock absorber bracket 16, elastic shock absorber 17, two longitudinal beams 1 A crossbeam 2 is horizontally arranged between them, and longitudinal cantilevers 3 are arranged symmetrically at both ends of the crossbeam 2, and one end of the two longitudinal cantilevers 3 is fixed on both ends of the crossbeam 2 by a horizontal shaft 4, and the movable ends of the two longitudinal cantilevers 3 are A horizontal steering swing arm 5 is installed, and the longitudinal cantilever 3 and the horizontal steering swing arm 5 are fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com