Bottle cap and bottle plug for pouring liquid

A bottle cap and bottle stopper technology, applied in the field of bottle caps and bottle stoppers, can solve the problems of easily polluting the environment, more solvent volatilization, easy to pour and sprinkle, etc., and achieve the effects of not easily destroying the environment, less solvent volatilization, and not easy to spill liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 Simple and easy bottle stopper for pouring liquid

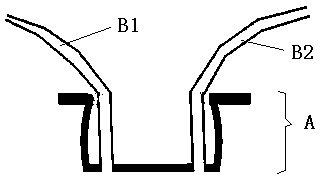

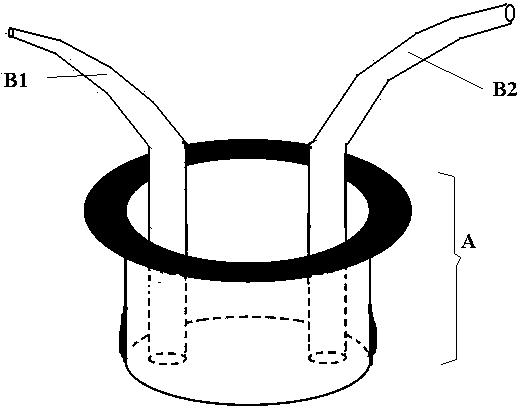

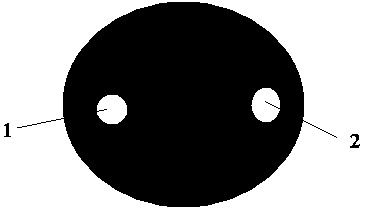

[0036] See attached figure 1 , 2 , 3, where A is the plug body, and B1 and B2 are the pipelines. B1 and B2 communicate with the bottom of the plug body, and extend in two different directions outside the plug body. The diameter of the tip of B1 is thinner, and the diameter of the tip of B2 is slightly thicker. The preparation material is plastic, and the straight diameter of the lower part of the plug body A Not the same, the diameter of the lower edge is slightly smaller, and the diameter of the middle is slightly larger.

[0037] This bottle stopper can directly plug the bottle body Y such as reagent bottles during operation. The elasticity of the plastic material makes the bottle stopper not easy to fall off. According to the flow rate and flow rate of the poured liquid, select a pipeline to align with the other bottle body and slowly Controlled inclination for pouring. After the pouring is complete...

Embodiment 2

[0038] Example 2 Ground-mouth stopper for pouring liquid

[0039] See attached Figure 4 , where A is the ground plug body, A1 is the outer ground part of the ground plug body, B11 is the outer ground part of the pipeline B1, B21 is the outer ground part of the pipeline B2, C11 is the ground small cover C1 C21 is the grinding part of the small cover C2, C11 is matched with B11, C21 is matched with B21, B1 and B2 communicate with the bottom of the plug body, and extend in two different directions outside the plug body , the tip diameter of B1 is thinner, and the tip diameter of B2 is slightly thicker. The preparation material of this product is glass.

Embodiment 3

[0040] Example 3 A screw cap for pouring liquid formed by combining two materials and three components

[0041] See attached Figure 5 , 6 as shown, Figure 5 The B1 and B2 pipelines in the circuit are not bent, so that it is convenient to put A2 on A1, and then bend B1 and B2. Figure 6 As shown, A1, A2, B1, and B2 are combined to form a screw cap, and a flange gasket A3 is used to cover the screw bottle body Y, and the purpose of dumping can be realized after tightening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com