Outer ring forged piece of wheel hub unit

A technology for outer ring forgings and hub units, which is applied in the field of outer ring forgings, can solve the problems of no stable drilling positioning reference, low production efficiency of blank parts, and easy tilting of products, so as to save raw materials, save forging raw materials, and rational design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

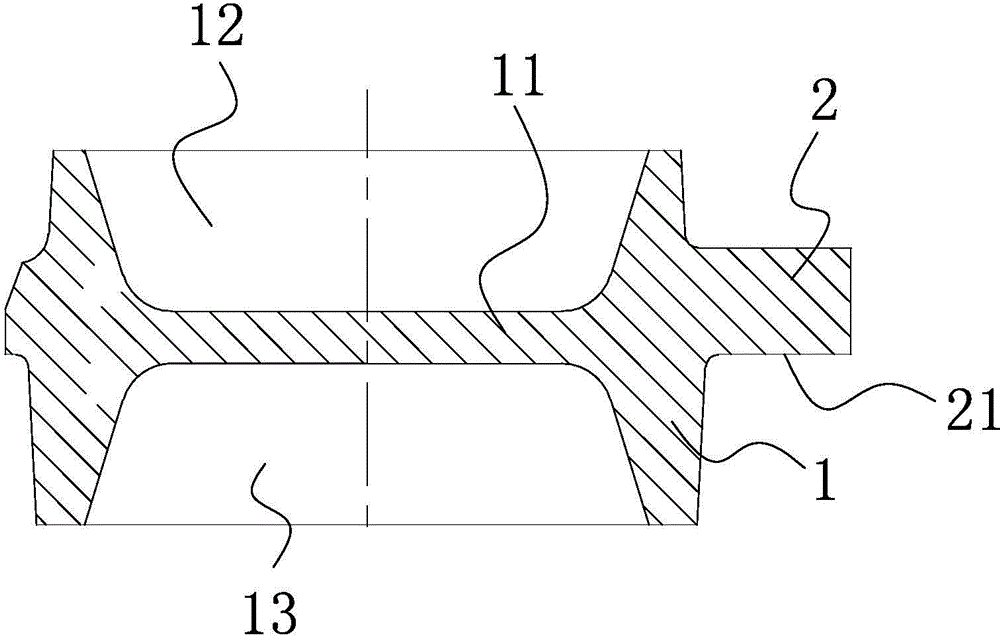

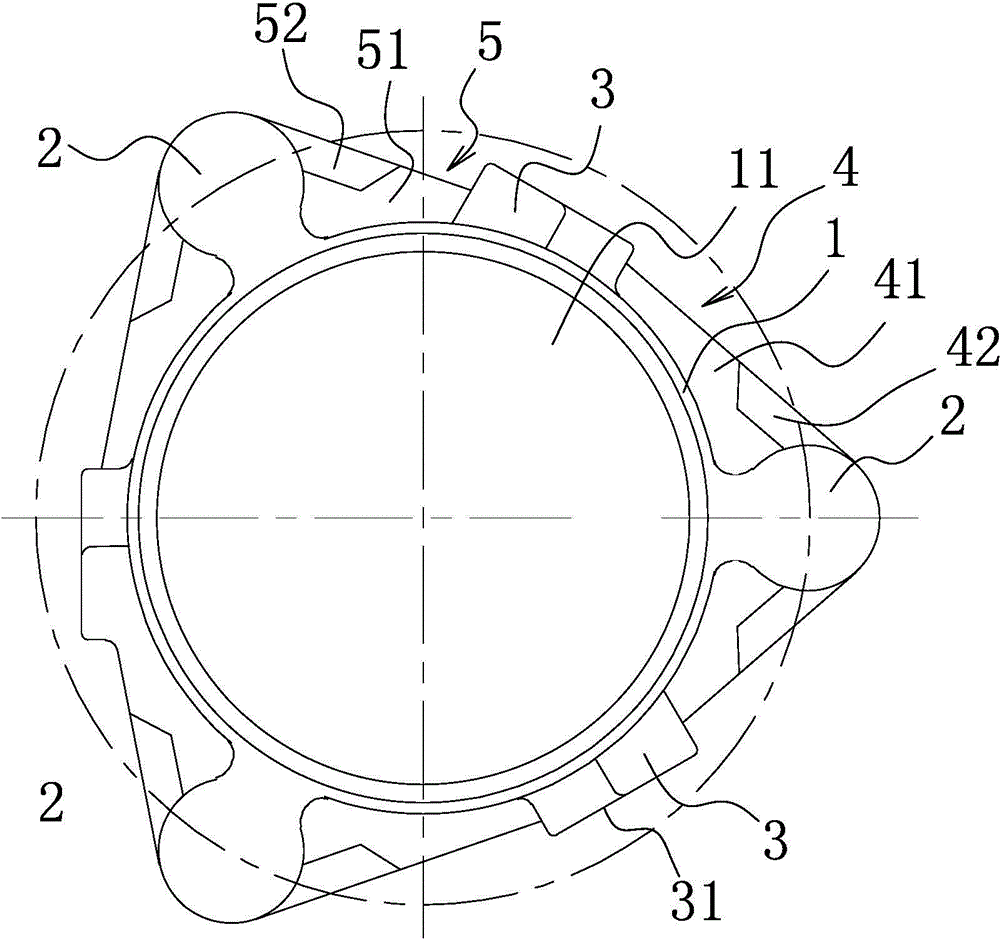

[0018] Such as Figure 1-2 As shown, the outer ring forging of the hub unit includes a cylindrical body 1, and the inner wall of the cylindrical body 1 is provided with a first tapered reserved blind hole 12 and a second tapered reserved blind hole. The reserved reinforcing part 11 of the blind hole 13, the optimization scheme, the axis line of the first tapered reserved blind hole 12 and the axis line of the second tapered reserved blind hole 13 are coincidently arranged, and on the outer wall of the cylindrical body 1 There are several columnar bodies 2 evenly distributed on the circumference, and the length of the columnar body 2 is less than the length of the cylindrical body 1. One end of each columnar body 2 is respectively provided with a reference positioning surface 21 and the reference positioning surface 21 is located at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com