Copper matte air refining procedure parameter soft sensing instrument and its soft sensing method

A technology of process parameters and soft measurement, which is applied in the field of measuring instruments, can solve the problems of difficulty in ensuring the control accuracy of final quality indicators, the degradation of measurement lagging adjustment quality, and high maintenance costs, and achieve the effects of small investment, low maintenance costs, and high adjustment quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

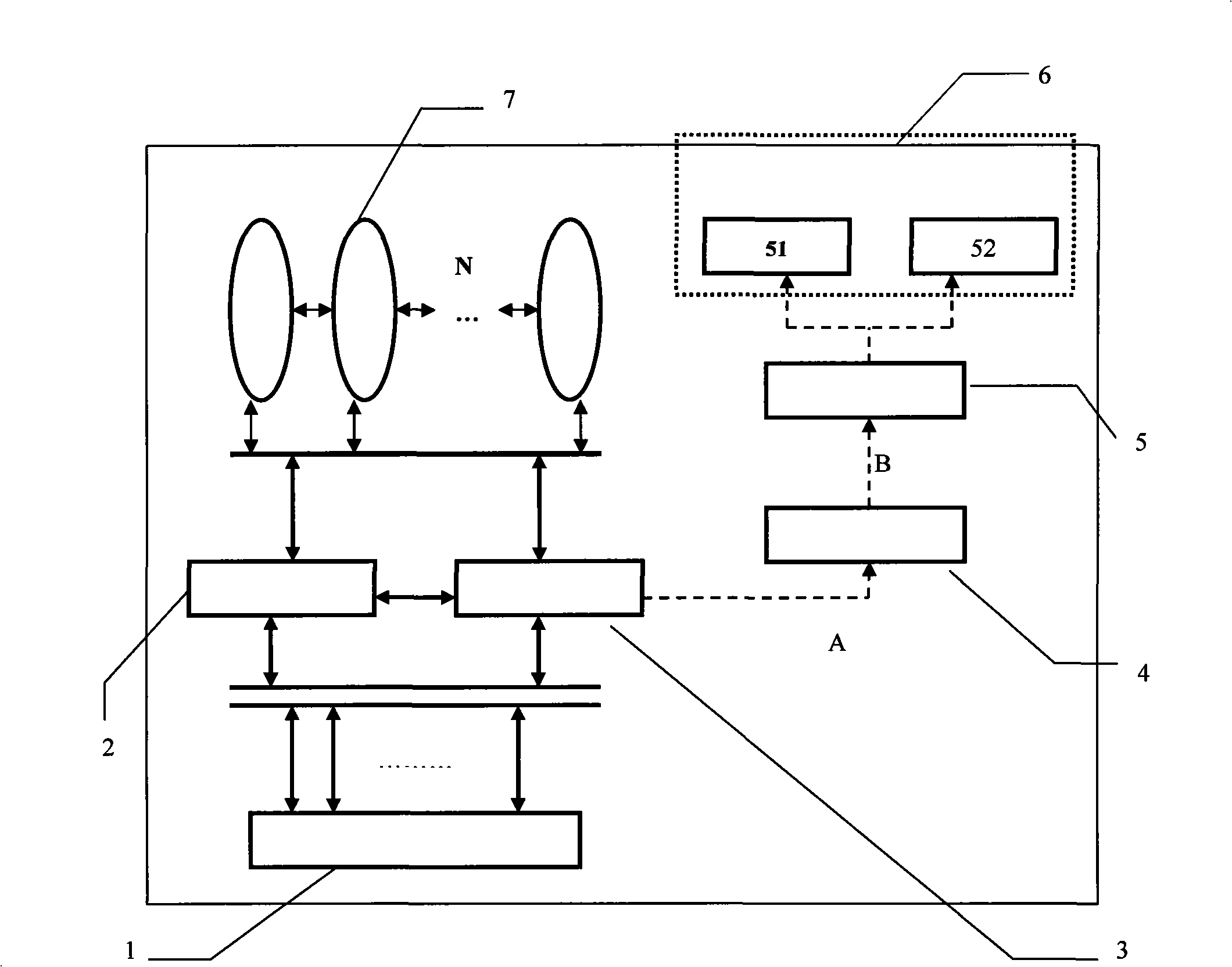

[0036] see figure 1 , through the workstation 7, the data of the field operation station and the data collected outside the sensor 1 are converted through the sensor 1 to obtain the online parameter A, which is stored on the server 2, and the online parameter A obtained through the simulator 3 is performed in the database. Real-time processing is transmitted to component a, and component b uses DDE, DAO, Jet engine and other technologies to organize and store online data, and provide the data to the soft sensor agent. exist figure 1 Among them, code 51 is IDSS model online display, 52 is online display, 4 is component a, 5 is component b, A is online parameter, B is DDE, DAO and Jet engine. DDE Server is a dedicated DDE Server for RS Works of ABB Company (the full name of DDE is Dynamic Data Exchange).

