Electromagnetic ultrasonic surface wave transducer and design method thereof

A technology of electromagnetic ultrasonic and design method, which is applied in the generation of ultrasonic/sonic/infrasonic waves and the analysis of solids using sonic/ultrasonic/infrasonic waves, etc. The effect of improving the efficiency and the amplitude of the surface wave signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

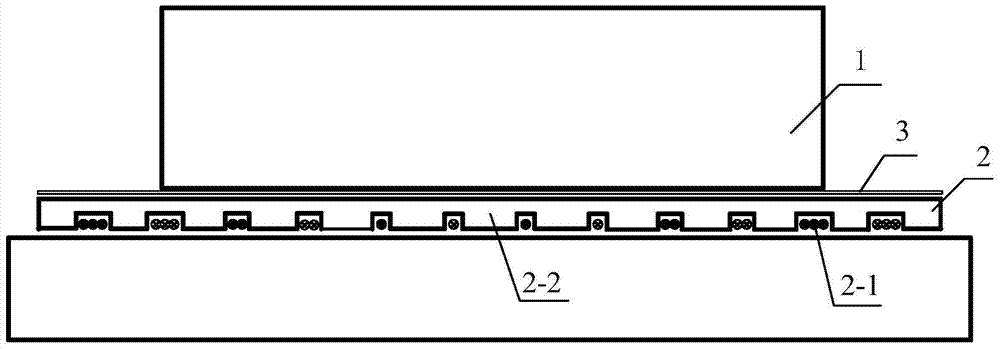

[0033] Specific implementation mode one: refer to figure 1 Specifically explain this embodiment, an electromagnetic ultrasonic surface wave transducer described in this embodiment, which includes: a magnet 1, a meander coil 2 and a copper foil 3;

[0034] The meander coil 2 includes: a wire 2-1 and a skeleton 2-2, and the number of turns of the meander coil 2 is n, wherein n=5,6,7;

[0035] The skeleton 2-2 is a left-right symmetrical structure, and 2n wire slots are arranged along one side of the skeleton 2-2, and each wire slot is provided with a wire 2-1 zigzag arranged in the shape of a square wave, so as to Two adjacent wire grooves are one level, and the number of wires in the n wire grooves gradually decreases from the two ends of the meandering coil 2 to the center of the skeleton 2-2;

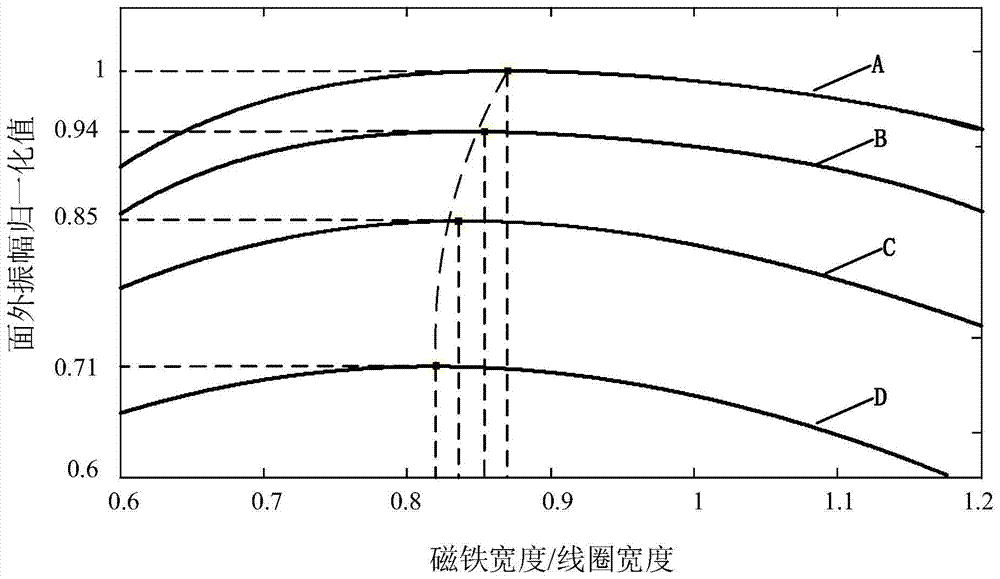

[0036] The lengths of the permanent magnet 1, the meandering coil 2 and the copper foil 3 are all equal, the widths of the meandering coil 2 and the copper foil 3 are equal, and the w...

specific Embodiment approach 2

[0042] Embodiment 2: This embodiment is a further description of the electromagnetic ultrasonic surface wave transducer described in Embodiment 1. In this embodiment, the wire 2-1 is an enameled wire wire.

specific Embodiment approach 3

[0043] Embodiment 3: This embodiment is a further description of the electromagnetic ultrasonic surface wave transducer described in Embodiment 1. In this embodiment, the thickness of the copper foil 3 is 0.1 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com