Manufacturing method for rolling plate hollow roller, rolling plate hollow roller and steel sheet manufacturing technology device

A manufacturing method and a coiling technology, which are applied in the manufacture of coiled hollow drums, coiled hollow drums, and steel plate manufacturing process devices, and can solve problems such as inability to fully utilize equipment production capacity, steel plate meandering or slipping, and unqualified products , to achieve the effect of easy application of laser welding, ensuring butt joint accuracy and shortening construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment >

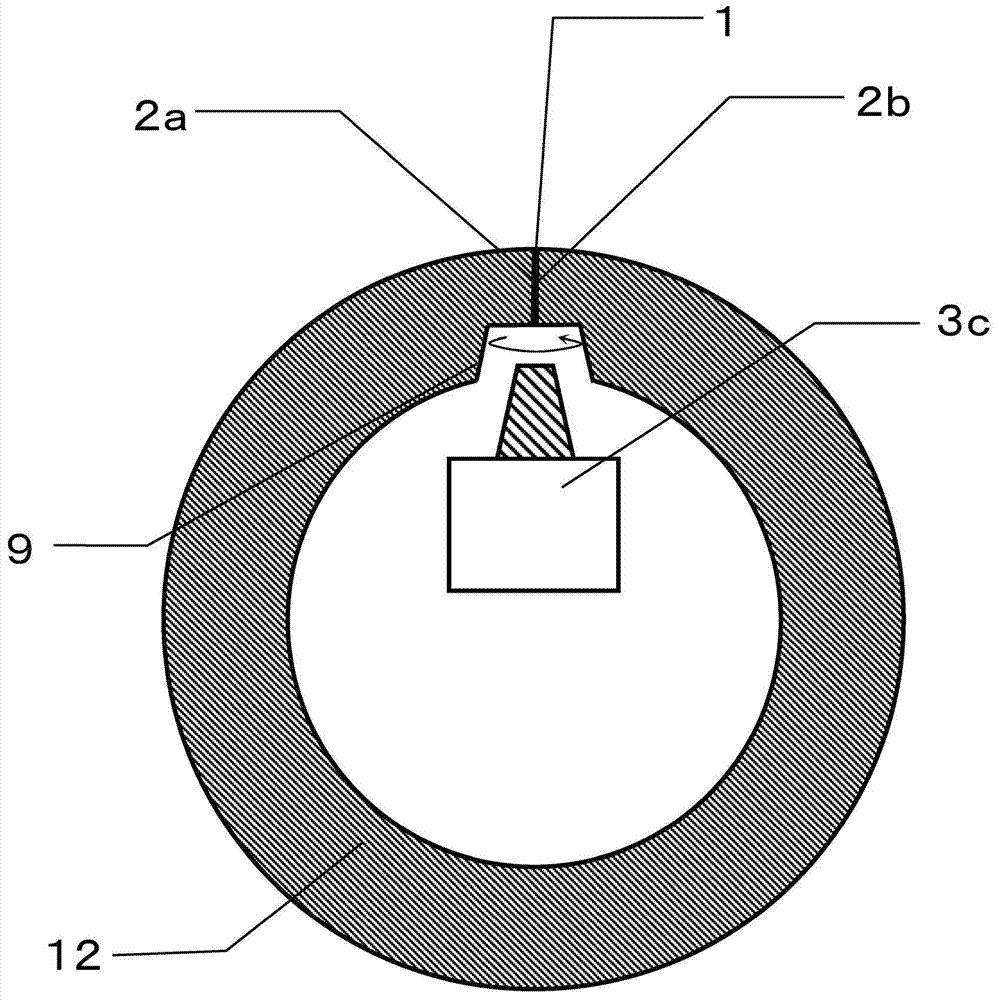

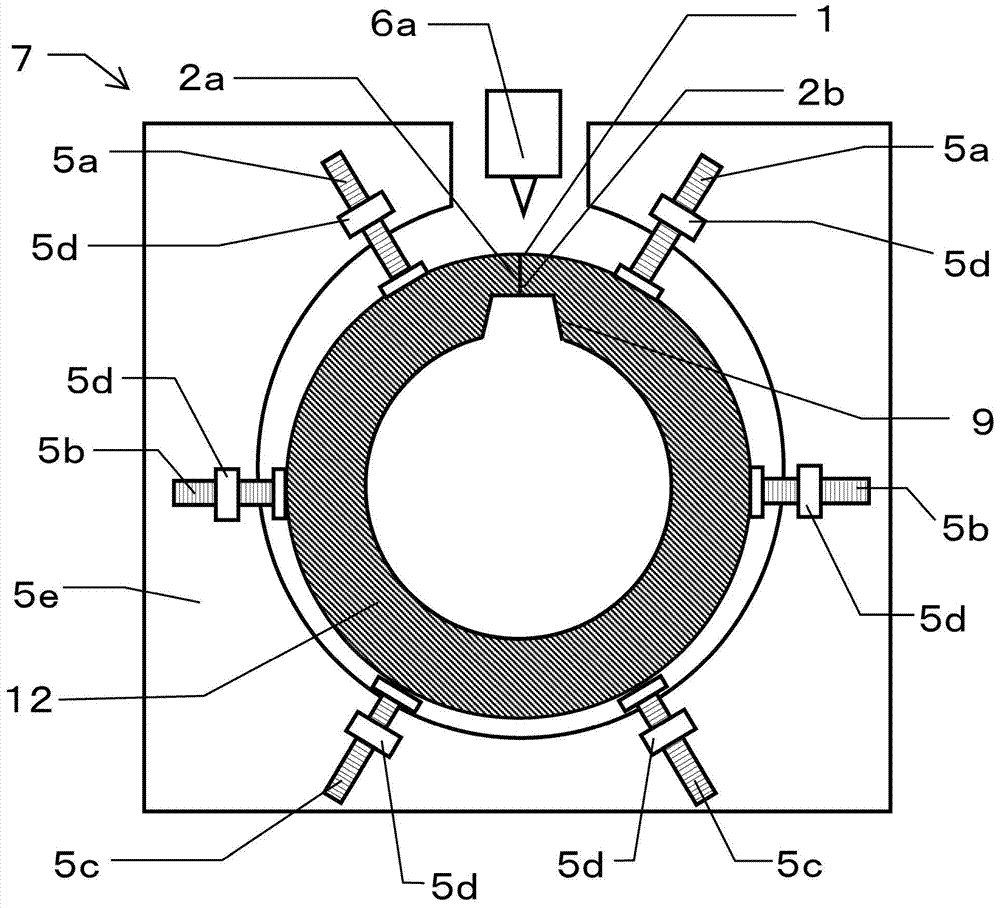

[0064] use Figure 1 to Figure 5 The first embodiment of the manufacturing method of the board bending hollow roll of this invention is demonstrated.

[0065] First, coiling is performed by bending a rectangular metal plate into a cylindrical shape.

[0066] As the metal plate, other than carbon steel, stainless steel, chromium steel enhanced in hardenability or wear resistance, or chrome-molybdenum steel can be used.

[0067] In addition, the method of coiling processing should just be a well-known method.

[0068] Next, the butt left end surface 2a and the butt right end surface 2b of the cylindrical metal plate 12 subjected to the coiling process are spot-welded to the butt portion 1 of the metal plate 12, preferably to the side of the butt portion 1. Welding is temporarily fixed so that it becomes a butt joint state.