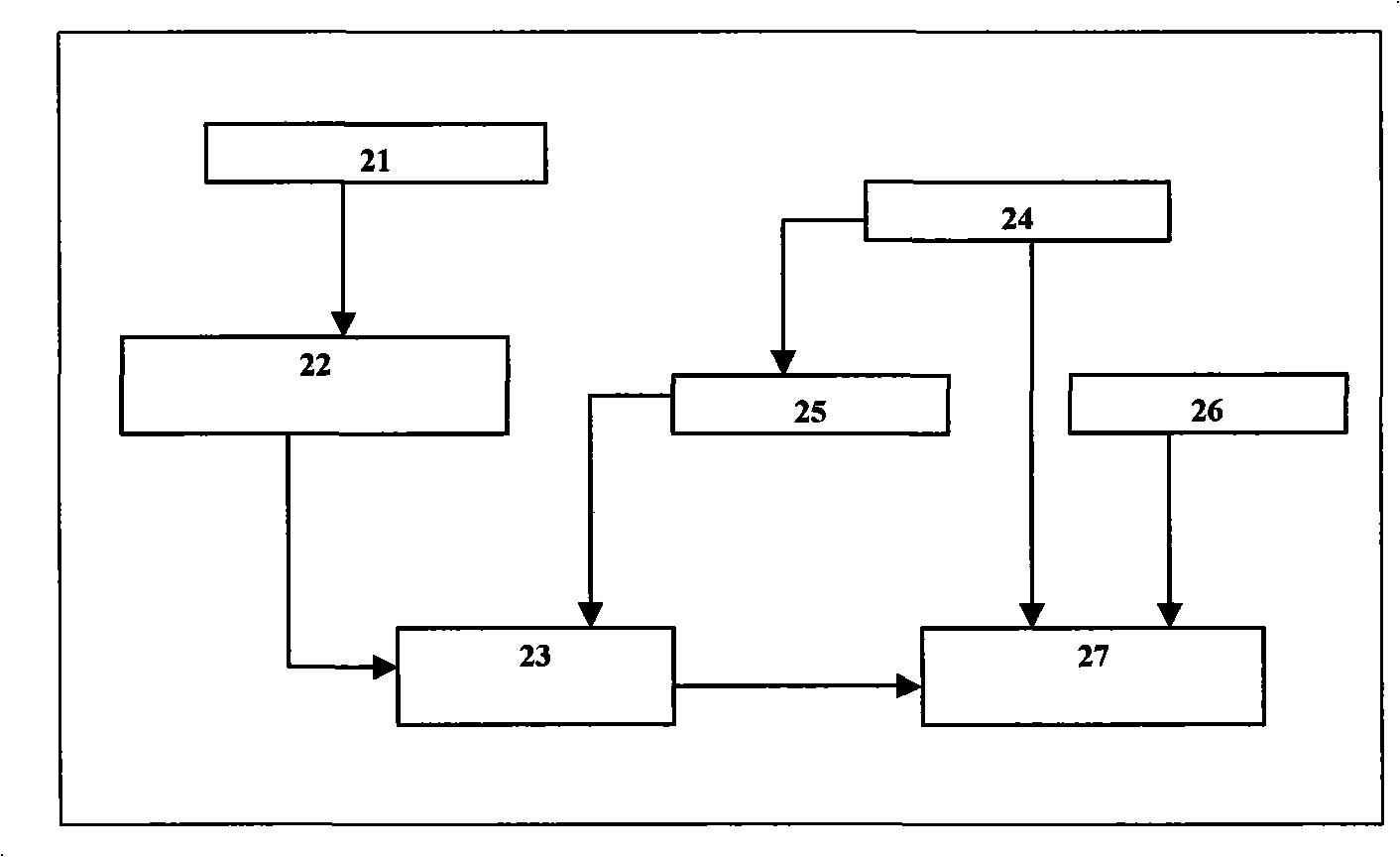

[0037] The soft sensor body includes the following seven modules (structure and function).

[0038] 1) Data online acquisition module

[0039] During the copper matte blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com