Experimental method for evaluating damage of coal rock reservoir

An experimental method and technology of coal and rock, which can be used in material inspection products, soil material testing, etc., can solve problems such as failure to meet the requirements of coalbed methane damage evaluation, inability to truly and completely evaluate the degree of damage to various fluids, and achieve sustainable development. , the prospect of large-scale promotion and application, the effect of important social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

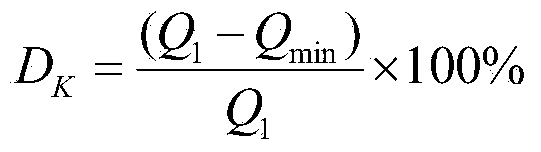

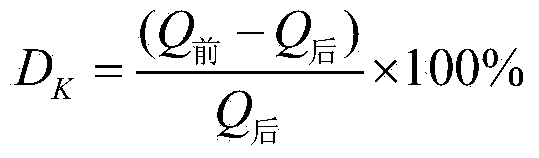

[0045] An experimental method for damage evaluation of coal and rock reservoirs includes a core stress sensitive damage test and a working fluid damage test.

[0046] During the exploitation of oil and gas reservoirs, with the production of fluid inside the reservoir, the pore pressure of the reservoir decreases, and the original force balance state of the reservoir rock changes. According to the theory of rock mechanics, changing from one stress state to another stress state will inevitably cause the compression or stretching of the rock, that is, the rock will undergo elastic or plastic deformation. At the same time, the deformation of the rock will inevitably cause changes in the rock pores and pore volume, such The reduction of pore volume, the closure of pore throats and fractures, etc., will greatly affect the seepage of fluid in it. Therefore, the change of the seepage capacity of the reservoir caused by the change of the net stress suffered by the rock lock is the resu...

Embodiment 2

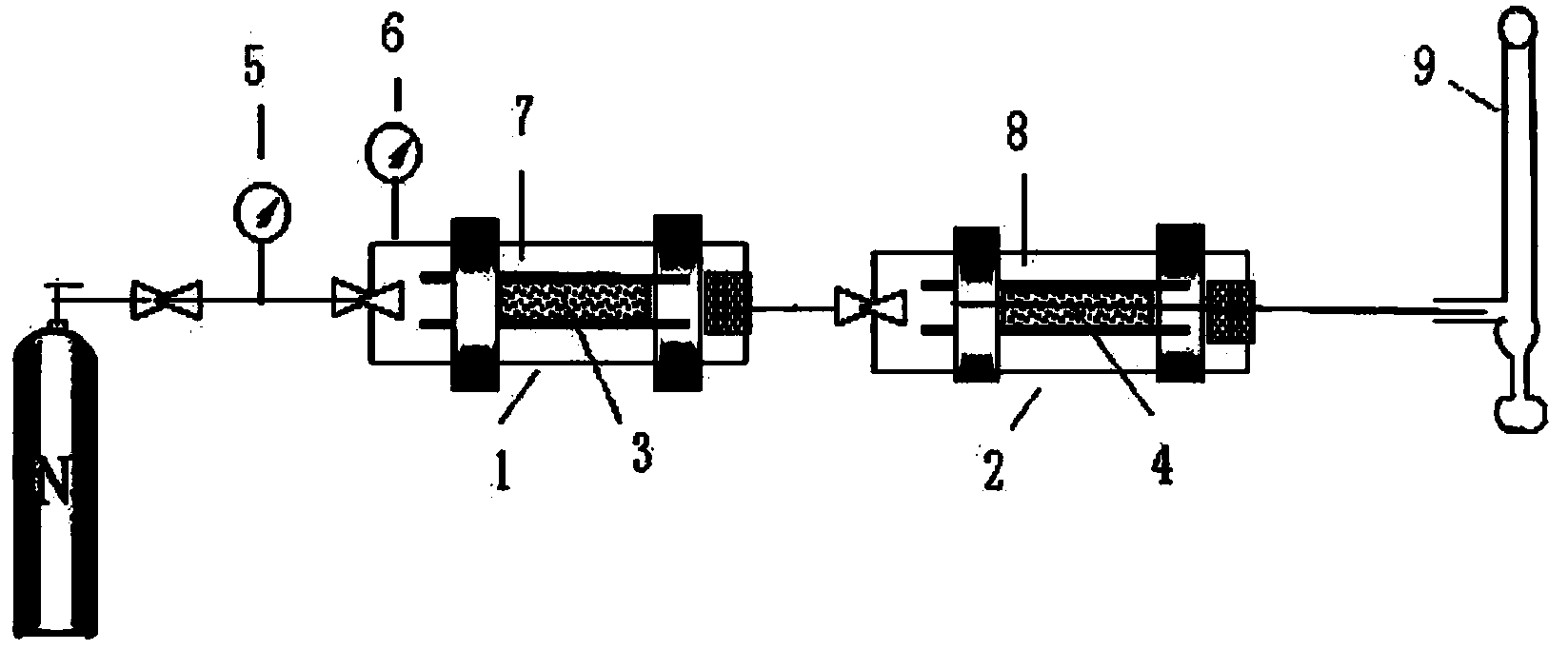

[0049] A new method of coal reservoir damage evaluation experiment, the schematic diagram of the experimental device is as follows figure 1 As shown, the stress-sensitive damage experiment of the present embodiment includes the following steps in turn:

[0050] Step 1) drill core, prepare coal rock matrix core and man-made fracture core according to SYT5358-2010 rock sample preparation method;

[0051] Step 2) measure the basic physical parameters of the coal rock matrix core and the artificial fracture core;

[0052] Step 3) Put the coal-rock matrix core into the first core holder, i.e. the natural column sample, put the artificial cracked core into the second core holder, i.e. the artificial seam sample, and combine the natural column samples with different permeability with the artificial sewing series;

[0053] Step 4) add confining pressure first, then add displacement pressure at the upstream end of the natural column sample to test the airtightness of the instrument; ...

Embodiment 3

[0071] A new method of coal reservoir damage evaluation experiment, the schematic diagram of the experimental device is as follows figure 1 As shown, the different stress damage experiments of the present embodiment include the following steps in turn:

[0072] Step 1) drill core, prepare coal rock matrix core and man-made fracture core according to SYT5358-2010 rock sample preparation method;

[0073] Step 2) measure the basic physical parameters of the coal rock matrix core and the artificial fracture core;

[0074] Step 3) Put the coal-rock matrix core into the first core holder, i.e. the natural column sample, put the artificial cracked core into the second core holder, i.e. the artificial seam sample, and combine the natural column samples with different permeability with the artificial sewing series;

[0075] Step 4) add confining pressure first, then add displacement pressure at the upstream end of the natural column sample to test the airtightness of the instrument; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com