Method for evaluating corrosion of DC stray current on high strength steel for oil gas pipeline under stress condition

A technology for oil and gas pipelines and stray currents, applied in weather resistance/light resistance/corrosion resistance, material inspection products, measuring devices, etc., which can solve unscientific evaluation results, failure to consider the influence of pipeline stress in service, and inability to predict corrosion rates, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

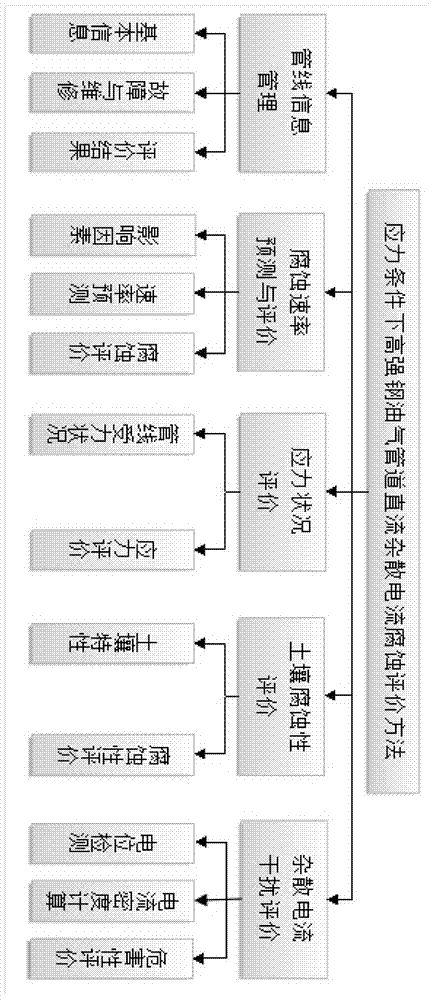

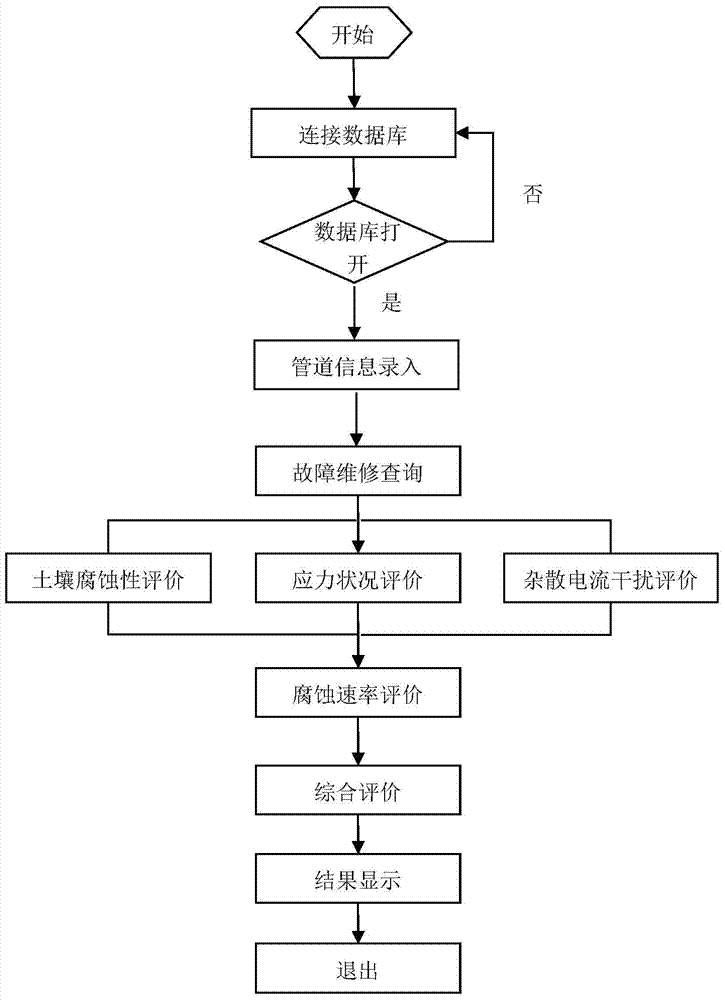

[0082] Such as Figure 1.1-6 As shown, a method for evaluating DC stray current corrosion of high-strength steel for oil and gas pipelines under stress conditions, the implementation steps of the method are as follows,

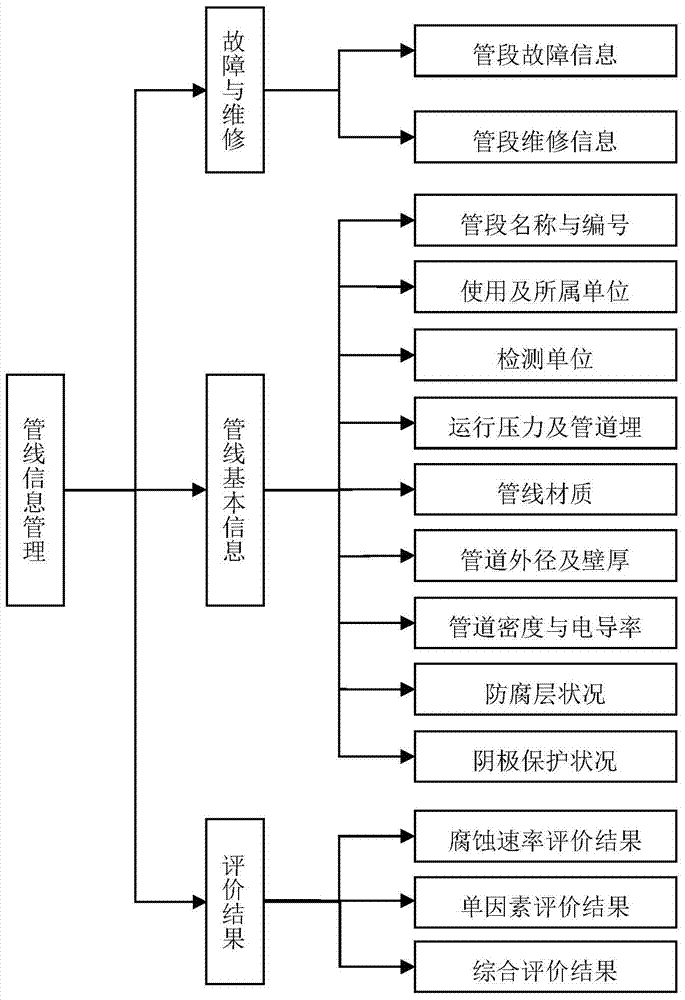

[0083] S1 pipeline information management

[0084] Figure 1.1 It shows the structural relationship diagram of the DC stray current corrosion evaluation method for high-strength steel oil and gas pipelines under stress conditions. The method work flow chart Figure 1.2 shown. Pipeline information includes three parts: basic pipeline information, pipeline fault and maintenance information, and pipeline evaluation results. Basic information management can input, modify and delete the basic information, failure and maintenance records of pipelines, and can also output the final evaluation results of pipelines. Pipeline infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com