Low-temperature sintered V series ZnO voltage-sensitive ceramic material and preparation method thereof

A varistor ceramic and low-temperature sintering technology, which is applied in the field of low-temperature sintered V-series ZnO varistor ceramic materials and its preparation, can solve the problems of high production cost, lower sintering temperature and potential gradient, and high potential gradient, and achieve low-voltage sensitive voltage, Reduced energy consumption and fewer types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

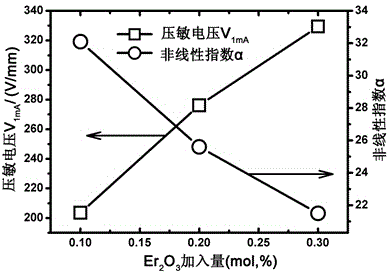

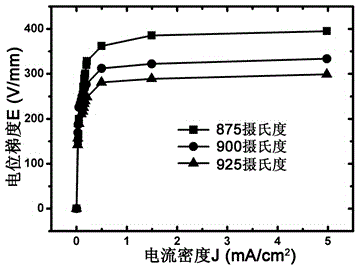

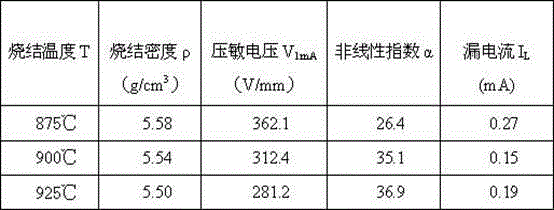

[0040] The low-temperature sintered V-based ZnO varistor ceramic material described in this embodiment is ZnO-V 2 o 5 As the matrix, the oxides of Mn, Nb, Gd, and Er are used as modifying additives.

[0041] The components and mole percentages of the V series ZnO varistor ceramic materials described in this embodiment are divided into: ZnO (97.5-x)mol%, V 2 o 5 1.2mol%, Mn 3 o 4 0.5mol%, Nb 2 o 5 0.5mol%, Gd 2 o 3 0.3mol%, Er 2 o 3 xmol% (x=0.1,0.2,0.3).

[0042] The preparation method of the low-temperature sintered V-system ZnO varistor ceramic material described in this embodiment specifically includes the following steps:

[0043] (1) Mix the powders of each component and carry out ball milling. The ball milling speed is 250r / min, and the ball milling time is 10h. Agate balls and absolute ethanol are selected as the ball milling medium, and the mass ratio of raw materials: agate balls: anhydrous ethanol is 1:10:3;

[0044] (2) Dry the ball-milled slurry at...

Embodiment 2

[0063] The low-temperature sintered V-based ZnO varistor ceramic material described in this embodiment is ZnO-V 2 o 5 As the matrix, the oxides of Mn, Nb, Gd, and Er are used as modifying additives.

[0064] The components and mole percentages of the V series ZnO varistor ceramic materials described in this example are divided into: ZnO 98.6mol%, V 2 o 5 0.5mol%, Mn 3 o 4 0.6mol%, Nb 2 o 5 0.1mol%, Gd 2 o 3 0.15mol%, Er 2 o 3 0.05mol%.

[0065] The preparation method of the low-temperature sintered V-system ZnO varistor ceramic material described in this embodiment specifically includes the following steps:

[0066] (1) Mix the powders of each component and carry out ball milling. The ball milling speed is 280r / min, and the ball milling time is 10h. Agate balls and absolute ethanol are used as the ball milling media. The mass ratio of raw materials: agate balls: absolute ethanol is 1:12:3.5;

[0067] (2) Dry the ball-milled slurry at 100°C for 20 hours to ...

Embodiment 3

[0087] The low-temperature sintered V-based ZnO varistor ceramic material described in this embodiment is ZnO-V 2 o 5 As the matrix, the oxides of Mn, Nb, Gd, and Er are used as modifying additives.

[0088] The components and mole percentages of the V series ZnO varistor ceramic materials described in this example are divided into: ZnO 97.8mol%, V 2 o 5 0.8mol%, Mn 3 o 4 1.0mol%, Nb 2 o 5 0.25mol%, Gd 2 o 3 0.125mol%, Er 2 o 3 0.025mol%.

[0089] The preparation method of the low-temperature sintered V-system ZnO varistor ceramic material described in this embodiment specifically includes the following steps:

[0090] (1) Mix the powders of each component and carry out ball milling. The ball milling speed is 260r / min, and the ball milling time is 10h. Agate balls and absolute ethanol are used as ball milling media. The mass ratio of raw materials: agate balls: anhydrous ethanol is 1:12.5:4;

[0091] (2) Dry the ball-milled slurry at 115°C for 16 hours to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Varistor voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com