One-step silicane cross-linked polyethylene cable material and preparation method thereof

A technology of cross-linked polyethylene and polyethylene, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problem of high investment costs, achieve the effect of not harsh process conditions, cost saving, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0015] A) Prepare the catalyst master batch, extrude and dry 20 parts of linear low density polyethylene, 80 parts of low density polyethylene, 2 parts of antioxidant, and 1 part of catalyst to obtain the catalyst master batch;

[0016] B) Put 50 parts of linear low-density polyethylene, 50 parts of low-density polyethylene, and 5 parts of catalyst masterbatch together in a closed mixer. , 0.04 parts of DCP initiator, 1 part of stearic acid, 0.2 parts of zeolite powder, etc. were added, and the materials were shaken in a closed mixer at a speed of 200r / min, discharged, and vacuum-packed to obtain one-step silane cross-linked polyethylene cables material.

example 2

[0018] A) preparing catalyst master batch, extruding and drying 50 parts of linear low density polyethylene, 50 parts of low density polyethylene, 2 parts of antioxidant, and 1 part of catalyst to obtain catalyst master batch;

[0019] B) Put 75 parts of linear low-density polyethylene, 20 parts of low-density polyethylene, and 5 parts of catalyst masterbatch in a closed mixer. , 0.02 parts of DCP initiator, 1.5 parts of stearic acid, 1 part of zeolite powder, etc. were added, and the materials were shaken in a closed mixer at a speed of 350r / min, discharged, and vacuum-packed to obtain one-step silane cross-linked polyethylene cables material.

example 3

[0021] A) Prepare the catalyst master batch, extrude and dry 80 parts of linear low density polyethylene, 20 parts of low density polyethylene, 2 parts of antioxidant, and 1 part of catalyst to obtain the catalyst master batch;

[0022] B) Put 80 parts of linear low-density polyethylene, 20 parts of low-density polyethylene, and 5 parts of catalyst masterbatch in a closed mixer. , 0.01 parts of DCP initiator, 2 parts of stearic acid, 2 parts of zeolite powder, etc. were added, and the materials were shaken in a closed mixer at a speed of 500r / min, discharged, and vacuum-packed to obtain one-step silane cross-linked polyethylene cables material.

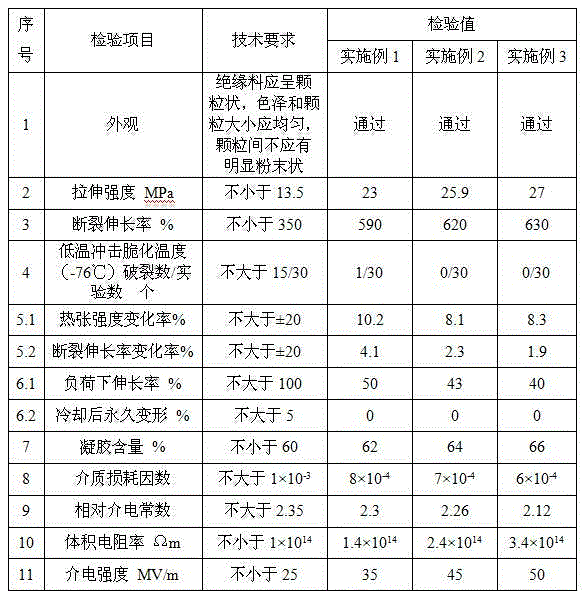

[0023] Test of properties of silane one-step cross-linked polyethylene cable material: Extrude the silane one-step cross-linked polyethylene material of the above-mentioned examples 1 to 3 of the present invention in a single-screw extruder, set the temperature of each zone to 175°C, and pull The speed is adjusted to 300r / min, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com