Production technology of guide wheel body

A production process and a technology of guide wheels, which are applied in the field of production technology of guide wheel bodies for crawler tracks, can solve the problems of complicated processes and waste of materials, and achieve the effects of high material density, improved service life and good service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the drawings and specific embodiments.

[0046] A production process of a guide wheel body includes the following steps:

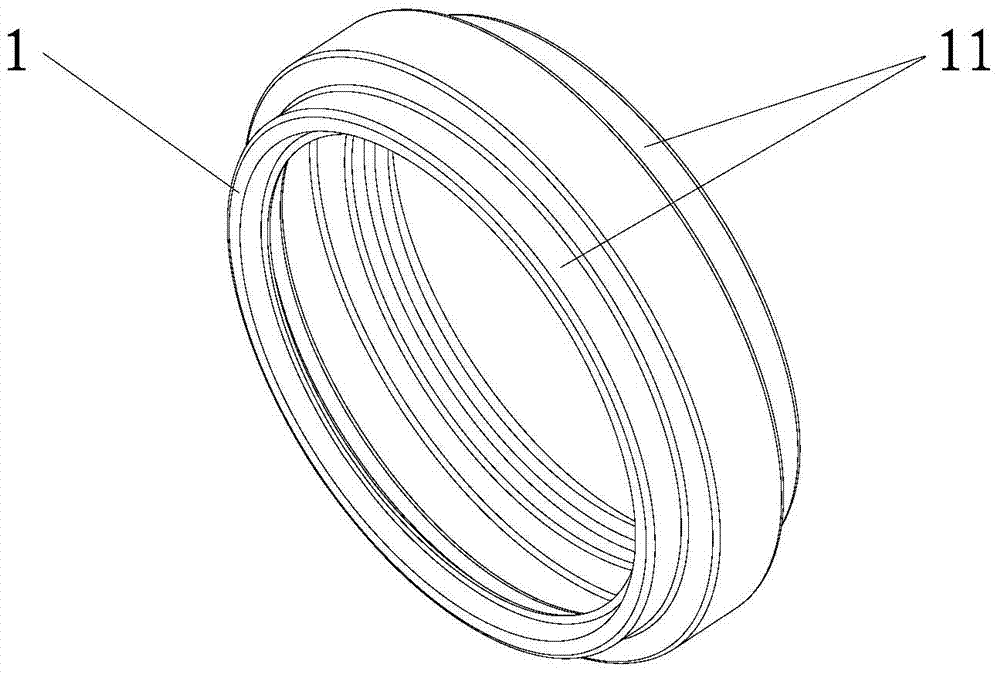

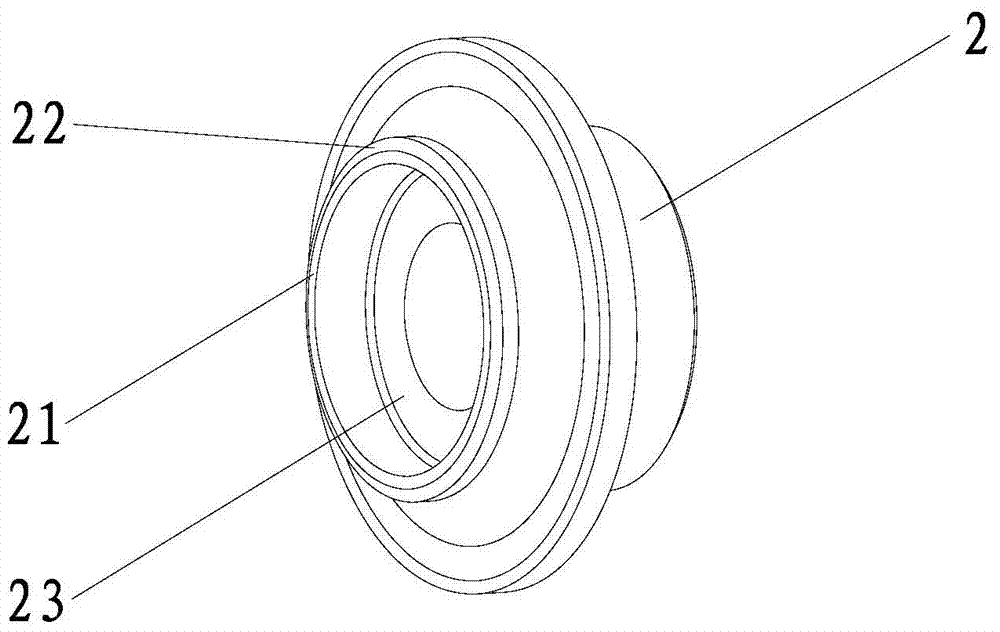

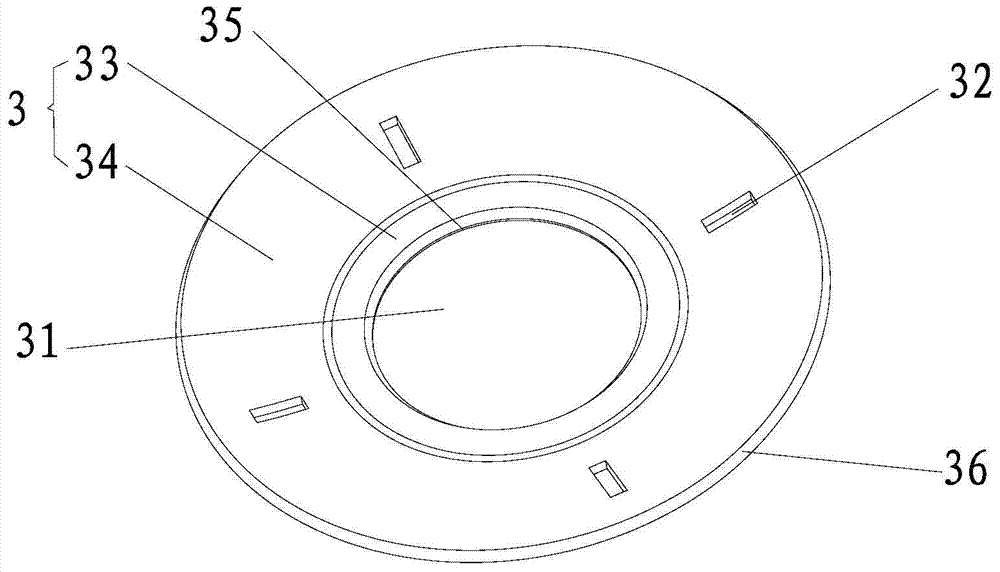

[0047] S1: Make the rim, cut a quantitative carbon alloy structural steel billet, place it in a heating furnace and heat it to 1150°C-1250°C, and then place it in the forming mold of the roller compactor for rolling to obtain the rim. The rolled rim has a higher density and a more uniform wall thickness. The molding die of the roller compactor has a cavity corresponding to the shape of the rim. The specific carbon alloy structural steel model can be selected according to needs. The alloy structural steel selected in this embodiment is 40Mn2. For the wheel body of the guide wheel with a larger diameter, because it is mainly used for large-scale equipment, it needs to be loaded The pressure is greater, and the alloy structural steel here is preferably 35 chromium-molybdenum alloy s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com