Automobile exhaust pipe noise elimination processing method

A technology for noise elimination and automobile exhaust, which is applied in the direction of mufflers, engine components, machines/engines, etc. It can solve problems such as limited scope of application, large power loss of mufflers, and short service life of mufflers, so as to reduce the residual air flow Possibility, effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

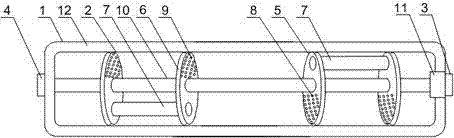

[0021] Such as figure 1 As shown, the noise elimination processing method of the automobile exhaust pipe of the present invention includes the following steps. First, the airflow is introduced into the breather pipe 10 through the air inlet 3, and the pneumatic control valve 11 installed at the air inlet 3 can be adjusted according to the air flow. When the air flow exceeds a certain limit, the pneumatic control valve 11 opens, so that the air flow directly enters the space formed by the first partition plate 5 and the muffler chamber 2 from the air inlet 3. Part of the air flow enters the space between the second partition plate 5 and the baffle 6 through the connecting pipe 7, and the remaining part of the air flow is silenced step by step by the through holes 8 on the two partition plates 5. The air flow from the air inlet 3 suddenly enters from a small space environment into a larger space environment. Only a few frequency sound waves near the natural frequency of the throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com