Conduit rehabilitation pipe

A technology for regenerating pipes and pipes, which is applied in the direction of pipe laying and maintenance, hoses, pipes/pipe joints/fittings, etc., and can solve problems such as difficult handling and time-consuming work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

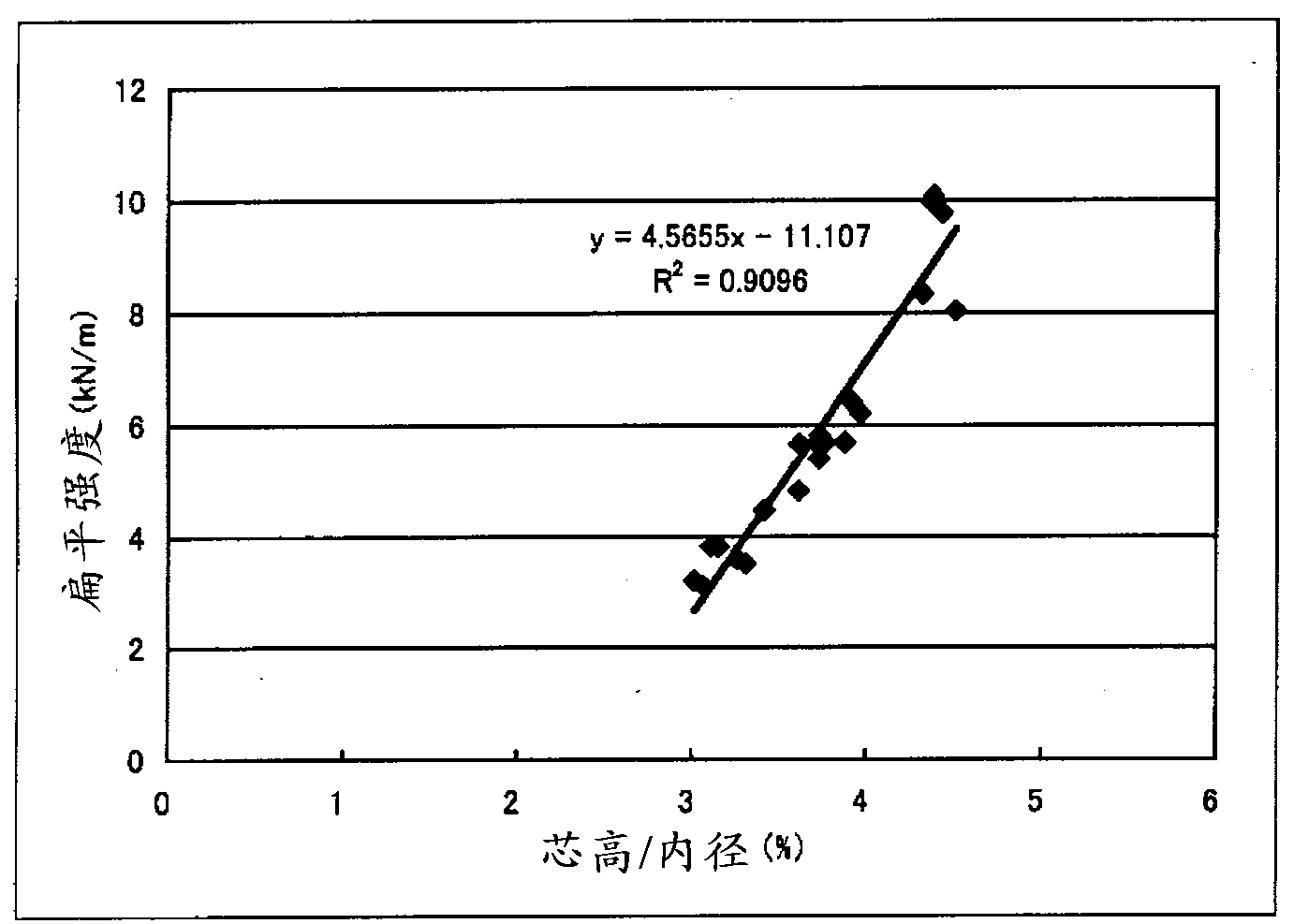

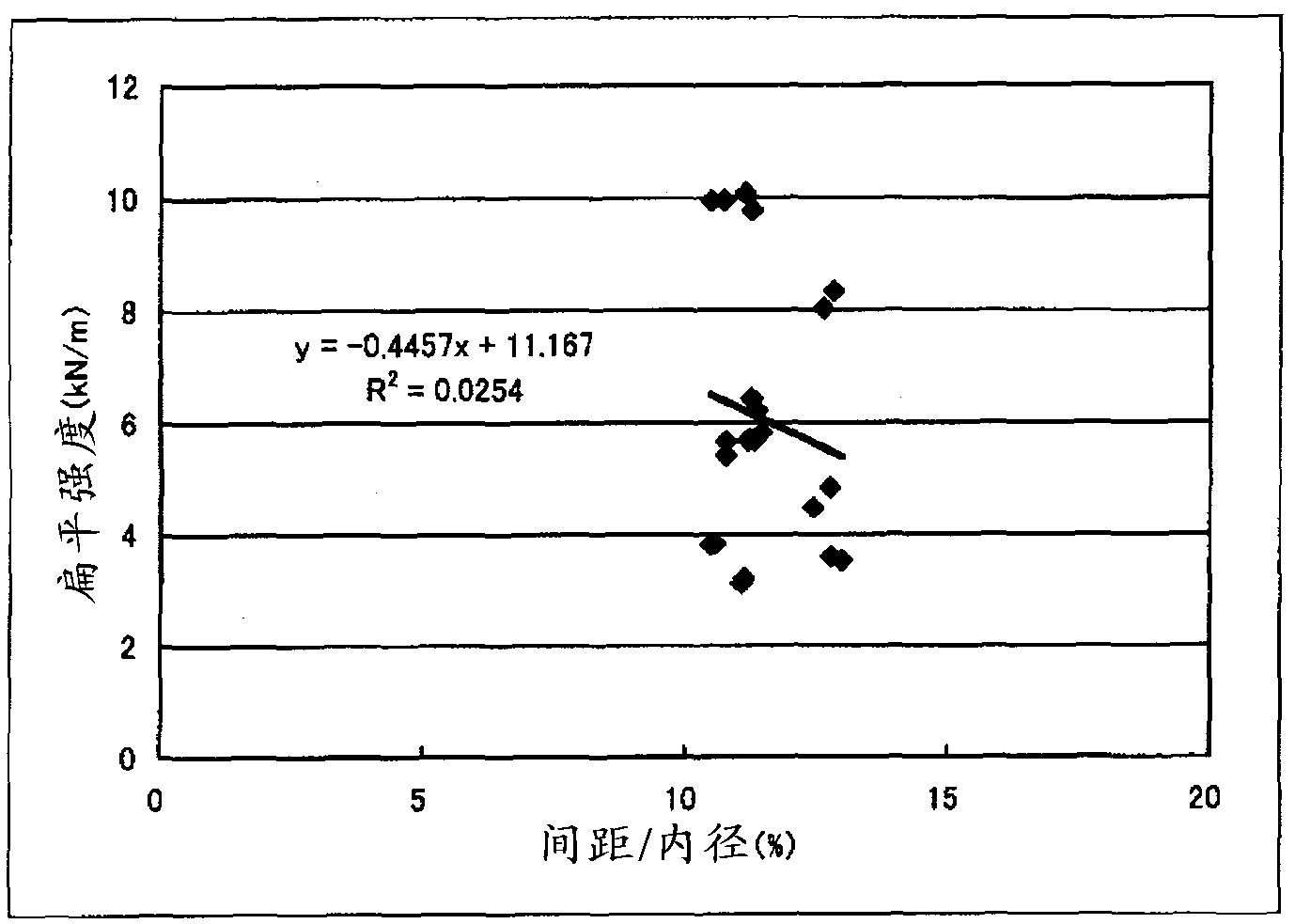

manufacture example 1

[0143] As the material of the lower side soft resin layer 5d, a mixture of LLDPE and EVA (ethylene vinyl acetate copolymer) is used, and as a material of the upper side soft resin layer 5e, a mixture of SEBS and PP is used, and they are respectively extruded into The tape shape is wound spirally (so that the edges overlap) sequentially around a substantially cylindrical core to form the lower soft resin layer 5d and the upper soft resin layer 5e . Next, use PPS as the hard resin, extrude it into rods having various substantially rectangular cross-sections with different heights and widths as the core material 5g, and use the same resin material as that of the upper soft resin layer 5e. Wrap to form the core material covering part 5f (thickness about 1mm), and the protrusion part 5c thus obtained is spirally wound on the outer surface of the above-mentioned upper side soft resin layer 5e (in other words, the outer surface of the straight pipe part 5b). ). Various regenerated p...

