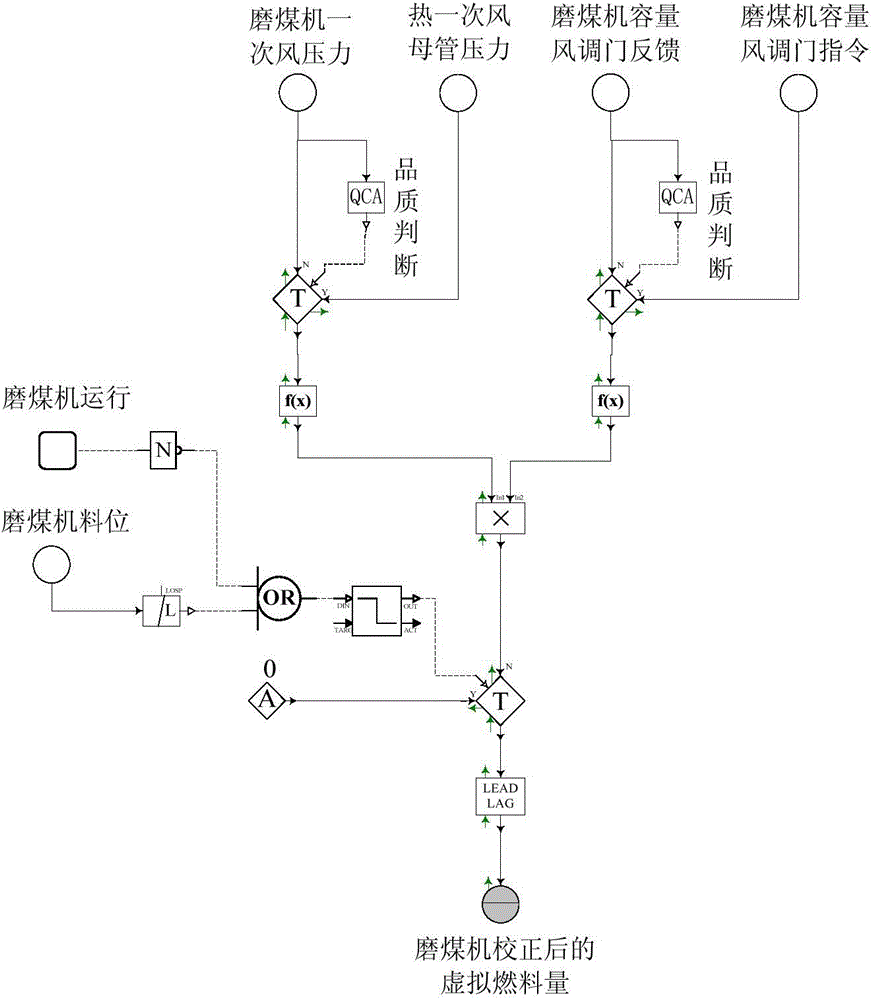

Method for controlling amount of coal conveyed into furnace of thermal generator set on basis of virtual fuel quantity

A control method and a technology of the amount of coal into the furnace, which is applied in the direction of combustion method, fuel supply adjustment, combustion control, etc., can solve the deviation of the amount of coal into the furnace, the large fluctuation of unit operating parameters, and the poor reliability of the coal mill capacity and air flow measurement, etc. problems, to achieve the effect of convenient configuration, improved stability and safety, and improved adjustment quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] (1) Calculation of fuel quantity command. ①Through the DCS analog input channel, the unit load command signal is obtained, and the unit load command is calculated by the fuel quantity command feedforward function to obtain the feedforward signal of the unit load to the fuel quantity. The corresponding relationship of the fuel quantity command feedforward function is shown in Table 1 The specific function form is determined according to the operating data of the unit. ②Take the measurement signal of the main steam pressure, and use conventional subtraction to subtract the main steam pressure from its set value to obtain the main steam pressure deviation signal; then, use the main steam pressure deviation signal to perform pressure deviation feedforward function calculation to form a pressure The corresponding relationship between the deviation feedforward signal and the pressure deviation feedforward function is shown in Table 2, and the specific function form is determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com