Coal-fired unit coordination control method and system

A coal-fired unit, coordinated control technology, applied in the direction of electric controllers, controllers with specific characteristics, etc., can solve the inability to guarantee the depth, speed, accuracy and quality requirements of load adjustment, poor coordination control adjustment quality, and anti-interference ability Weak and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

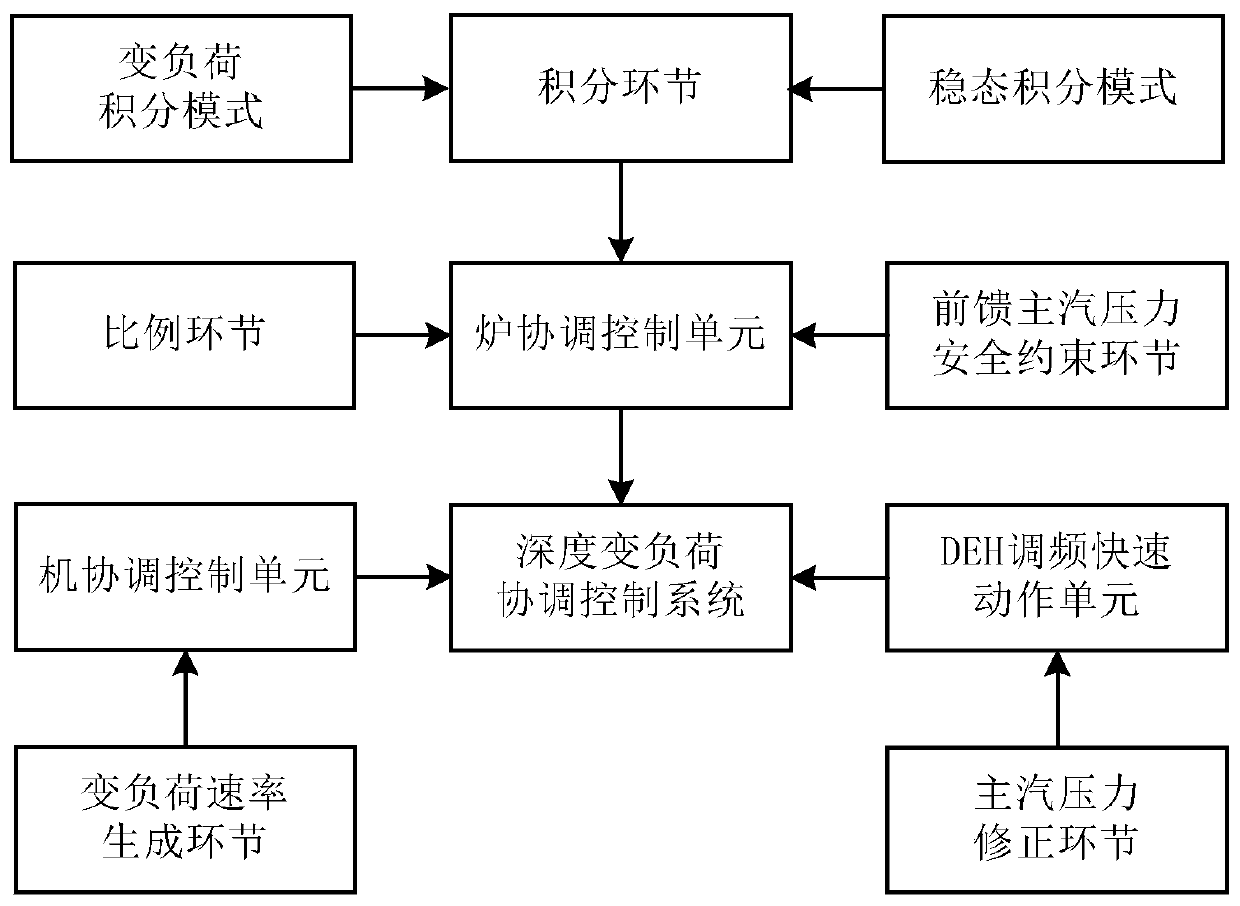

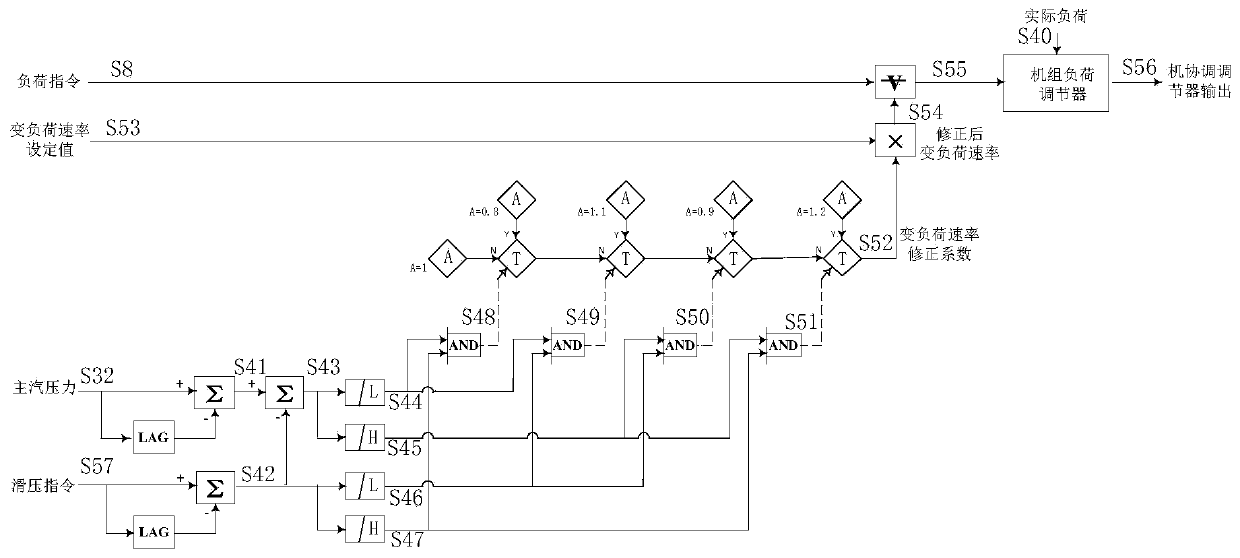

[0107] figure 1 It is the principle diagram of the coal-fired unit coordinated control method in the embodiment of the present invention, as shown in figure 1 As shown, the coal-fired unit coordinated control method provided by the present invention is based on figure 1 The