Method for determining non-sinusoidal vibration technological parameters of crystallizer

A non-sinusoidal technology for process parameters, applied in the field of determining non-sinusoidal vibration process parameters of the crystallizer, can solve problems such as sudden changes and rigid shocks; if the acceleration is discontinuous, it will cause flexible shocks, etc., so as to improve the service life, large-scale promotion and use Value, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

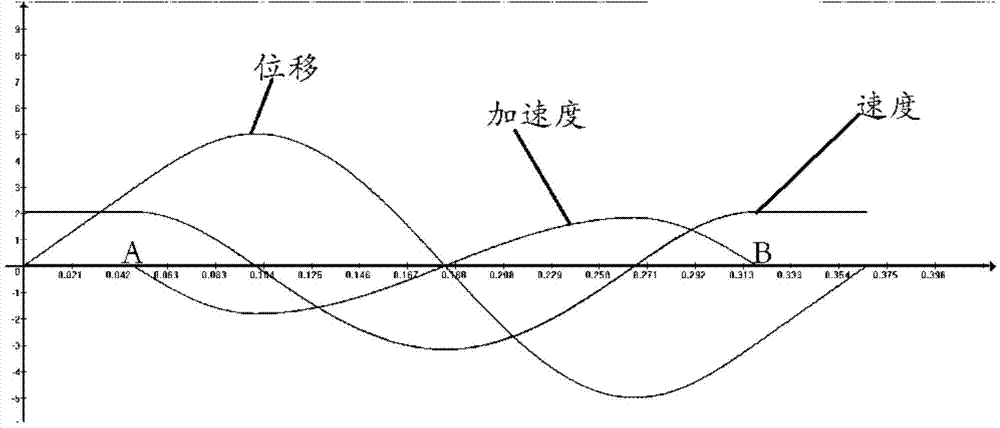

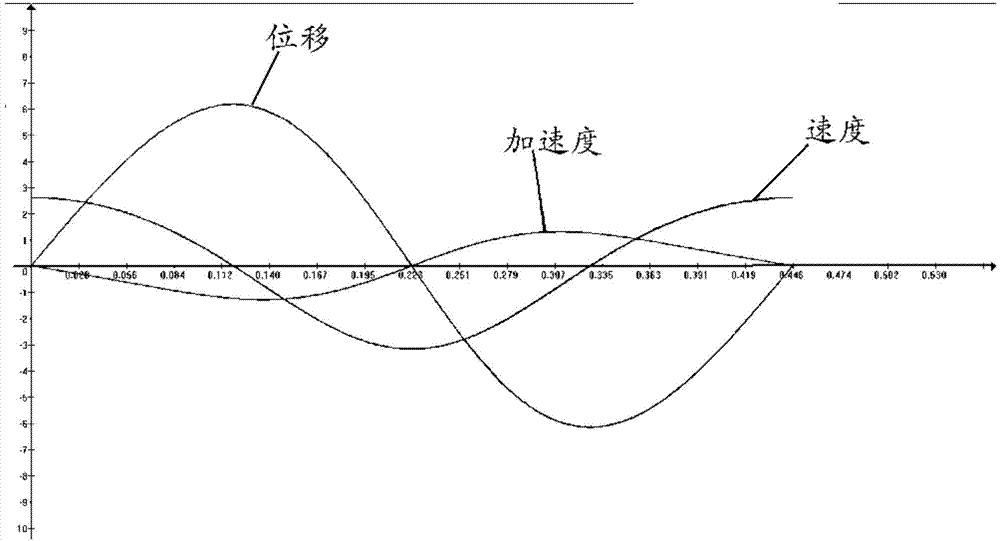

[0036] Such as figure 2 As shown, a method for determining the non-sinusoidal vibration process parameters of the crystallizer described in the embodiment of the present invention includes five non-sinusoidal parameters expressed by the overall function, which are (1) C1: vibration frequency at zero casting speed , Hz; (2) C2: vibration frequency / pulling speed coefficient; (3) C3: amplitude at zero casting speed, mm; (4) C4: amplitude / pulling speed coefficient; (5) α: non-sinusoidal factor, including The following four steps, namely

[0037] Step 1: The calculation formulas of position, velocity and acceleration are as follows:

[0038] ;

[0039] ;

[0040] ;

[0041] Among them: the vibration frequency is: ,in is the pulling speed;

[0042] The vibration amplitude is: ;

[0043] Step 2: When the time elapsed by the crystallizer movement is t m When , the speed of the crystallizer moving downward is equal to the casting speed, and the expression of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com