An automatic tester for thickness and compression recovery performance of textile products

A compression recovery and tester technology, applied in textiles, papermaking, textile material inspection, instruments, etc., can solve the problems of poor quality accuracy of test tableting, difficult operation, poor versatility of test instruments, etc., to ensure accuracy, avoid The effect of human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

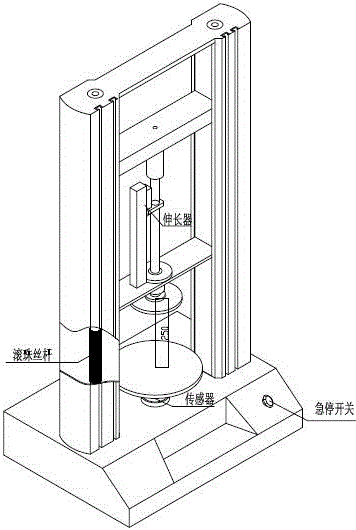

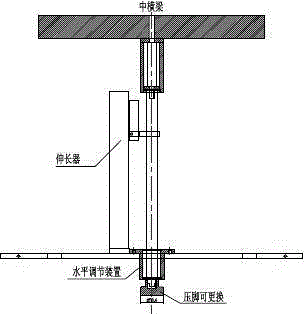

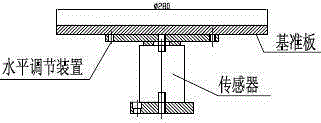

Image

Examples

Embodiment 1

[0059] When using the tester of the present invention to test the thickness of textile products, according to the requirements of relevant standards, configure and install presser feet of corresponding specifications, and return the presser feet to their original positions. And the recovery speed after the test is completed, 15 samples of different thickness types are tested. At the same time, re-test according to the relevant tester and device, the data is shown in the table below.

[0060] Table 1 Tester of the present invention compares with other testing device thickness tests (unit mm)

[0061]

Embodiment 2

[0063] When using the tester of the present invention to test the compression recovery performance of textile products, according to the requirements of relevant standards, a presser foot of 20cm × 20cm is configured and installed, and the presser foot is returned to its original position, and 5 pieces of glue-sprayed cotton batting are selected as test samples. Set the light pressure to 0.5kPa through the software control system, measure the thickness after 30s of pressurization time, stand still for 30s (including the process of lifting and returning the presser foot) and pressurize again, repeat this operation process 3 times. Set the weight to 1.0kPa, measure the thickness after 30 seconds of pressurization, and measure the thickness after standing for 3 minutes (the presser foot is quickly lifted), and repeat this operation process 3 times.

[0064] Refer to the GB / T 24442.1-2009A method, and use a heavy block to pressurize and manually operate the compression performance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com