Packaging bag with V-shaped cold solder joint seam

A packaging bag and bag corner technology, applied to containers with multiple items, packaging, packaged food, etc., can solve the problems of incomplete adaptation, production and sales restrictions, and many operating steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The virtual weld processing adopts the virtual weld welding equipment disclosed in Chinese patent CN200620087996.5

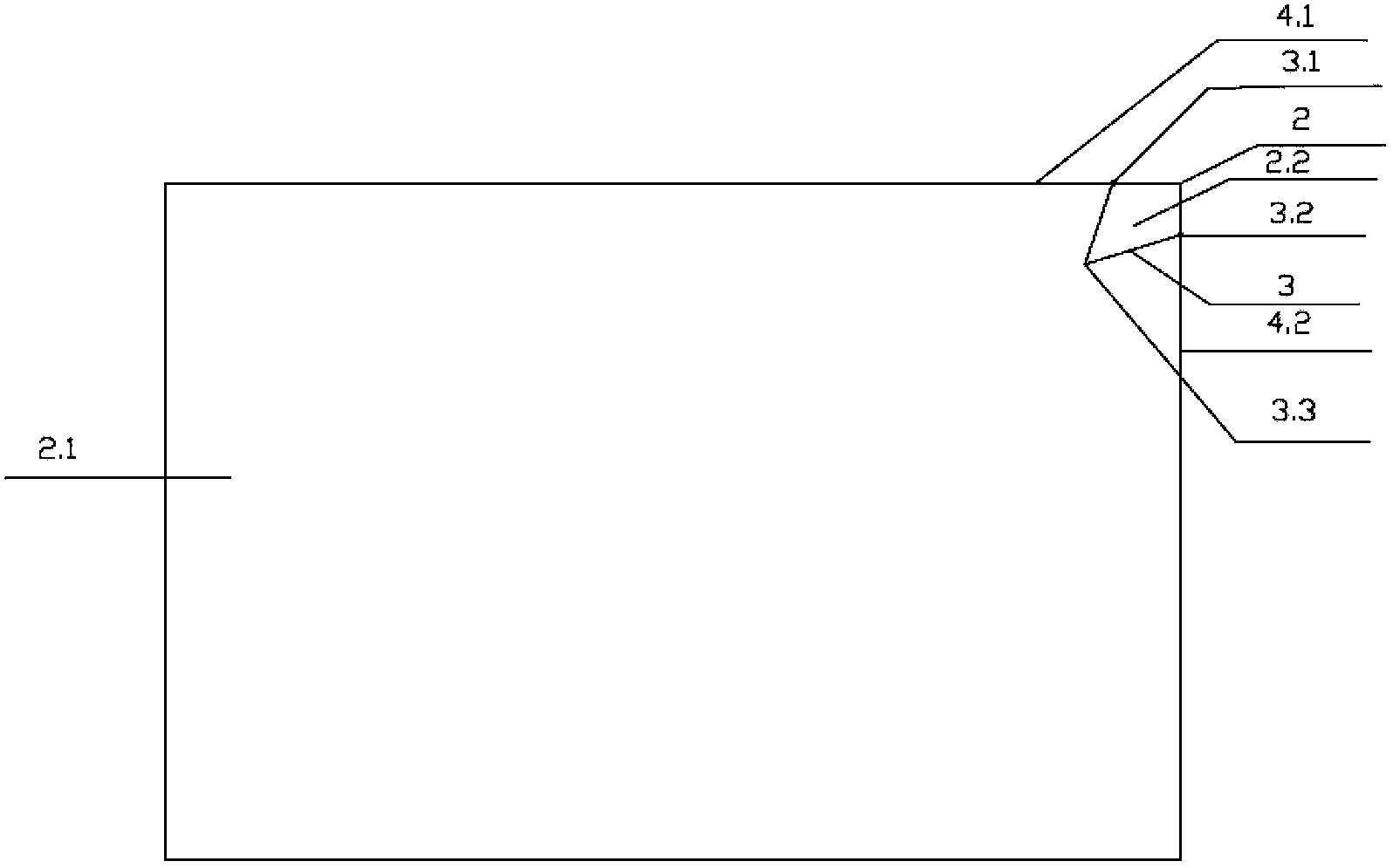

[0010] Such as figure 1 As shown, the dimensions of the rectangular packaging bag used are 10cm×15cm, and the virtual weld seam is close to the corner 2 of the bag. During production, the upper and lower ends of the packaging bag are sealed by heat and pressure respectively, and then the virtual weld seam 3 is welded on the bag. Seam 3 is a V-shaped line, and the two endpoints 3.1 and 3.2 are respectively located on the sides 4.1 and 4.2 of the packaging bag. The bottom angle α of the V-shaped virtual weld is 60°, and the angle bisector of the bottom angle is on the diagonal line of the packaging bag. It is 1.5cm away from the corner 2 of the bag. During the packaging operation, the liquid storage chamber 2.1 can be filled with milk and sealed; the yogurt starter can be added to the storage chamber 2.2 and sealed; the packaged milk can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com