Bar wound stator winding layout with long-pitched and short-pitched coils

A long-pitch, short-pitch technology, applied in the field of stator components, can solve the problem of lack of conductor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

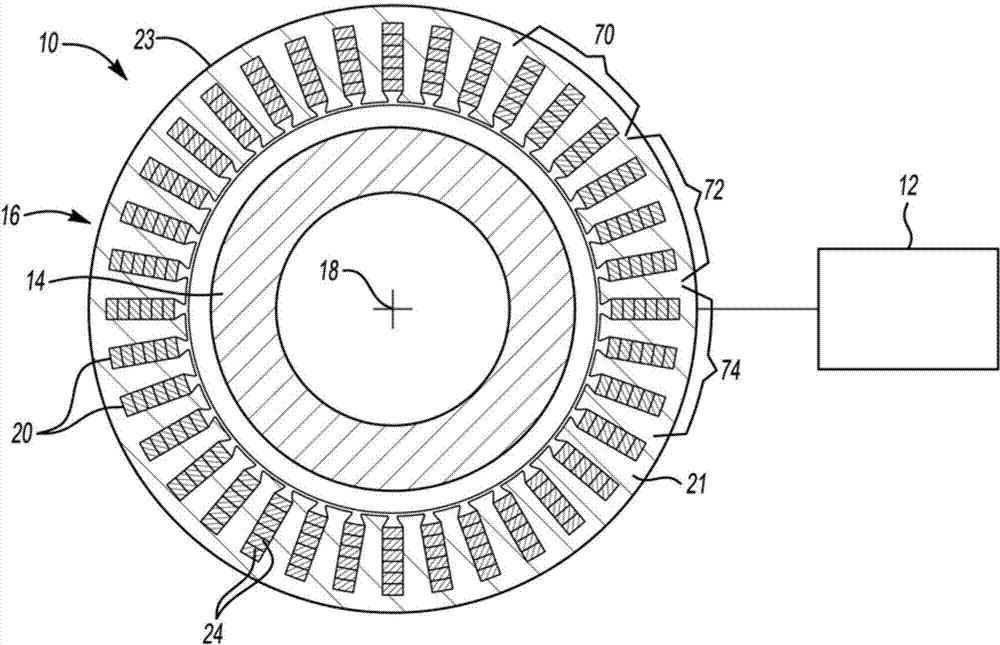

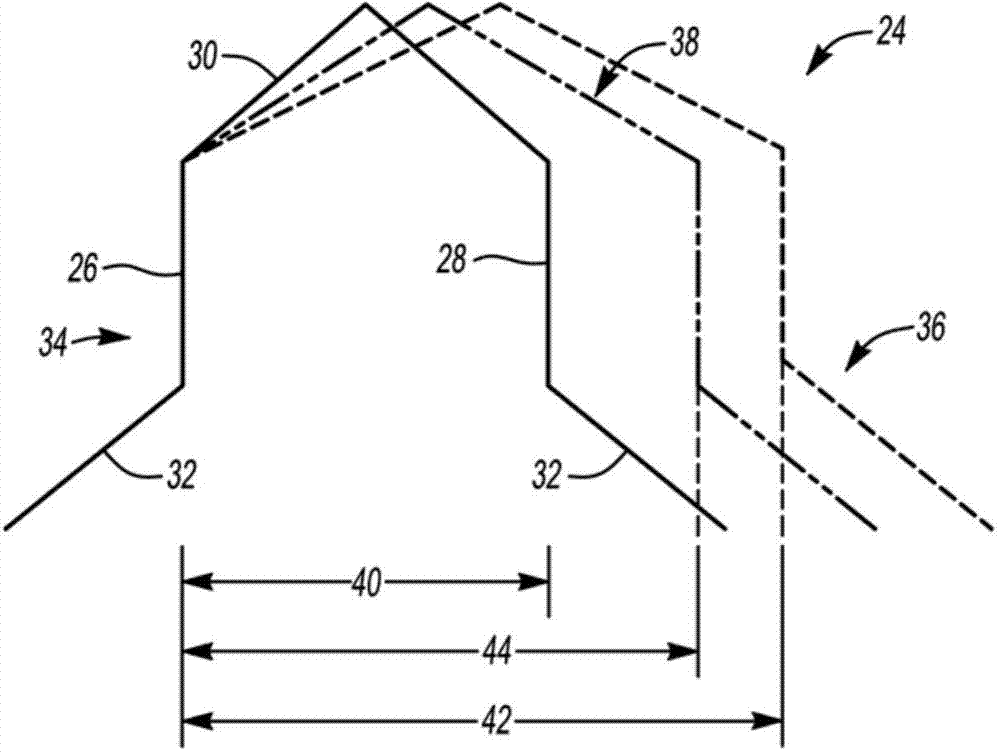

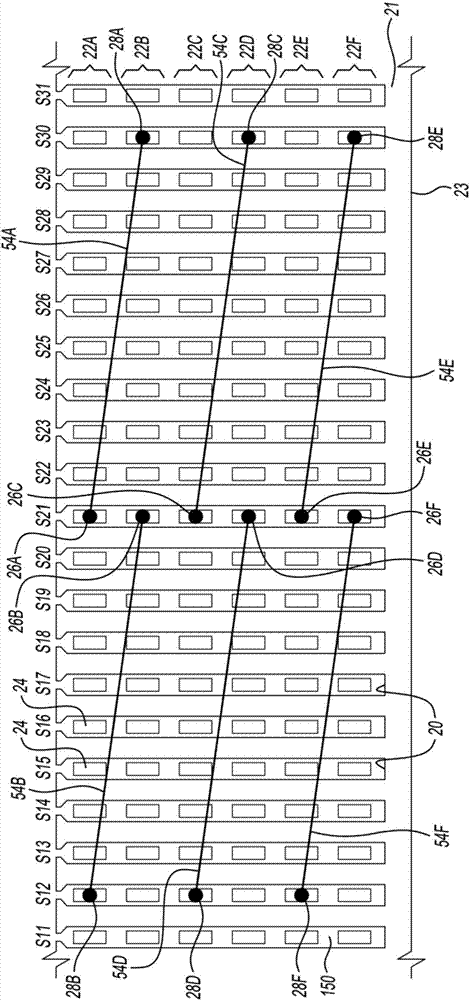

[0016] Referring to the drawings, in which like reference numerals refer to like or similar components throughout the several views, figure 1 is a schematic partial cross-sectional view of an electric motor / generator or electric traction machine, referred to herein as electric machine 10 . The electric machine 10 may be used in a vehicle 12 . Vehicle 12 may be any passenger or commercial vehicle, such as a hybrid electric vehicle, including a plug-in hybrid electric vehicle, an extended-range electric vehicle, or other vehicles. Electric machine 10 may include any device configured to generate electric machine torque, for example, by converting electrical energy into rotational motion. For example, electric machine 10 may be configured to receive electrical power from a power source, such as a battery array (not shown). The power supply can be configured to store and output electrical energy. The vehicle 12 may include an inverter (not shown) for converting the DC voltage f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com