Sapphire screen cover glass and manufacturing method thereof

A technology of sapphire and cover glass, which is applied in the direction of electromagnetic radiation induction, etc., which can solve the problems of loss, high production cost, and high cost of sapphire single chip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

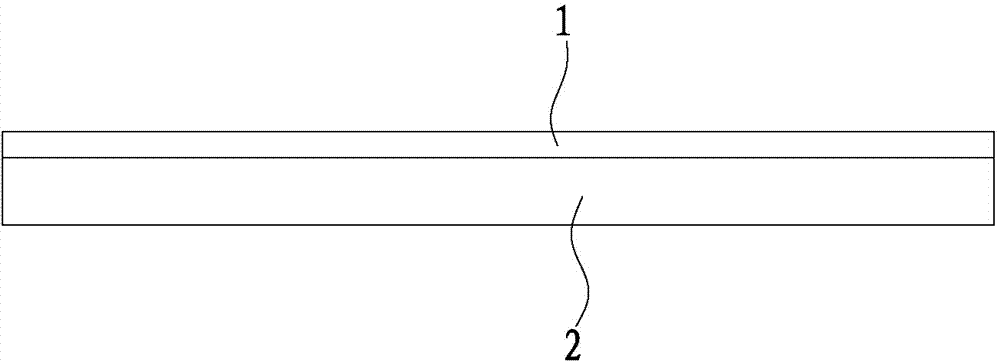

[0019] Such as figure 1 As shown, a sapphire screen cover glass disclosed by the present invention is composed of a sapphire ultra-thin sheet 1 and a soft material 2. Sapphire ultra-thin flakes are 50-200 microns thick. The soft material is resin film, polycarbonate or acrylic, and the thickness of the soft material is 0.1-0.3 mm. The ultra-thin sapphire sheet 1 is attached to the soft material 2 .

[0020] During the specific processing, the sapphire single crystal block that has been positioned and carried out the intelligent stripping process (existing technology) is polished on one side. The polishing requirements are surface roughness Ra<0.2nm and flatness less than 5μm; intelligent stripping technology smart- cut, choose appropriate ions (such as H hydrogen) to carry out high-dose ion implantation of sapphire single crystal that has been positioned and cut, use the implantation energy to control the expected cut thickness, separate the slices after heat treatment, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com