Impinging stream gas purification system

A gas purification system, impinging flow technology, applied in air conditioning systems, chemical instruments and methods, heating methods, etc., can solve the problems of low efficiency, small processing capacity, inability to conduct deep and multi-wave gas-liquid contact, etc. The effect of eliminating membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

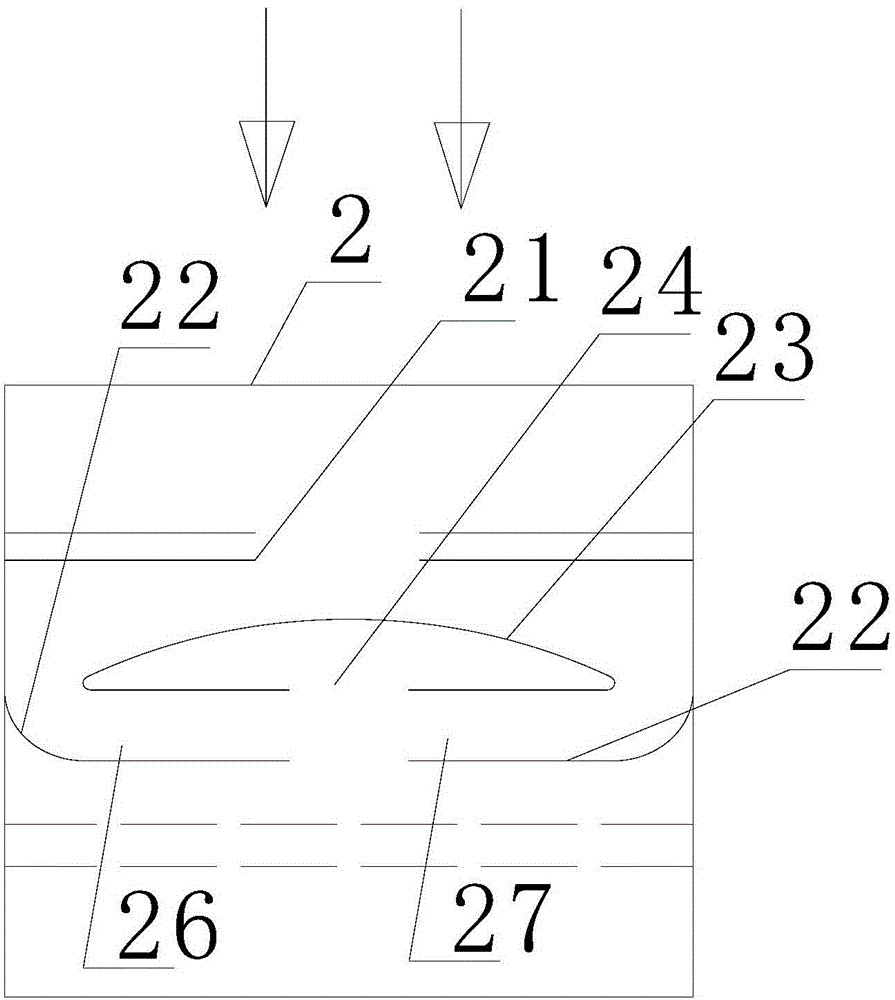

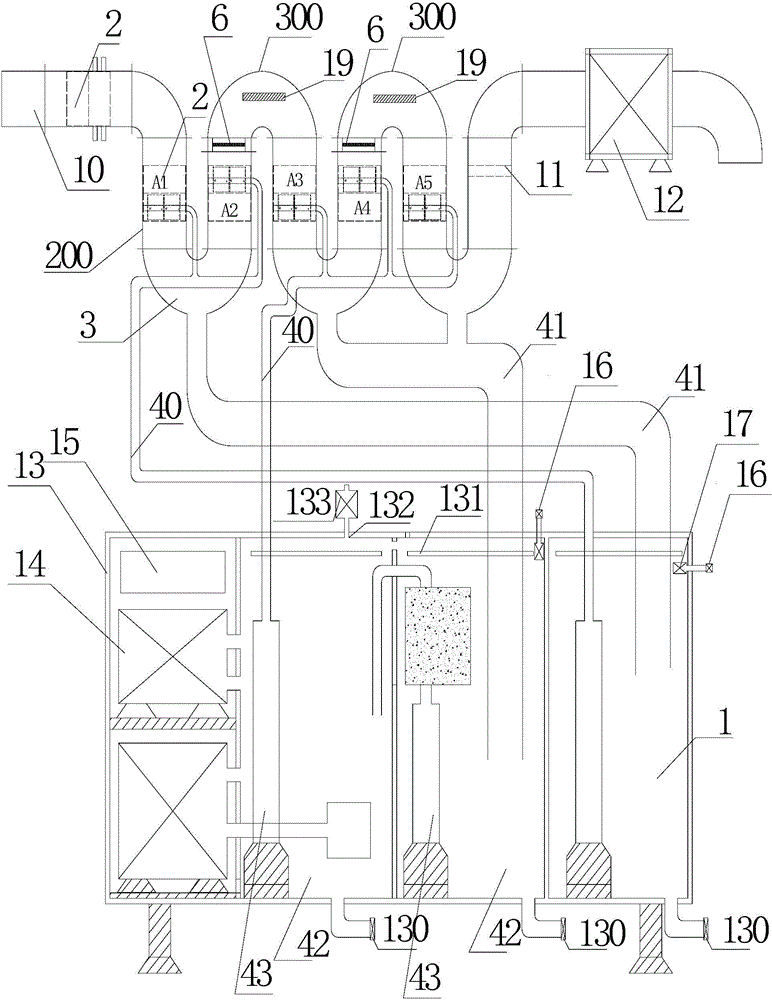

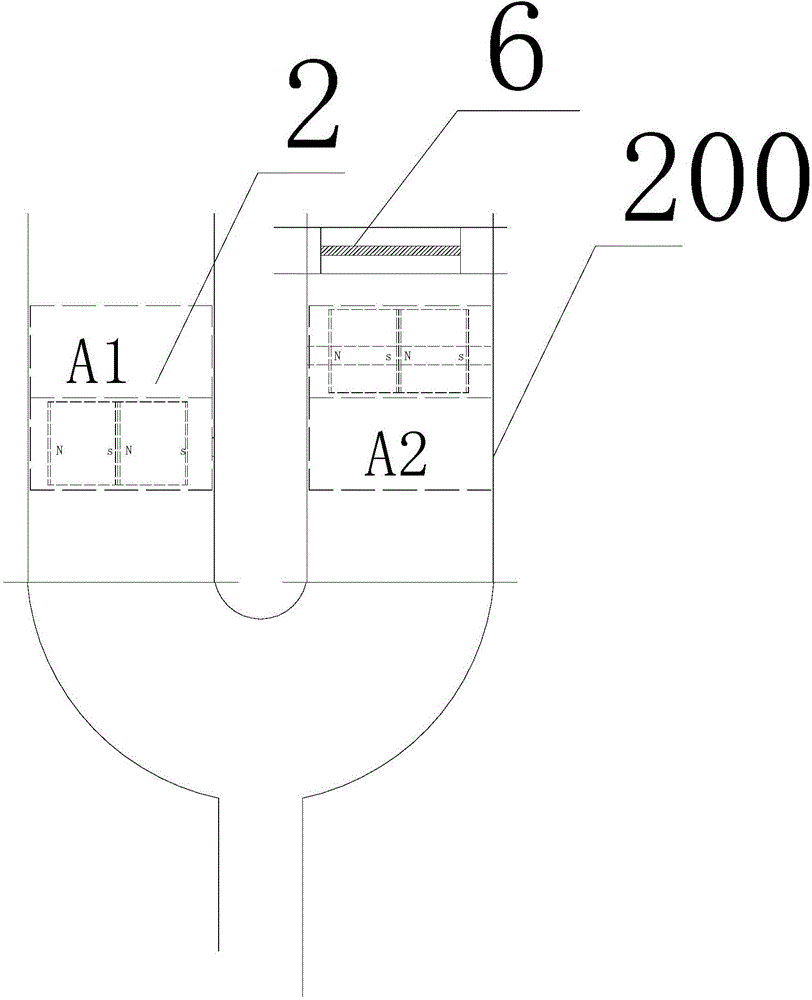

[0054] see figure 1 Embodiment 1 of the present invention provides an impinging flow gas purification system 1, which includes several purification unit devices 200 arranged at intervals in sequence, and two adjacent purification unit devices 200 are communicated through a first pipeline 300 (ie A plurality of purification unit devices 200 are sequentially connected through the first pipeline 300 in the same horizontal direction); each of the purification unit devices 200 includes an upright impingement flow type gas-liquid reaction chamber 2, an inverted impingement flow type gas-liquid reaction chamber Chamber 2 and the second connecting pipe 3 connecting the upright impinging flow gas-liquid reaction chamber 2 and the inverted impinging flow gas-liquid reaction chamber 2; wherein, the above-mentioned second connecting pipe 3 is actually a 180-degree turning angle A connecting pipe; the upright impinging flow gas-liquid reaction chamber 2 and the inverted impinging flow gas...

Embodiment 2

[0092] The specific structure of the impinging flow gas purification system provided by Embodiment 2 of the present invention is the same as Embodiment 1, but its layout is different. For details, please refer to Figure 8 , the impinging flow gas purification system shown in Embodiment 2, the distribution sequence and distribution position of each water tank can be determined according to the specific situation and the actual composition and purification requirements of the gas to be purified.

Embodiment 3

[0094] Such as Figure 9 As shown, the structure of the impinging flow gas purification system is also one of many variations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com