Low-temperature-resistant oil-base ink

A low-temperature resistant, oil-based technology, used in inks, household appliances, applications, etc., can solve the problems of increasing writing cost, affecting writing speed, vulnerability and pen tip, reducing writing pressure, improving writing lubrication performance, Avoid the effect of oil on the nib

Inactive Publication Date: 2014-10-22

常熟市协新冶金材料有限公司

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, under the condition of low ambient temperature, such as winter, especially when the ambient temperature is lower than 10°C, due to the high viscosity, the ink supply will not be smooth, the writing will be laborious, and the writing will be broken or even blurred, which not only affects the writing speed, but also easily causes writer fatigue

Some people may ask such a question, that is to reduce the resin content and reduce the viscosity to 6000mpa·s or even 5000pa·s, which can avoid the situation of smooth writing under the condition of low ambient temperature, but it will cause the problem of losing sight of the other. Because when the viscosity is lower than 5000pa·s, the test shows that the lubricity of oil-based ink is significantly reduced and the pen tip is easily damaged. Once the pen tip is worn out, it cannot be used, and the pen core can only be replaced, which increases the writing cost.

In addition, if the viscosity is too low, it is easy for the ink to emerge from the nib, and the paper will be dirty and dirty.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

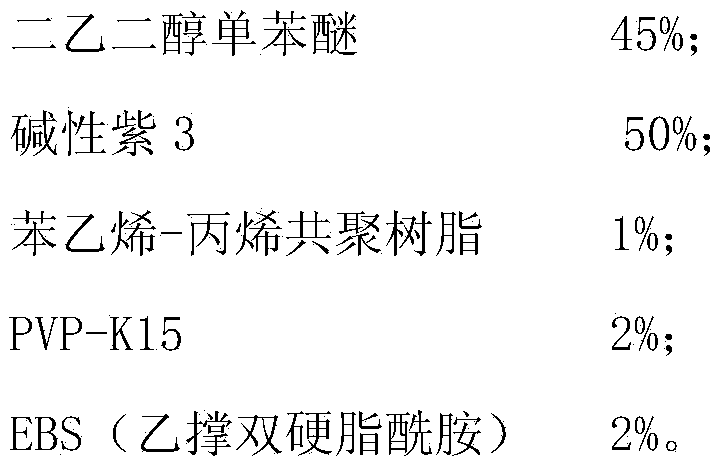

Embodiment 1

[0015]

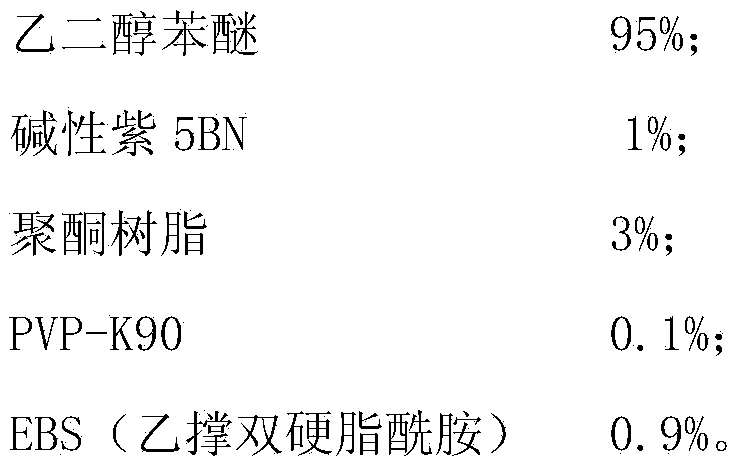

Embodiment 2

[0017]

Embodiment 3

[0019]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Login to View More

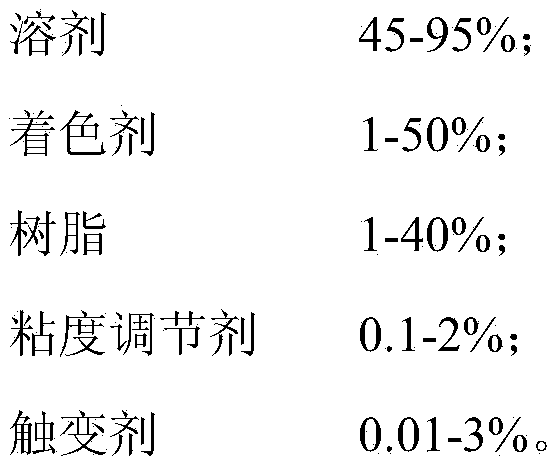

Abstract

The invention relates to a low-temperature-resistant oil-base ink, belonging to the technical field of writing inks. The ink is prepared from the following raw materials in percentage by mass: 45-95% of solvent, 1-50% of colorant, 1-40% of resin, 0.1-2% of viscosity modifier and 0.01-3% of thixotropic agent. The viscosity of the ink is 500-3000 mpa.s when the temperature is 25 DEG C and the shear rate is 500 S<-1>, and the viscosity is 1000-5000 mpa.s when the shear rate is 5 S<-1>; and thus, the ink can improve the writing lubricating property in a low-temperature environment, reduce the writing pressure and prevent the penpoint from bleeding, and can not have the phenomenon of broken lines.

Description

technical field [0001] The invention belongs to the technical field of writing ink, and in particular relates to a low-temperature-resistant oil-based ink. Background technique [0002] The oil-based ink that known ball-point pen is used usually is made up of organic solvent, coloring agent and resin, because the viscosity of this oil-based ink is between 6000-11000mpa s, therefore under the condition that ambient temperature is high as summer viscosity can reduce and It can meet the requirements of smooth ink supply when writing, and more specifically, there will be no intermittent or even white writing lines caused by insufficient ink supply. However, under the condition of low ambient temperature, such as winter, especially when the ambient temperature is lower than 10°C, due to the high viscosity, the ink supply will not be smooth, the writing will be laborious and prone to broken lines or even white spots, which not only affects the writing speed, but also easily causes...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D11/16C09D11/18

Inventor 沈国俭

Owner 常熟市协新冶金材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com