Cooling device of high-power solid laser

A technology of solid-state lasers and cooling devices, applied in the field of lasers, can solve problems such as water leakage, large volume, and complicated pipelines, and achieve the effects of improving temperature uniformity, accelerating heat transfer, and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

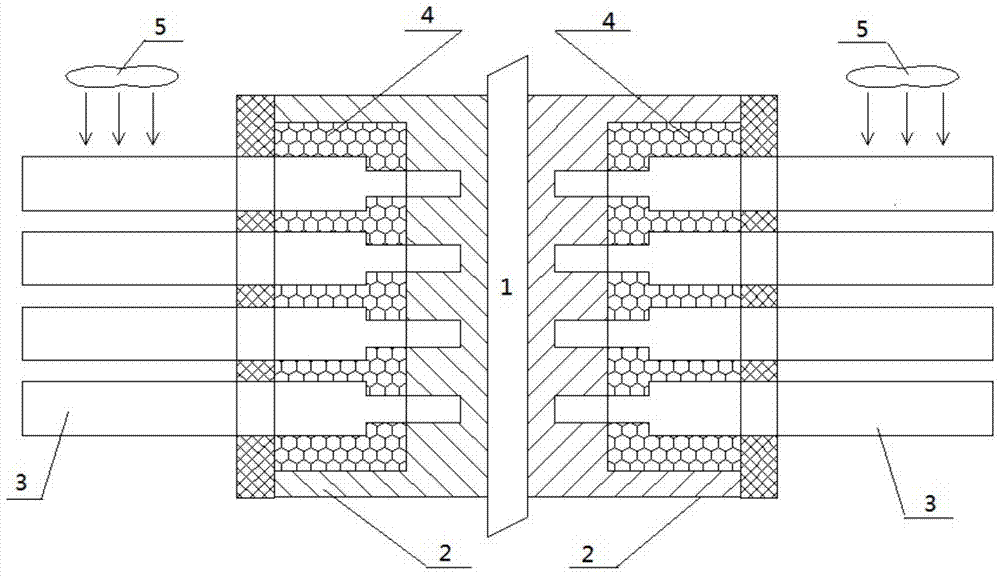

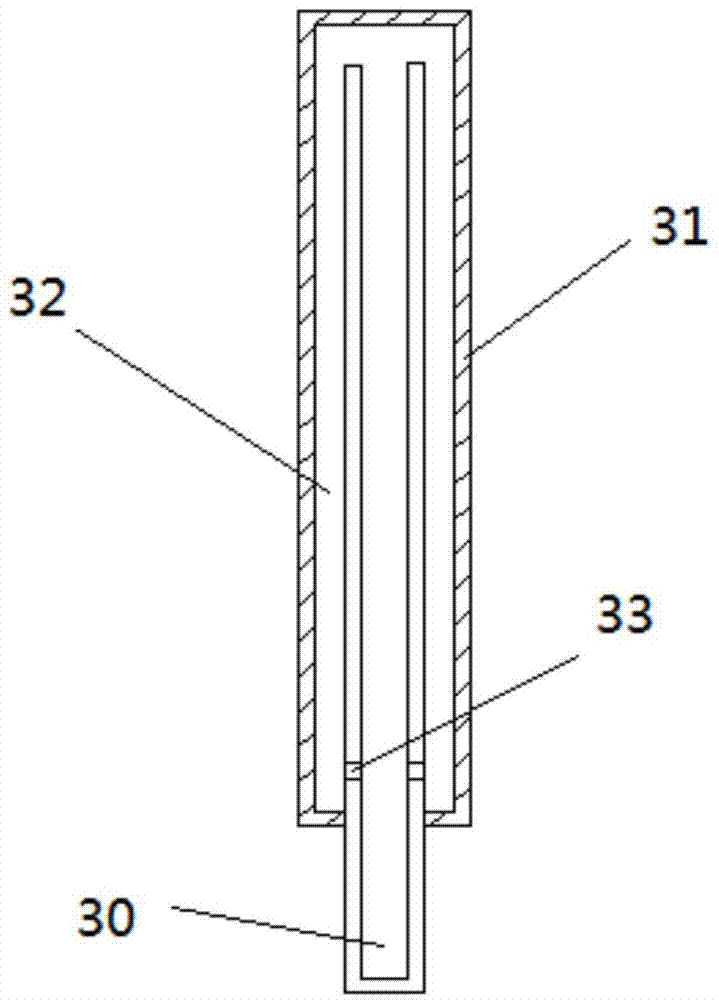

[0028] In the first embodiment of the present invention, a cooling device for a solid-state laser, such as figure 1 As shown, it includes the following components: a heat sink 2, a split heat pipe 3, a phase change microcapsule plate 4 and a cooling fan 5, wherein the heat sink 2 can be a copper heat sink. One side of the heat sink 2 is in close contact with the gain medium 1 of the high-power solid-state laser through low-contact thermal-resistance welding, and the low-contact thermal-resistance welding may be indium evaporation or the like.

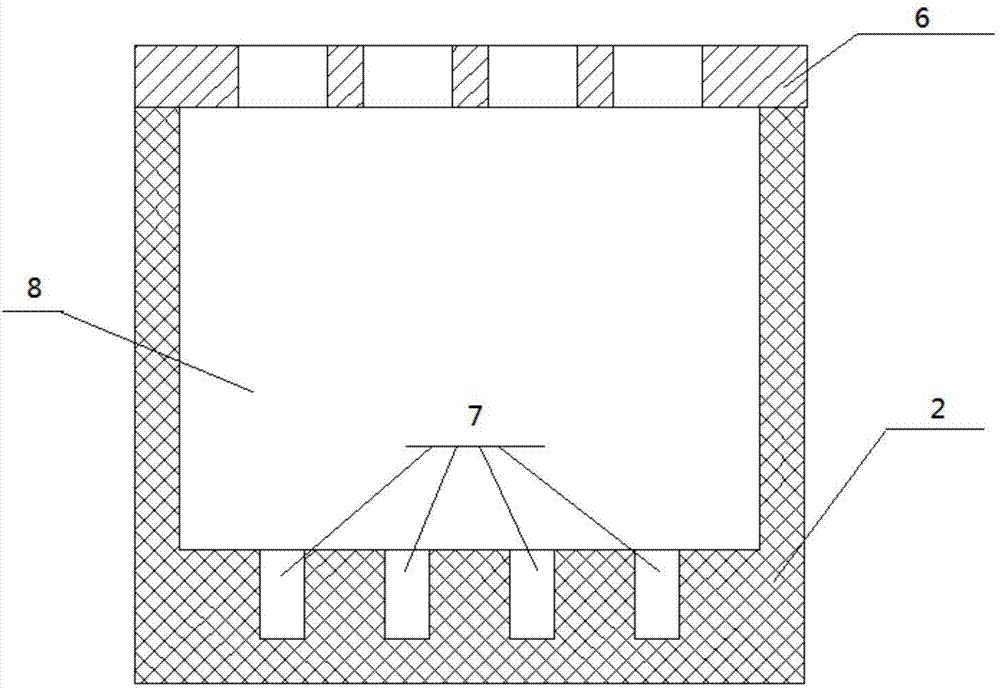

[0029] Such as figure 2 As shown, the other side of the heat sink 2 is provided with an end cover 6 , a groove 7 conforming to the shape of the evaporation section of the split heat pipe 3 , and a cavity 8 for matching the phase change microcapsule plate. The end cap 6 is used to fix the split heat pipe 3 and prevent the liquid from overflowing from the heat sink due to the rupture of the phase change microcapsules.

[0030] The phas...

no. 2 example

[0040] The second embodiment of the present invention is a heat dissipation device for a high-power solid-state laser. The heat dissipation device of this embodiment is substantially the same as that of the first embodiment, the only difference being that the heat dissipation device of this embodiment includes the following components: Heat sink, shunt heat pipe and cooling fan without phase change microcapsule plate.

[0041] Among them, one side of the heat sink is in close contact with the gain medium of the high-power solid-state laser, and the other side of the heat sink is provided with a groove that matches the shape of the evaporation section of the split heat pipe;

[0042] When the split heat pipe is inserted into the groove of the heat sink, the condensation section of the split heat pipe is located in the air, and the heat dissipation of the condensation section is accelerated by the cooling fan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com