System for automatically detecting electronic products through two-dimension codes and method thereof

An electronic product, automatic detection technology, applied in the direction of electromagnetic radiation induction, etc., can solve the problems of low detection efficiency, slow information acquisition, low amount of acquired information, etc., to reduce the detection error rate, fast information acquisition, and improve detection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

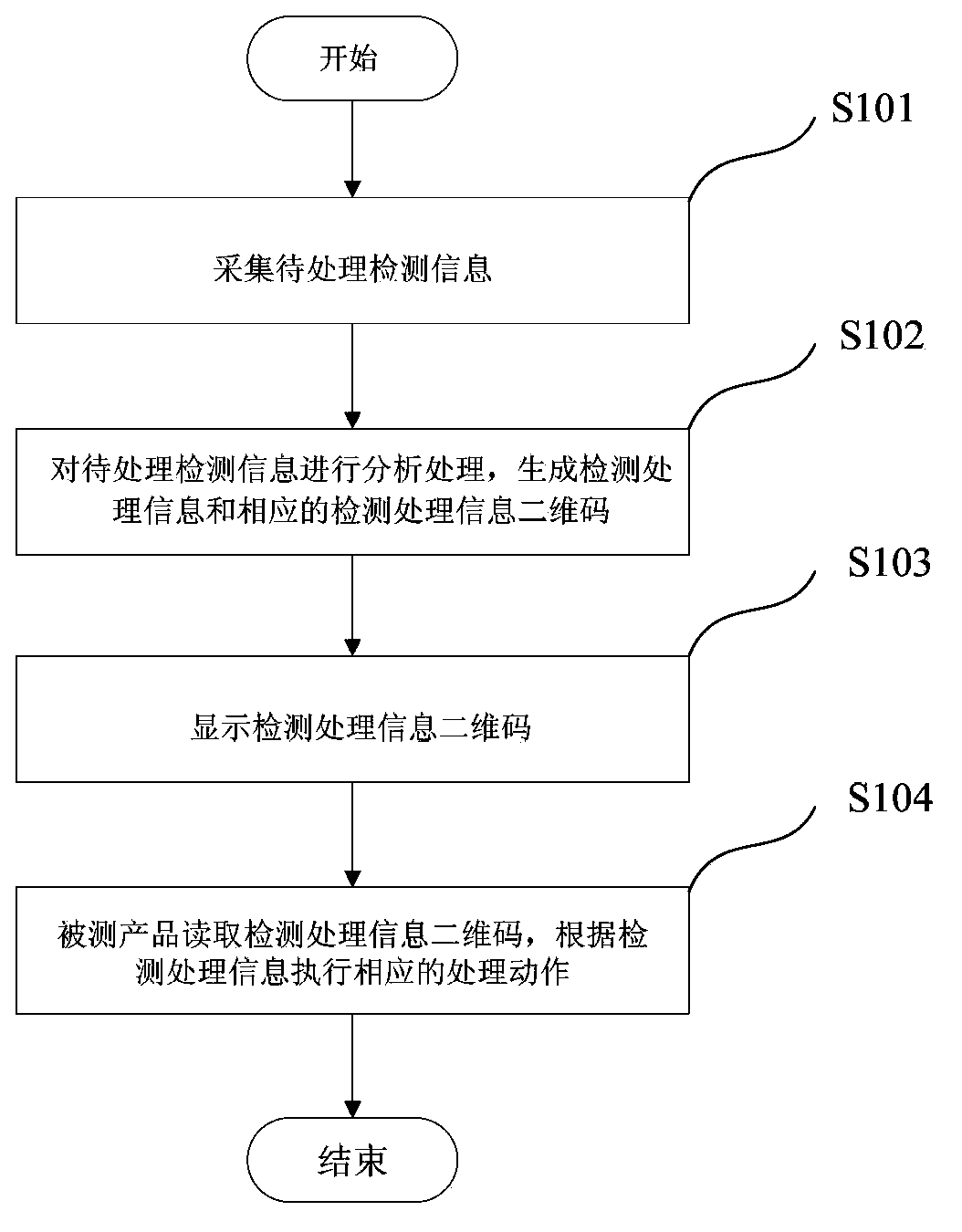

Method used

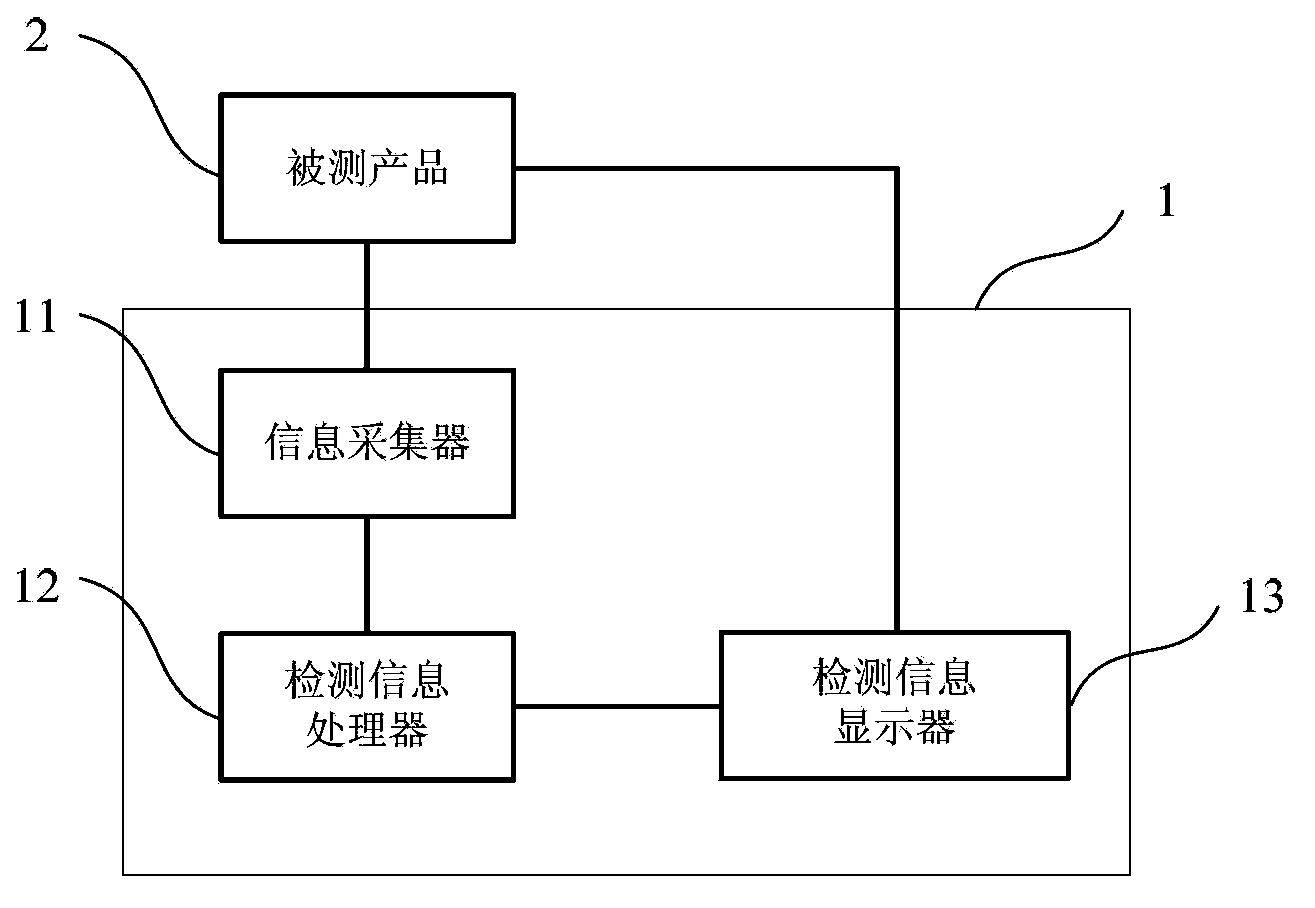

Image

Examples

Embodiment 1

[0039] At the serial number automatic detection station on the assembly line, the barcode scanner and the camera are fixed on the fixed frame of the assembly line, and the serial number information of the product under test is printed on the process card in the form of a bar code, and the process card is accompanied by the product under test 2 Flowing on the assembly line, when flowing through the barcode scanner, the scanning end of the barcode scanner automatically scans the barcode on the collection process card, and sends the serial number information of the process card in the barcode to the detection device connected to the wired end of the barcode scanner In the information processor 12.

[0040] The detection information processor 12 receives the process card serial number information, processes it into process card serial number acquisition information, and displays the process card serial number acquisition information in the form of a two-dimensional code to the test...

Embodiment 2

[0043] The display screen of the product under test 2 displays a two-dimensional code of the serial number information of the product under test. At the serial number automatic detection station on the assembly line, when the process card and the product under test 2 flow through the barcode scanner, the barcode scanner automatically scans and collects the barcode of the process card serial number information on the process card, and the camera is aligned with the display of the product under test 2 screen to collect the serial number information of the product under test, or collect the serial number information of the process card and the serial number information of the product under test through the camera.

[0044] The detection information processor 12 receives the process card serial number information and the self-serial number information of the tested product, generates serial number comparison pass / fail information after analyzing and comparing, and compares the seri...