furnace coordination control unit, machine coordination control unit, DEH frequency modulation fast action unit, proportional link, integral link, feed-forward main steam pressure safety constraint link, variable load integral mode, steady-state integral mode, and variable load rate generation link are used as shown. 1. In the main steam pressure correction link, the coal-fired unit coordinated control method of the present invention acts on the deep variable load coordinated control system.

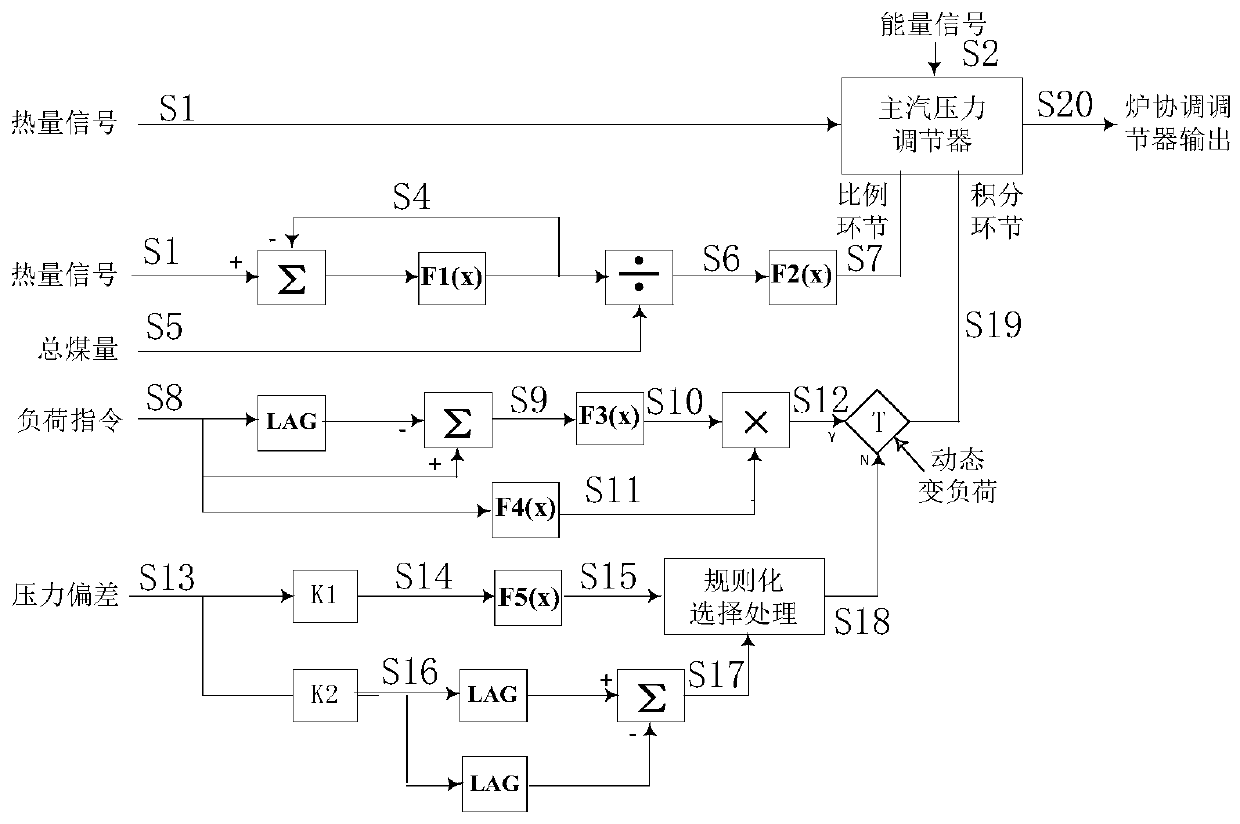

[0108]The furnace coordination control unit is adopted, and by optimizing the PI function of the main steam pressure regulator and effective control of the feed-forward amount, it not only ensures the rapidity and ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com