Drill point grinding and detecting system and detecting method and drill point locating device

A technology of detection system and fixing device, which is applied in the direction of grinding device, grinding machine tool, drilling/drilling equipment, etc., which can solve the problems of increased cost, waste of cost, and inability to position the drill bit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

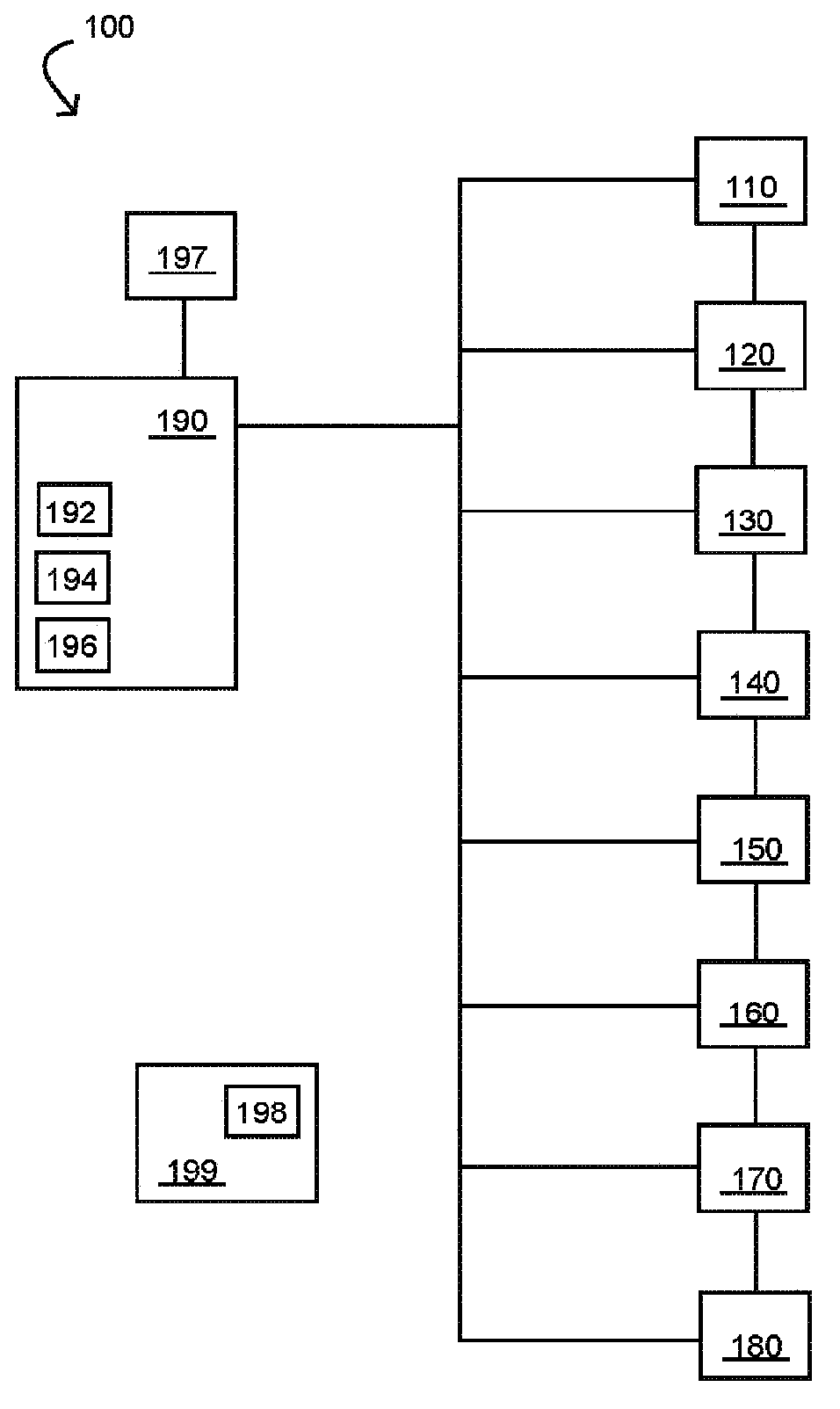

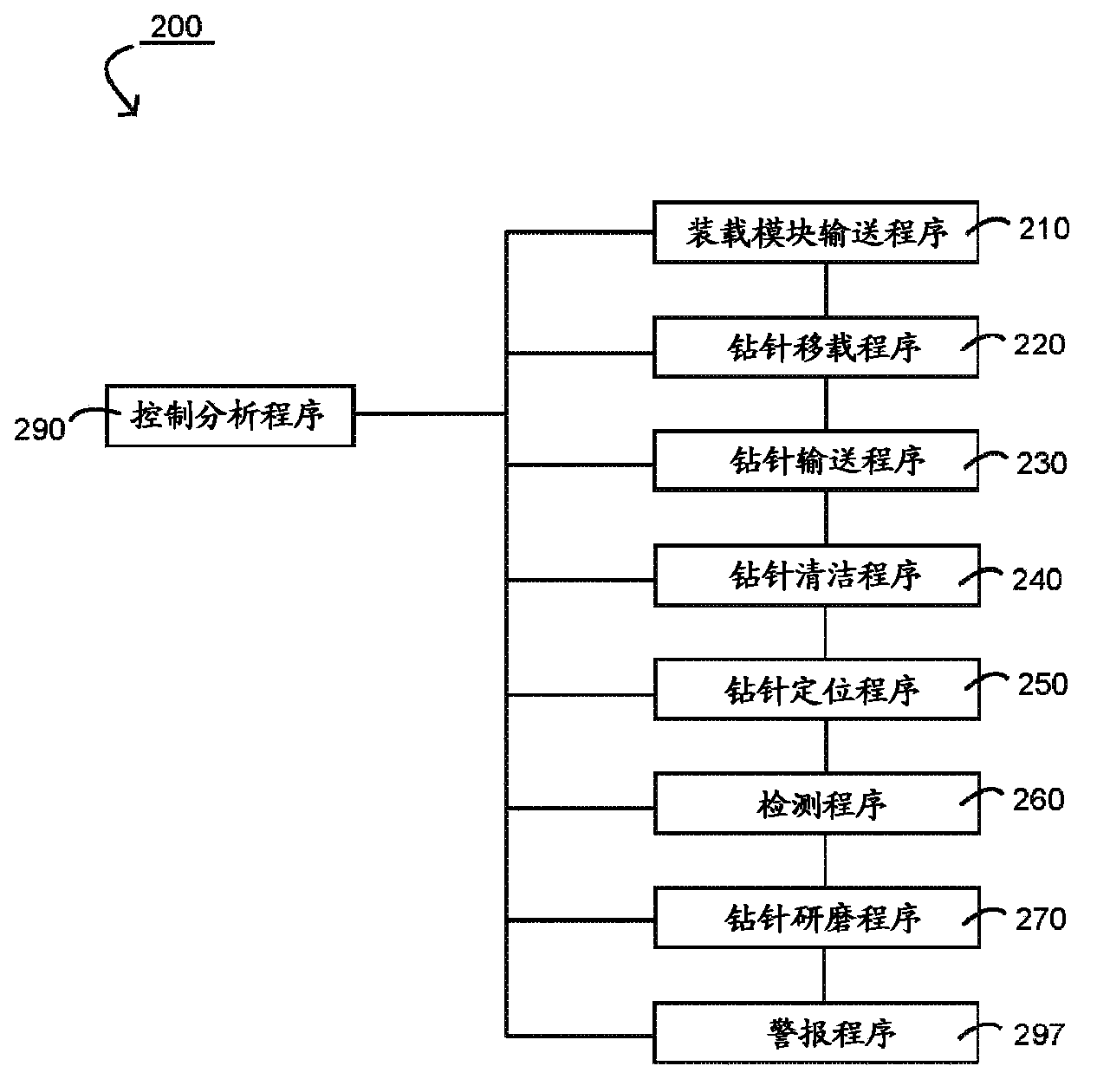

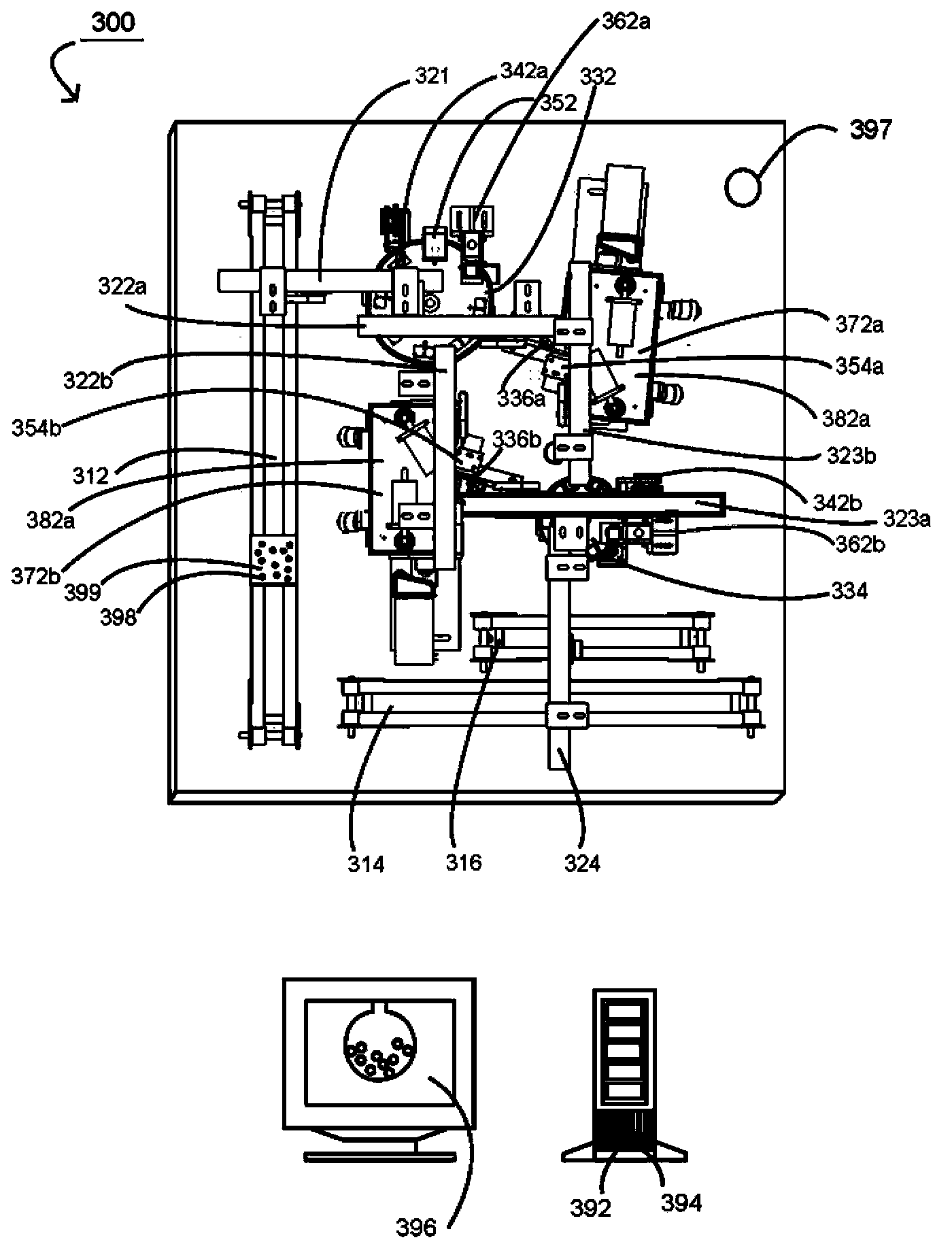

[0113] The research direction of the present invention is the grinding detection technology of the drill grinding detection system. In order to thoroughly understand the present invention, the detailed structure, components and method steps will be provided in the following description. In other instances, well-known structures and elements thereof have not been described in detail in order not to unnecessarily limit the invention. In addition, in order to provide a clearer description and enable those skilled in the art to understand the content of the invention, the various parts in the illustrations are not drawn according to their relative dimensions, and the ratio of certain dimensions to other relevant dimensions will be highlighted The exaggerated and irrelevant details are not fully drawn in order to simplify the illustration. The preferred embodiments of the present invention will be described in detail as follows, but in addition to these detailed descriptions, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com