manufacture example 2

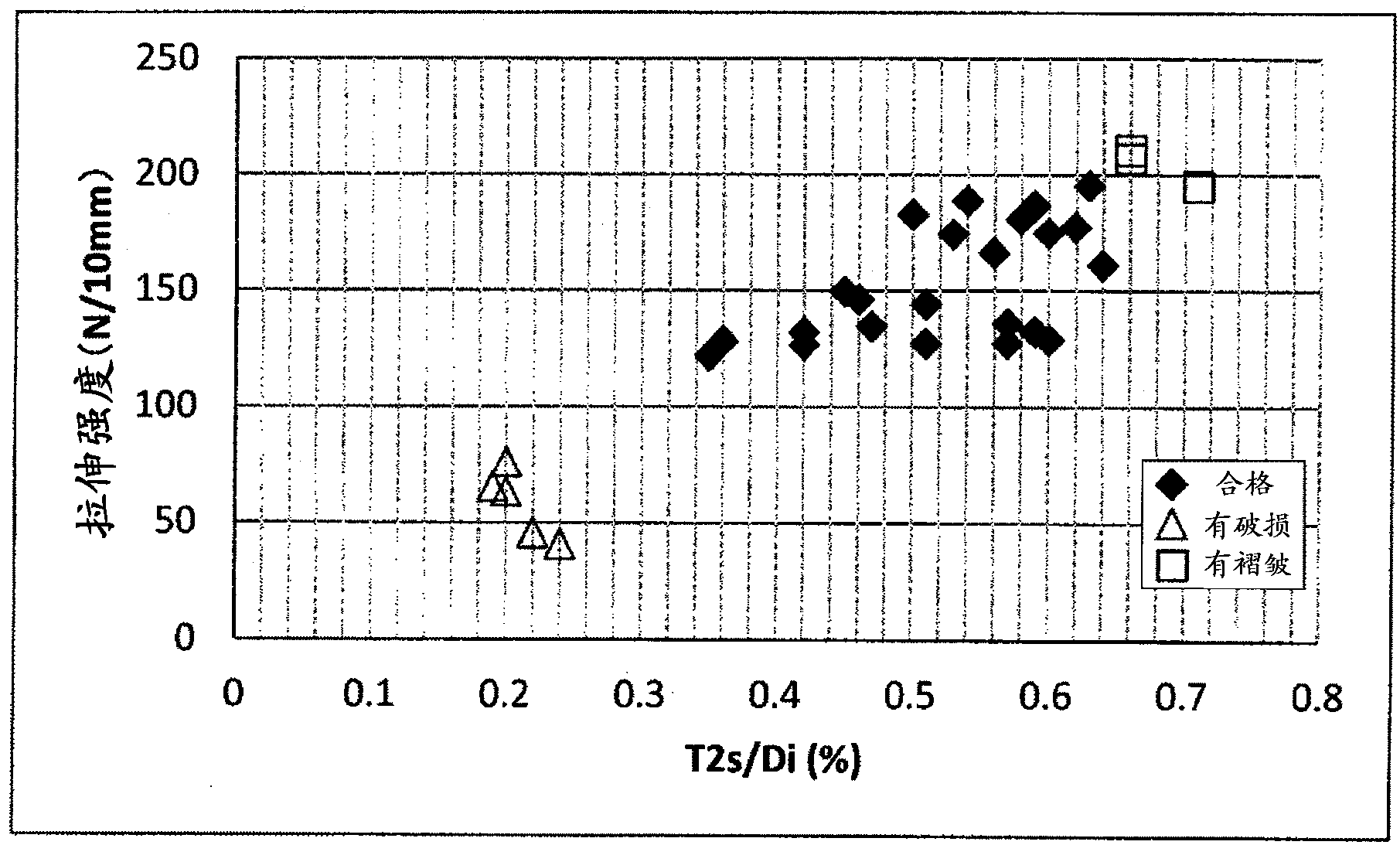

[0159] In the same manner as above, PPE was used instead of PPS, and regeneration pipe samples E to H having a nominal diameter of 250 mm were produced. Calculate the core height H, core width W, and spacing P relative to the inner diameter D based on the measured values of each sample i Each ratio of the core width W, pitch P relative to the core area (the product of the core height H and the core width W), the core height H, and the thickness T of the single-layer part 2s Relative to inner diameter D i of each proportion. In addition, the crushing strength of each sample was measured in the same manner as above, and the tensile strength was measured as follows. The results are shown in Table 5.

[0160] ·Tensile Strength

[0161] The tensile strength (N / 10mm) was measured according to "JIS K 7161".

[0162] [table 5]

[0163]

[0164] It is understood that even when PPE is used instead of PPS, the crushing strength of the regenerated pipe shows the height H from t...

manufacture example 3

[0168] In the same manner as above, a regeneration pipe sample having a nominal diameter of 250 mm was produced by setting the pitch P of the protrusions 5 c to 25 mm, and using PPS as the hard resin constituting the core material of the protrusions. Find the thickness T of the single-layer part 2s Relative to each sample inner diameter D i , and the tensile strength of each sample was determined as described above. The results are shown in Table 6.

[0169] [Table 6]

[0170]

[0171] From the above results, it became clear that in Production Example 3, as in Production Example 2, the thickness T of the single layer portion 2s Relative to regeneration tube inner diameter D i The ratio (%) becomes larger, and the tensile strength shows a tendency to increase ( Figure 15 ).

[0172]

[0173] The regenerated pipe samples obtained in Manufacturing Example 2 and Manufacturing Example 3 were bent at 90°, and the damage occurred on the outer peripheral portion outside th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com