Method and system for dust disposal during ore processing

A technology for dust treatment and ore, applied in separation methods, chemical instruments and methods, cleaning methods and utensils, etc., to save labor costs, reduce equipment failure rates, and improve inspection quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

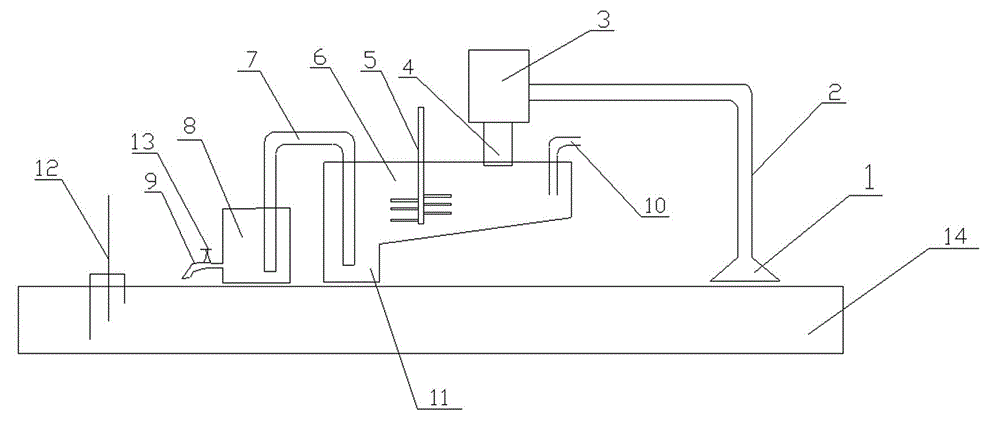

[0024] Such as figure 1 As shown, a dust processing system in ore processing includes a dust hood 1, which is connected to a dust collector 3 through a dust suction pipe 2, and the dust hood 1 absorbs dust and enters the dust collector 3 through the dust pipe 2 For dust removal, the dust collector 3 adopts a pulse bag filter, and the mud sedimentation tank 6 is dug on the ground near the dust collector 3. There is a mud collection well 11 in the mud sedimentation tank 6, and the unloading position of the dust collector 3 is changed to allow the dust to pass through the dust removal The ash unloading pipe 4 is directly discharged into the mud sedimentation tank 6. The mud agitator 5 and the water inlet pipe 10 are installed in the mud sedimentation tank 6, and water is added to the mud sedimentation tank 6 through the water inlet pipe 10, and then the mud is stirred by the mud mixer 5 to remove dust When the mortar reaches a proper consistency, a mud tank 8 is installed above the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com