A kind of thermal stability detection method of organic heat carrier

A detection method and thermal stability technology, applied in the field of petrochemical industry, can solve the problems of high detection cost, small difference in test results of heat transfer oil, slow detection speed, etc., and meet harsh test conditions, low requirements for heat treatment containers, and large difference in deterioration rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

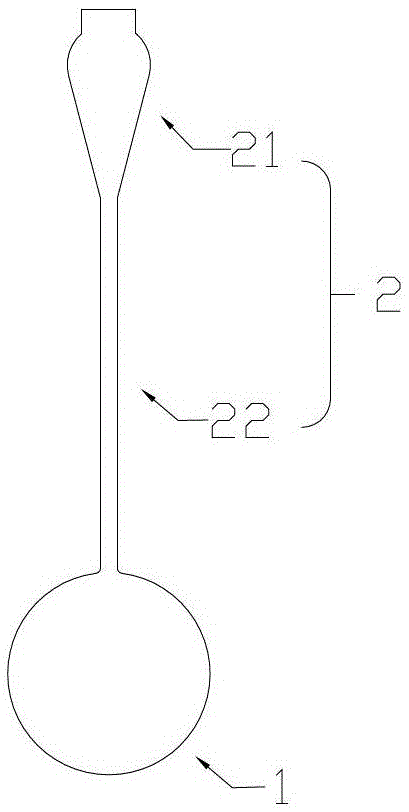

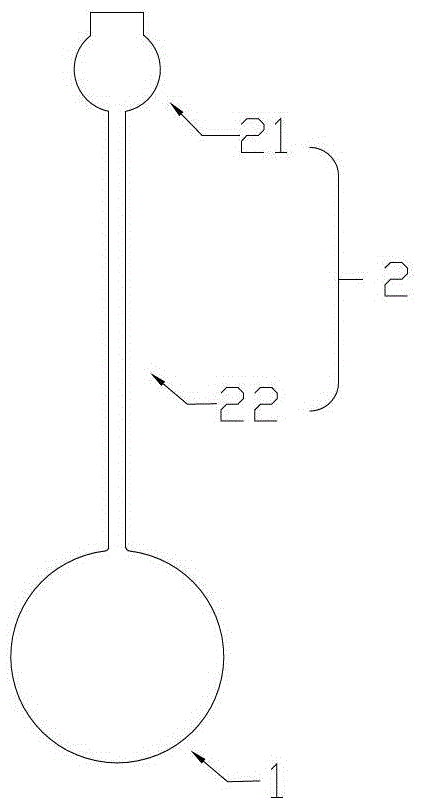

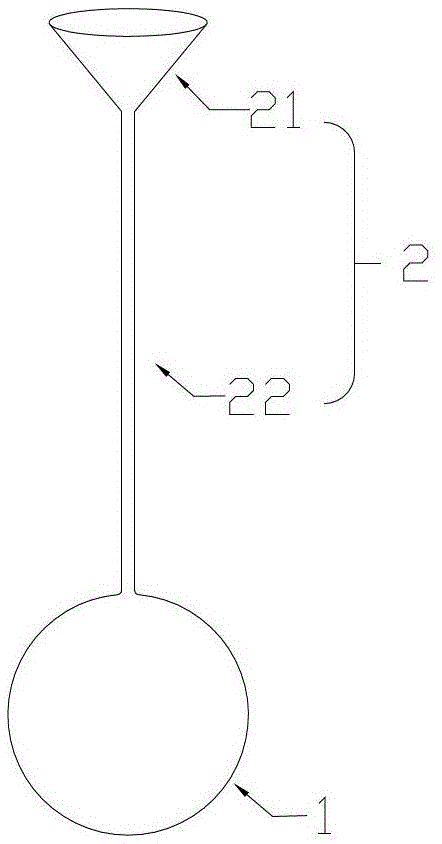

[0029] Collect commercially available heat transfer oil samples 1 and 2 (the maximum service temperature is 310°C, with the test report of GB / T23800-2009 organic heat transfer thermal stability test method) and Maxtor's MTYD310 mineral heat transfer oil (maximum service temperature both at 310°C), each 100mL was injected into the attached Figure 7 As shown, the specification is that the volume of the bottle body is 100mL, the length of the funnel neck is 750mm, and the inner diameter of the funnel neck is 6mm. The probe is placed in the temperature probe installation hole 3 to detect the temperature, and the oxidation interface, color, attachment, bottom precipitation, and light transmittance of the three are observed with the naked eye. After heating, the acid value and viscosity are measured. The results are as follows:

[0030] Maxtor MTYD310 mineral heat transfer oil is initially a light golden yellow transparent liquid, and the color deepens with time. After the test is ...

Embodiment 2

[0035] Collect commercially available synthetic aromatic hydrocarbon heat transfer oil samples 3 and 4 (both with a maximum service temperature of 300°C, with the test report of GB / T23800-2009 organic heat carrier thermal stability test method) and Maxtor's MTFD synthetic aromatic hydrocarbon heat transfer oil ( The maximum operating temperature is 300°C), each 100mL, respectively injected into a detection container with a bottle volume of 100mL, a funnel neck length of 750mm, and a funnel neck inner diameter of 6mm, heat the heat transfer oil in the bottle to 290°C and keep it for 400 hours, The temperature of the oxidation interface is 80°C±5°C. Observe the color, attachment, bottom precipitation, and light transmittance of the two with the naked eye. After heating, measure the acid value and viscosity. The results are as follows:

[0036] Maxtor MTFD synthetic aromatic heat transfer oil is initially light yellow transparent liquid, and the color deepens slightly with the hea...

Embodiment 3

[0041] Collect commercially available hydrogenated heat transfer oil samples 5 and 6 (maximum use temperature 310 ° C, with GB / T23800-2009 organic heat carrier thermal stability test report) and Maxtor's MTQD310 hydrogenated heat transfer oil (highest Temperature 310°C) each 100mL, respectively injected into the detection container with a bottle volume of 100mL, a funnel neck length of 750mm, and a funnel neck inner diameter of 6mm, and respectively added small metal blocks with the same material, shape, and size. Heat the oil to 310°C and keep it warm for 600 hours. The temperature of the upper oxidation interface is 120°C±5°C. Observe the color, attachment, bottom precipitation, and light transmittance of the two with the naked eye. After heating, measure the acid value and viscosity. The results are as follows:

[0042] Maxtor MTQD310 hydrogenated heat transfer oil is initially a colorless and transparent liquid, and the color deepens with the heating time. After the test, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com