Electric car air conditioning system with air source heat pump

An air source heat pump and electric vehicle technology, which is applied in the field of refrigeration and air conditioning, can solve the problems that affect the safety of the system operation, the low suction capacity of the compressor, and the high exhaust temperature, so as to improve the heating capacity and heating efficiency and reduce the exhaust gas. Effects of temperature and extended use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

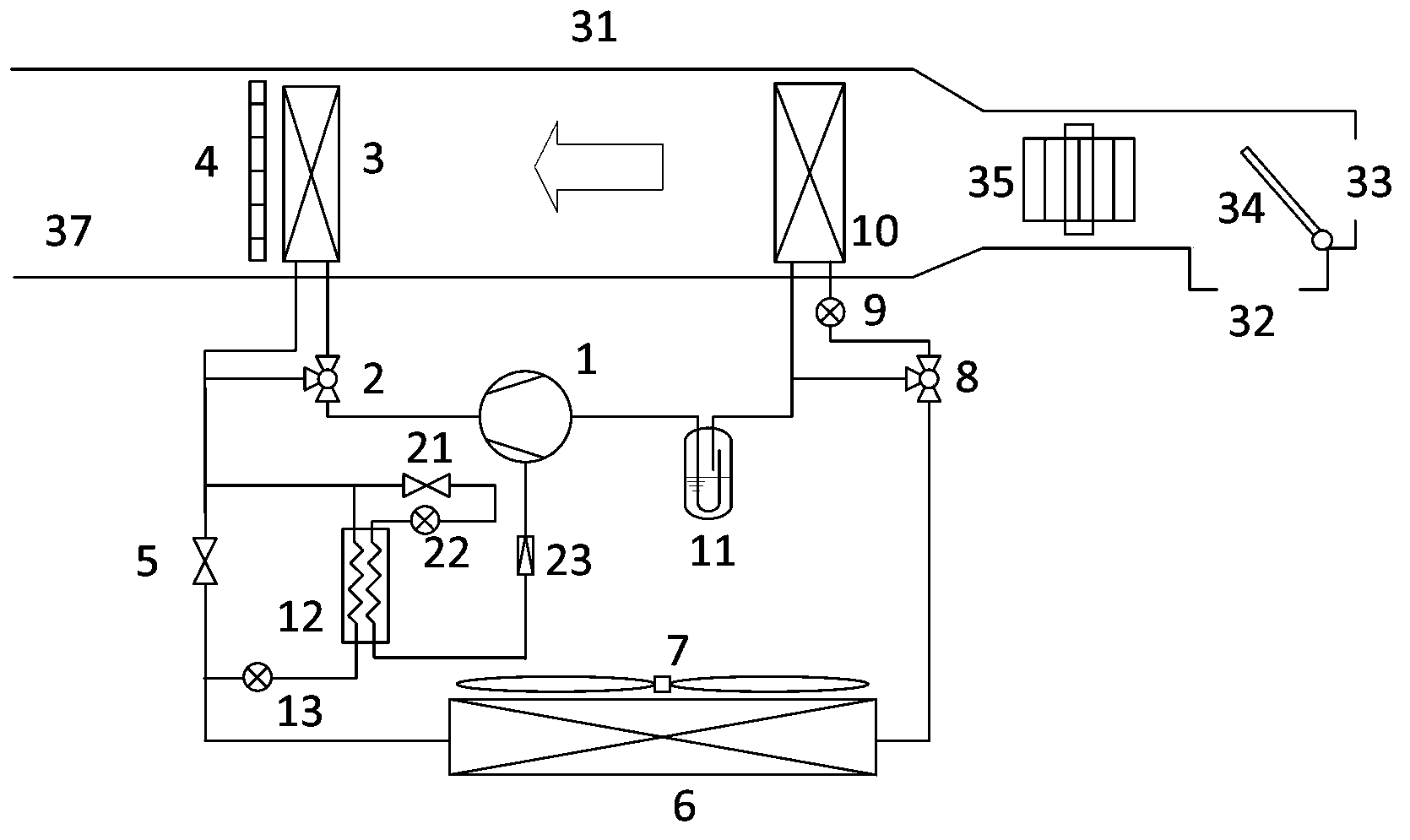

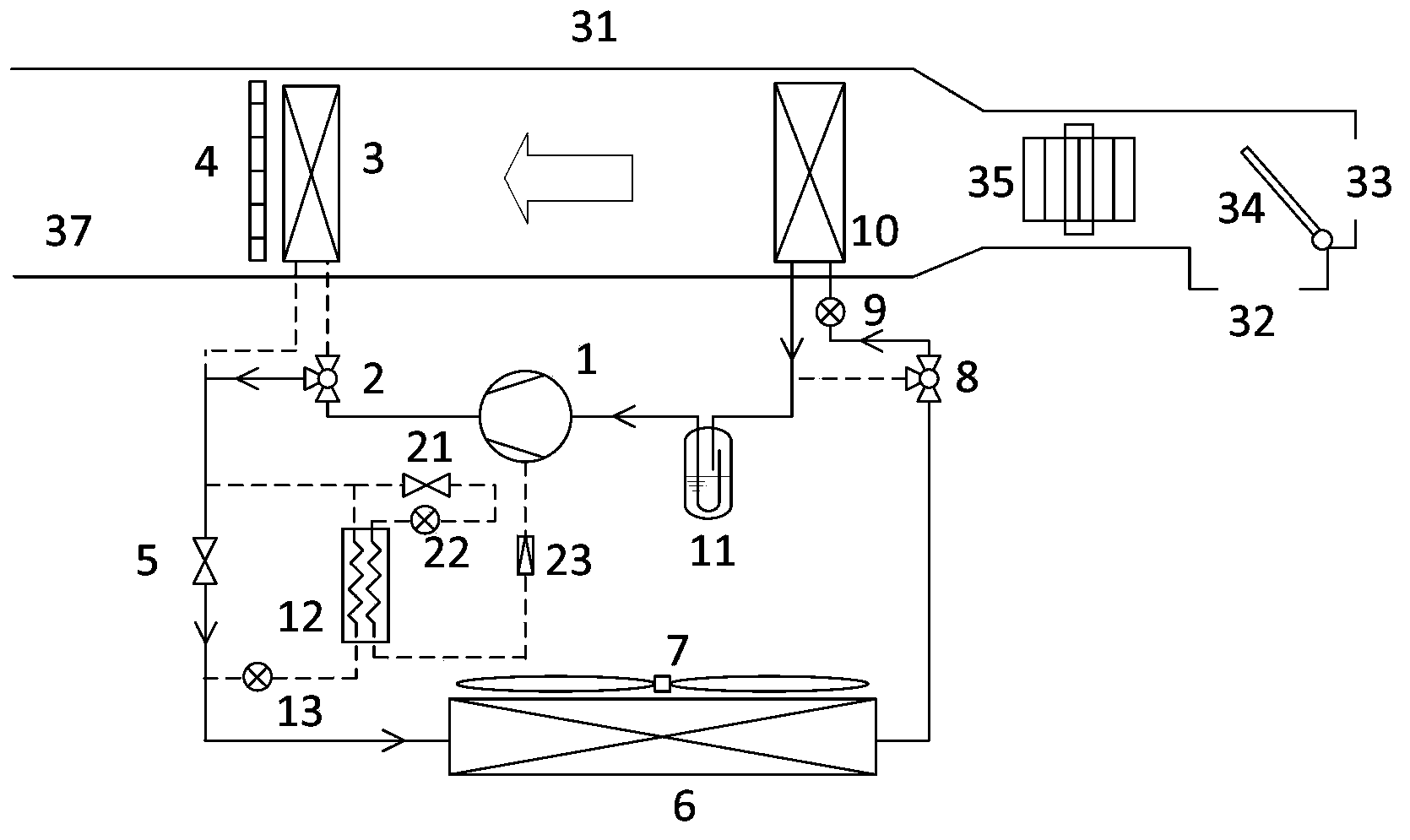

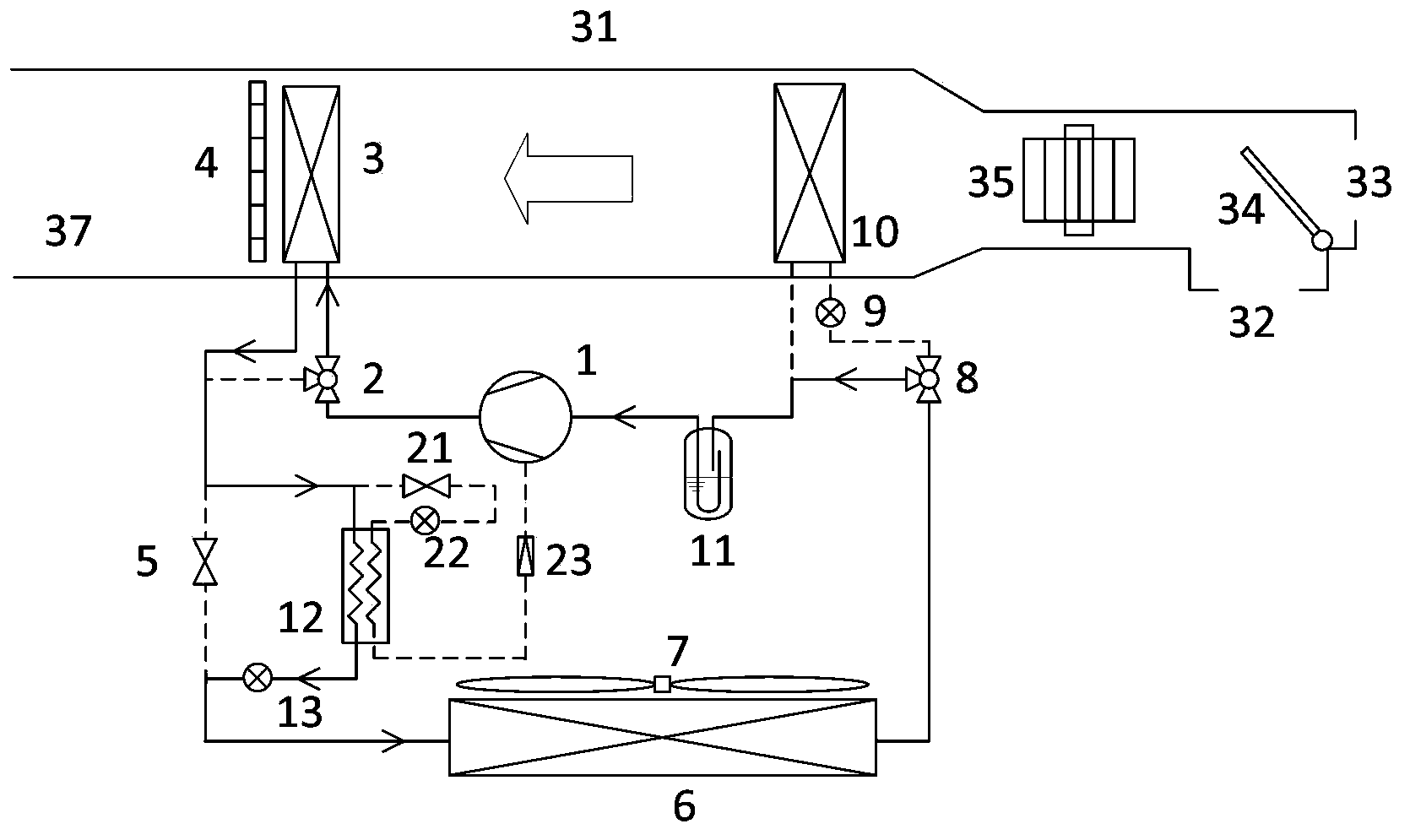

[0032] like figure 1 The electric vehicle air conditioning system shown in the figure adopts low-temperature air-source air-conditioning heat pump technology to realize the conversion of three modes: refrigeration, conventional heating and low-temperature heating; 3, the indoor evaporator 10 set on the return air line of the compressor 1, the outdoor heat exchanger 6 set on the pipeline between the indoor condenser 3 and the indoor evaporator 10, the indoor condenser 3 and the outdoor heat exchanger The parallel first valve 5 between 6, the second three-way valve 8 arranged between