Electric hydraulic pump for vehicle power steering

A vehicle power and electro-hydraulic pump technology, applied in the field of hydraulic components, can solve problems such as failure to achieve power adjustment, large energy reactive power loss, and decreased operational stability, and achieve the effects of reducing energy consumption, reducing emissions, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

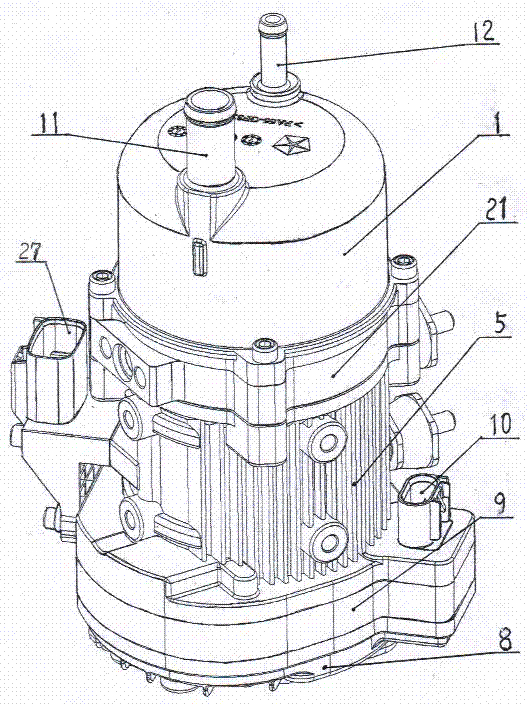

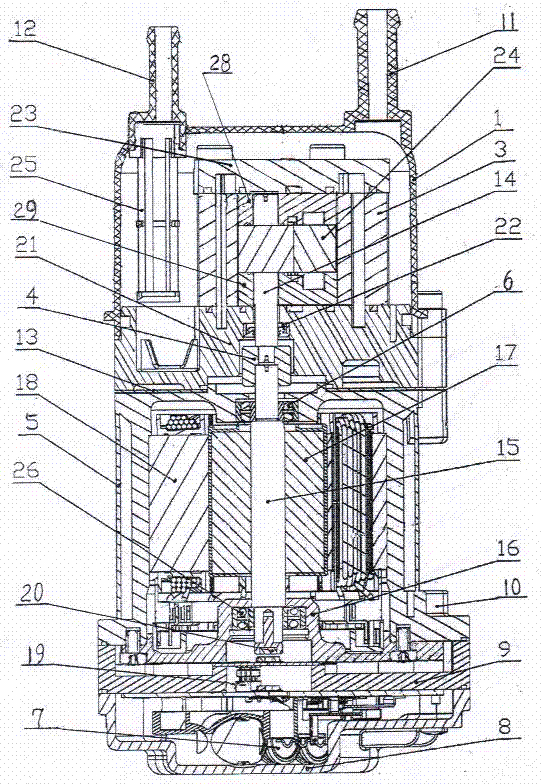

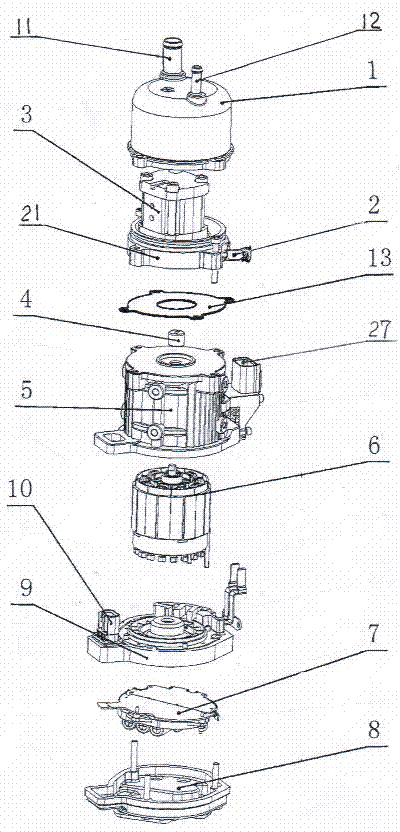

[0011] Examples, see attached Figure 1~3 , the side surface of the front end cover 21 of the vehicle power steering electro-hydraulic pump is threadedly equipped with a pressure relief valve 2, and the middle of the front end cover 21 is fixedly connected with the hydraulic pump body 3 and the front pump cover 23 with bolts. Seat ring one 28, seat ring two 29, driving gear 14, driven gear 24 are respectively housed in the pump body 3 of the hydraulic pump, and the upper and lower shaft ends of the driving gear 14 and the driven gear 24 are movable respectively on the seat ring one 28. On the seat ring 2 29, the driving gear 14 and the driven gear 24 are engaged in transmission connection. The oil pot 1, the front end cover 21, and the housing 5 are fixedly connected by bolts. A gasket 13 is installed between the front end cover 21 and the housing 5. The oil pot 1 is provided with an oil return port 12 and an oil filling port 11 respectively. An oil strainer 25 is fixedly ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com