Flue gas desulfurization method and flue gas desulfurization device

A desulfurization device, flue gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of complex process, poor adjustment accuracy, slow response speed, etc., to meet the control objectives, fast response speed, The effect of accurate feedback measurements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

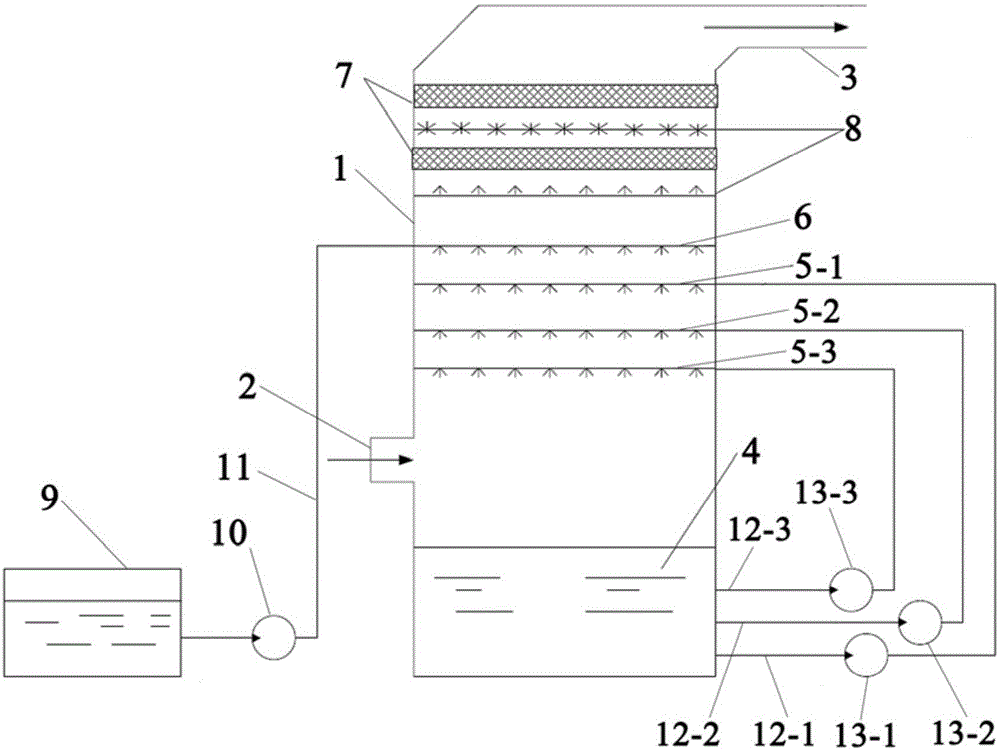

[0037] The flue gas desulfurization device of this embodiment, such as figure 1 As shown, it includes a desulfurization tower 1 and a limestone slurry pool 9 for preparing newly supplemented limestone slurry. The lower part of the desulfurization tower 1 is provided with a flue gas inlet 2 and the upper part is provided with a flue gas outlet 3. The inner flue gas inlet 2 of the desulfurization tower 1 is There is a circulating slurry pool 4 under the desulfurization tower 1, and there are three circulating slurry spray layers between the flue gas inlet 2 and the flue gas outlet 3 in the desulfurization tower 1, which are used to spray the circulating desulfurization slurry into the desulfurization tower 1, from top to bottom The first spray layer 5-1, the second spray layer 5-2 and the third spray layer 5-3; the first spray layer 5-1, the second spray layer 5-2 and the third spray layer Layer 5-3 communicates with the circulating slurry pool 4 through circulating pipelines 12...