Embodiment 3

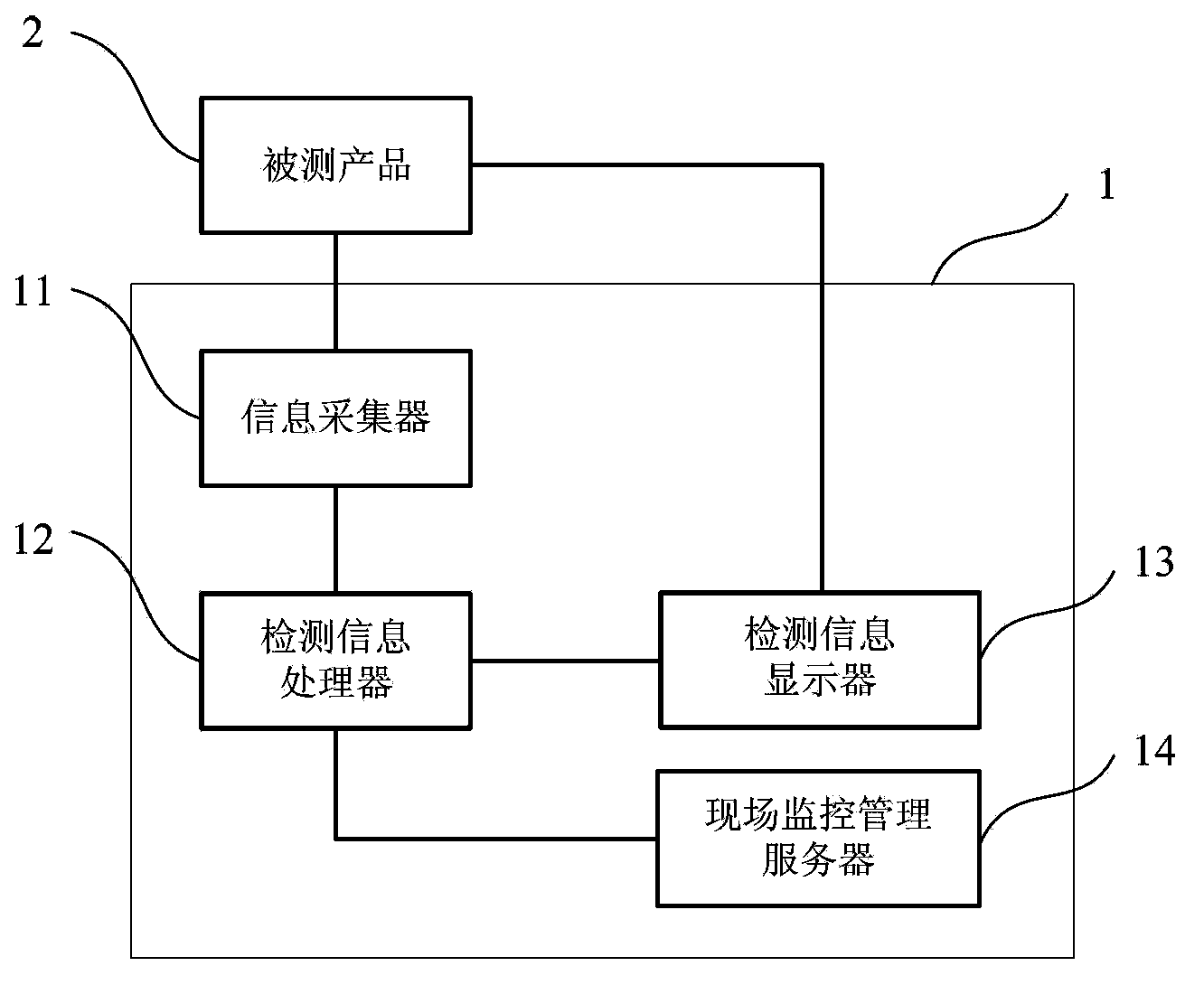

[0049] In order to facilitate the recording and tracking of the production process of all products, the production enterprise will also transmit the relevant information and test results of the tested product 2 to the on-site monitoring and management system.

[0050] see figure 2 , which is another schematic structural diagram of the system for automatic detection of electronic products using two-dimensional codes according to the present invention. Such as figure 2 As shown, the system 1 for automatic inspection of electronic products using two-dimensional codes also includes an on-site monitoring and management server 14 for receiving and recording inspection and processing information.

[0051] Detect the display screen of the product under test 2. At the display screen automatic detection station on the assembly line, when the process card and the product under test 2 flow through the barcode scanner and camera on the assembly line, the barcode scanner collects the ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com