Optical glass and optical element

A technology of optical glass and optical components, applied in the direction of optical components, optics, glass molding, etc., can solve the problems that cannot fully meet the requirements of optical design, achieve high transmittance, high dispersion, reduce unevenness and blur effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

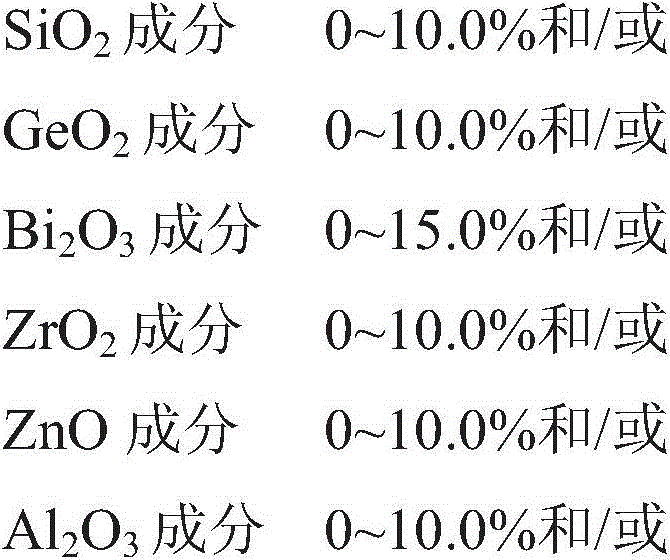

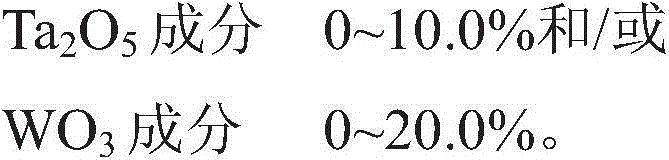

Method used

Image

Examples

Embodiment

[0102] Compositions (mass %) of Examples (No.1 to No.31) and Comparative Examples (No.1 to No.2) of the present invention, and Sb of these glasses 2 o 3 Concentrations of ingredients (relative to Sb 2 o 3 The mass % of the mass based on oxides other than the composition), the refractive index (n d ), Abbe number (v d ), and the wavelengths at which the spectral transmittance shows 70% and 5% (λ 70 , lambda 5 ) results are shown in Table 1 to Table 5. In addition, the following examples are for illustration only, and the present invention is not limited to these examples.

[0103] The test piece of the optical glass of the embodiment (No.1~No.31) of the present invention and the glass of comparative example (No.1~No.2) all adopts following method to make: select the oxide that is equivalent to each component, High-purity raw materials commonly used in optical glass such as hydroxides, carbonates, nitrates, fluorides, hydroxides, and methyl phosphoric acid compounds are u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com