Splined wheel hub and machining method thereof

A splined wheel and wheel hub technology, which is applied in the field of wheel hubs, can solve problems such as joint gaps, small force capacity, and difficulties, and achieve the effects of reliable transmission and braking, reliable use, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

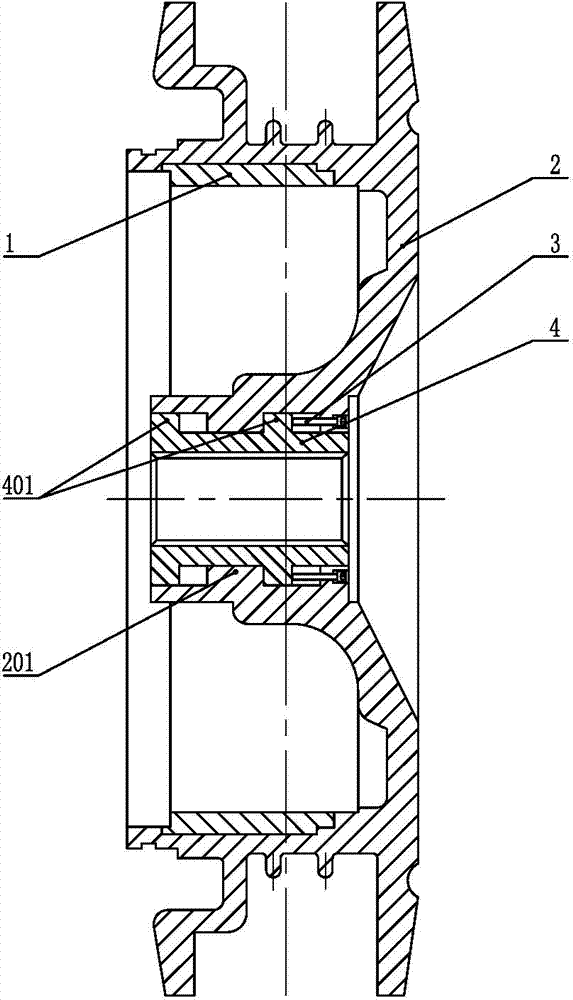

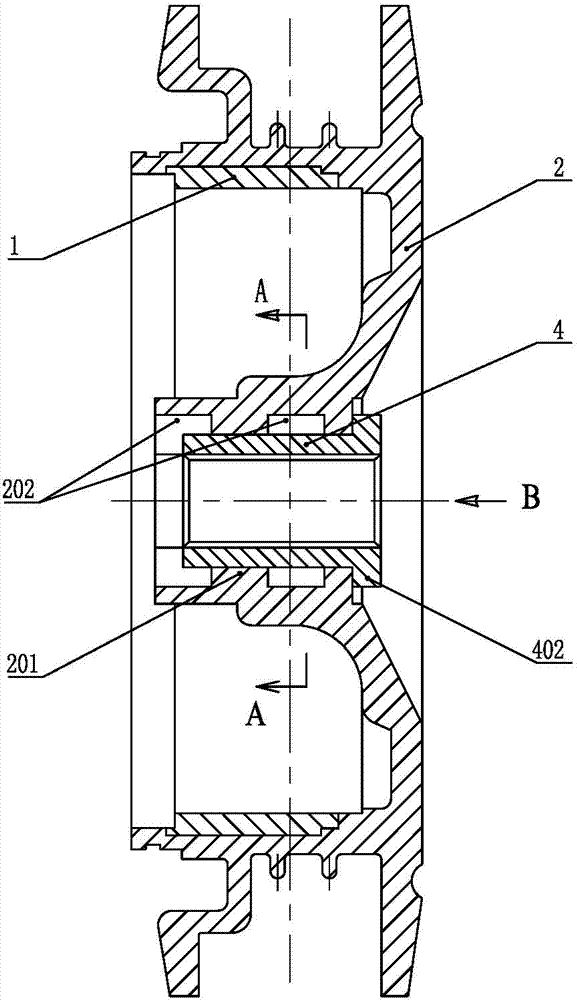

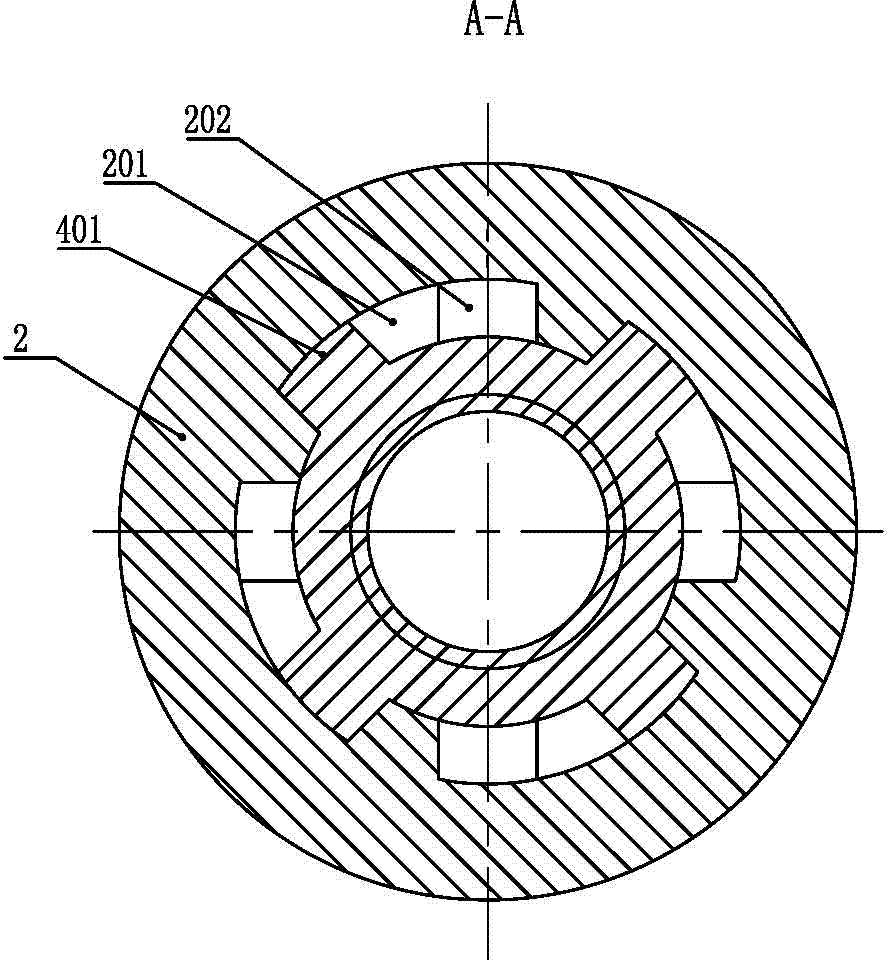

[0028] Such as Figure 1-9 As shown, it is a hub with 4 splines, including a hub body 2, a spline 4 is embedded in the center of the hub body 2, a brake iron ring 1 is arranged on the hub body 2 coaxially with the spline 4, and the inner ring of the spline 4 is provided There are several tooth-shaped keys, and the outer periphery of the spline 4 is provided with a layer of outer layer convex keys 402 and two layers of inner layer convex keys 401, the outer layer convex keys 402 correspond to the outside of the hub body 2, the outer layer convex keys 402 and the inner layer convex keys The keys 401 are respectively evenly distributed in four groups in the circumferential direction. The phase difference between each group of the outer convex keys 402 is 90°, and the phase difference between each group of the inner convex keys 401 is also 90°. The outer convex keys 402 The phase difference between the convex key 401 and the inner layer is 45°. The inner convex keys 401 of differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com