Molecular sieve regeneration method in acetone continuous dehydration production process

A production process and molecular sieve technology, applied in the separation method, filter regeneration, separation/purification of carbonyl compounds, etc., can solve the problems of high input cost and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with embodiment.

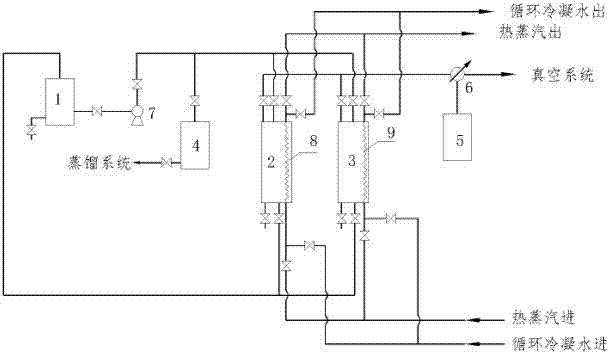

[0021] figure 1 It is a process device diagram of the molecular sieve regeneration method in a kind of acetone continuous dehydration production process of the present invention, and its concrete process steps are:

[0022] 1) Dehydration of the acetone stock solution

[0023] The acetone stock solution with higher water content is pumped into the first molecular sieve dehydrator 2 with the circulating pump 7, and then returned to the acetone stock solution storage tank 1 to continue dehydration; when the molecular sieve in the first molecular sieve dehydrator 2 is saturated and adsorbed, Close the ketone inlet and outlet valves of the first molecular sieve dehydrator 2, pump acetone that needs to be dehydrated into the second molecular sieve dehydrator 3 through the circulation pump 7, and flow back to the acetone stock solution storage tank 1 to continue dehydration;

[0024] 2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com