the outdoor heat exchanger 6 and the indoor evaporator 10, and the second three-way valve 8 arranged between the inlet of the indoor evaporator 10 The first throttling device 9; the bypass of the second three-way valve 8 is connected to the pipeline before the inlet of the compressor 1 and the indoor evaporator 10.

[0033] A first three-way valve 2 is arranged on the pipeline between the compresso...

Embodiment 2

[0049] Embodiment 2 is to use a three-way valve to control the opening and closing of the refrigerant channel of the indoor condenser in Example 1, and instead use a damper to control the opening and closing of the air channel of the indoor condenser, as Figure 5 shown.

[0050] In the cooling mode, adjust the air valve 36 to state a, close the air duct flowing through the indoor condenser, open the bypass air duct of the indoor condenser, open the first valve 5, adjust the first three-way valve 8 to open the first throttling device 9 and Indoor evaporator 10 access, close its bypass branch, all the other parts are the same as embodiment 1. The indoor (inside the car) return air and the outdoor (outside the car) fresh air are regulated by the air valve 34 and then enter the air duct 31. After being cooled by the indoor evaporator 10 under the action of the fan 35, they are sent into the room through the air duct b, and the indoor is condensed The device 3 is blocked by the a...

Embodiment 3

[0053] like Image 6 As shown, an electric vehicle air conditioning system using air source heat pump, the system uses low temperature air source air conditioning heat pump technology to realize the conversion of three modes of cooling, conventional heating and low temperature heating;

[0054] The electric vehicle air conditioning system includes: a compressor 1, a first three-way valve 2, an indoor condenser 3, a first valve 5, an outdoor heat exchanger 6, a second three-way valve 8, and a first throttling device 9 , an indoor evaporator 10 and a gas-liquid separator 11; the system also includes a flash separator 25, a fourth throttling device 14, a fourth valve 15, a third valve 24, a fifth throttling device 26 and a one-way valve 23; The flash separator and compressor 1 are connected through a return gas pipeline; the difference between it and Embodiment 1 is that the heating and low-temperature heating modes are different:

[0055] In normal heating mode, the first valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com