[0069] Then, if figure 1 As shown, the inner peripheral surfaces of the butt left end surface 2a and the butt right end surface 2b after temporarily fix...

no. 2 Embodiment >

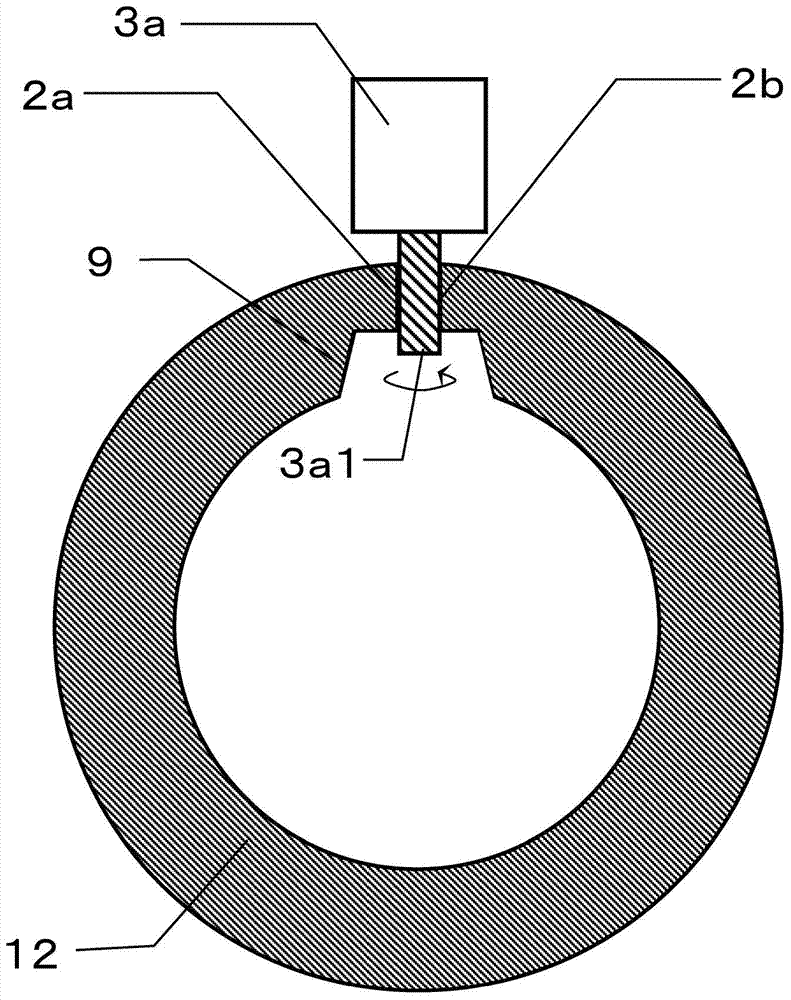

[0107] use Figure 6 and Figure 7 The second embodiment of the manufacturing method of the board bending hollow roll of this invention is demonstrated.

[0108] First, in the same manner as in Example 1, a plate bending process of bending a rectangular metal plate into a cylindrical shape was performed. Then, spot welding or the like is performed on the butt portion 1 of the cylindrical metal plate 12 , preferably on the side surface of the butt portion 1 , to temporarily fix and weld it, thereby bringing it into a butt state.

[0109] Next, if figure 1 As shown, beveling is performed on the inner peripheral surface side of the butt part 1 after provisional fixing welding by a machining device 3 c having an end mill or the like.

[0110] Then, use Figure 6 A machining device 3b having a tapered end mill 3b1 as shown performs butting processing on the mating portion 1 of the metal plate 12 to form tapered gaps at intervals of about 10 mm.

[0111] Here, for example as ...

no. 3 Embodiment >

[0124] use Figure 8 The third embodiment of the manufacturing method of the board bending hollow roll of this invention is demonstrated.

[0125] Figure 8 It is an explanatory diagram of the laser welding process performed by an arm robot.

[0126] First, in the same manner as in Example 1 and the like, a plate bending process of bending a rectangular metal plate into a cylindrical shape was performed. Then, spot welding or the like is performed on the butt portion 1 of the cylindrical metal plate 12 , preferably on the side surface of the butt portion 1 , to temporarily fix and weld it, thereby bringing it into a butt state.

[0127] Next, if figure 1 As shown, beveling is performed on the inner peripheral surface side of the butt part 1 after provisional fixing welding by a machining device 3 c having an end mill or the like.

[0128] And, using a machining device having a linear end mill 3a1 or a tapered end mill 3b1, the mating portion 1 of the metal plate 12 is subj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com