Embodiment 2

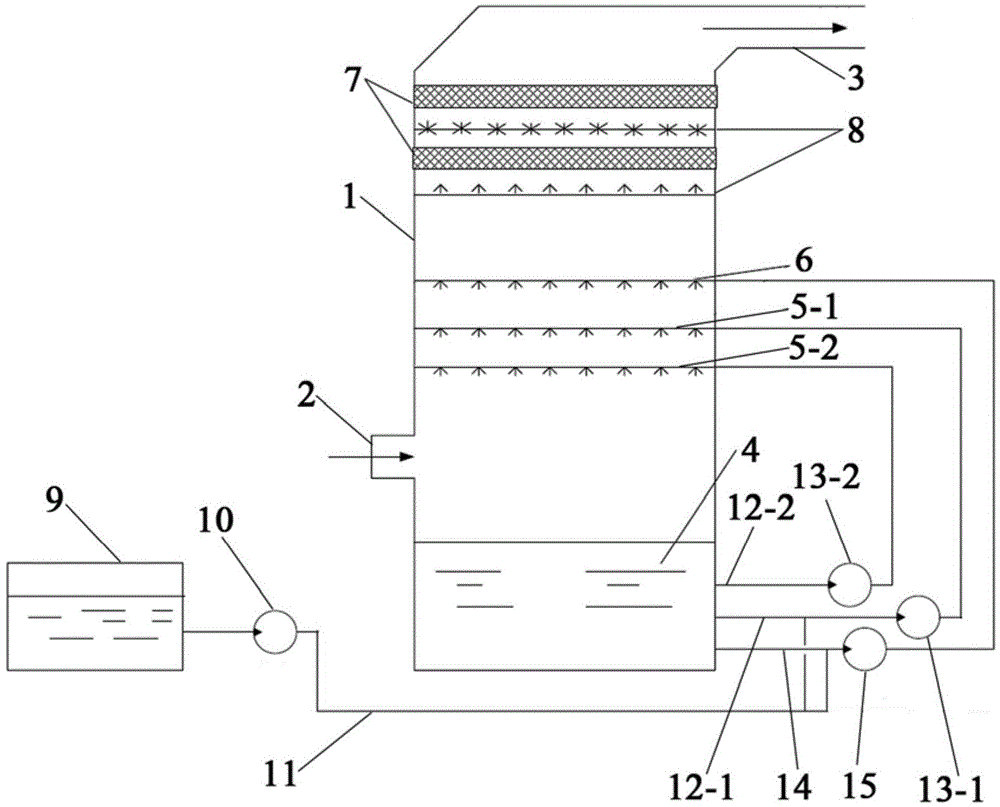

[0042] The flue gas desulfurization device of this embodiment, such as figure 2 As shown, the difference from Example 1 is that: the desulfurization tower 1 is provided with two layers of circulating slurry spray layers for spraying the circulating desulfurization slurry into the desulfurization tower 1 between the flue gas inlet 2 and the flue gas outlet 3. From top to bottom are the first spray layer 5-1 and the second spray layer 5-2;

[0043] The limestone slurry pipeline 11 is connected with a connecting pipeline 14 between the limestone slurry pump 10 and the highest spray layer 6, and the other end of the connecting pipeline 14 communicates with the circulating slurry pool 4; the limestone slurry pipeline 11 A slurry circulation pump 15 is provided between the connection with the connecting pipeline 14 and the highest spray layer, for transporting the circulating slurry in the circulating slurry pool 4 to the highest spray layer 6; A spray layer 5-1 is the second high...

Embodiment 3

[0046] The flue gas desulfurization method of this embodiment includes spraying newly supplemented limestone slurry into the desulfurization tower through the highest spray layer of the desulfurization tower; by adjusting the concentration and injection flow rate of the newly supplemented limestone slurry, controlling the flow rate of the flue gas at the outlet of the desulfurization tower Sulfur dioxide concentration.

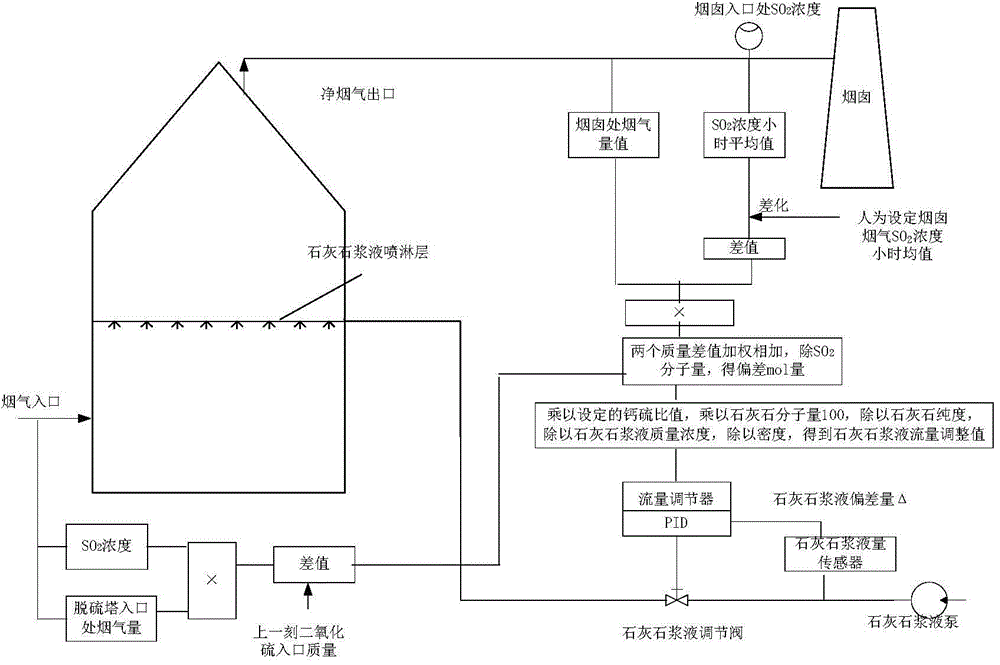

[0047] Adopt the flue gas desulfurization device of embodiment 1 to realize above-mentioned flue gas desulfurization method, the method for adjusting the concentration of the newly replenished limestone slurry and the injection flow rate specifically comprises the following steps (the principle of the control process is as follows: image 3 shown):

[0048] 1) Set the target control value of sulfur dioxide concentration in the outlet flue gas according to the externally assessed flue gas outlet sulfur dioxide concentration value (the hourly average value of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com