A method for utilization of waste heat using converter waste heat steam comprehensive utilization system

A waste heat steam and superheated steam technology, applied in the metallurgical industry, can solve problems such as the threat of safe operation of steam turbines, increase steam-water separators, increase system complexity, etc., to ensure safe and efficient operation, improve power generation efficiency, and reduce resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

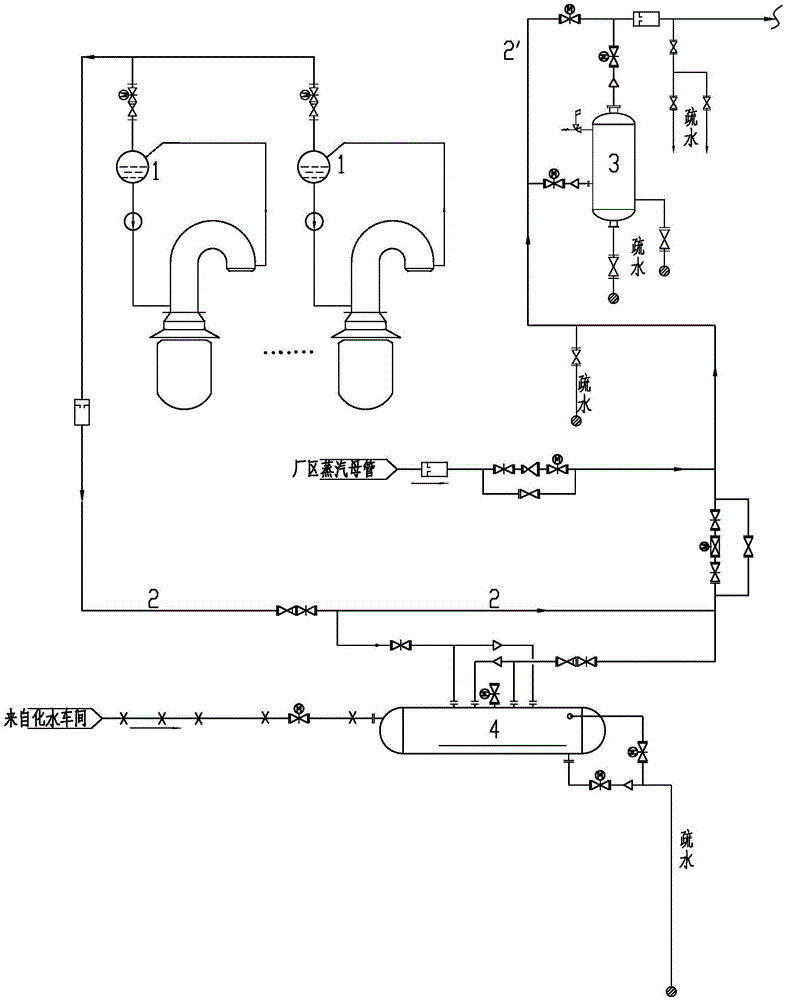

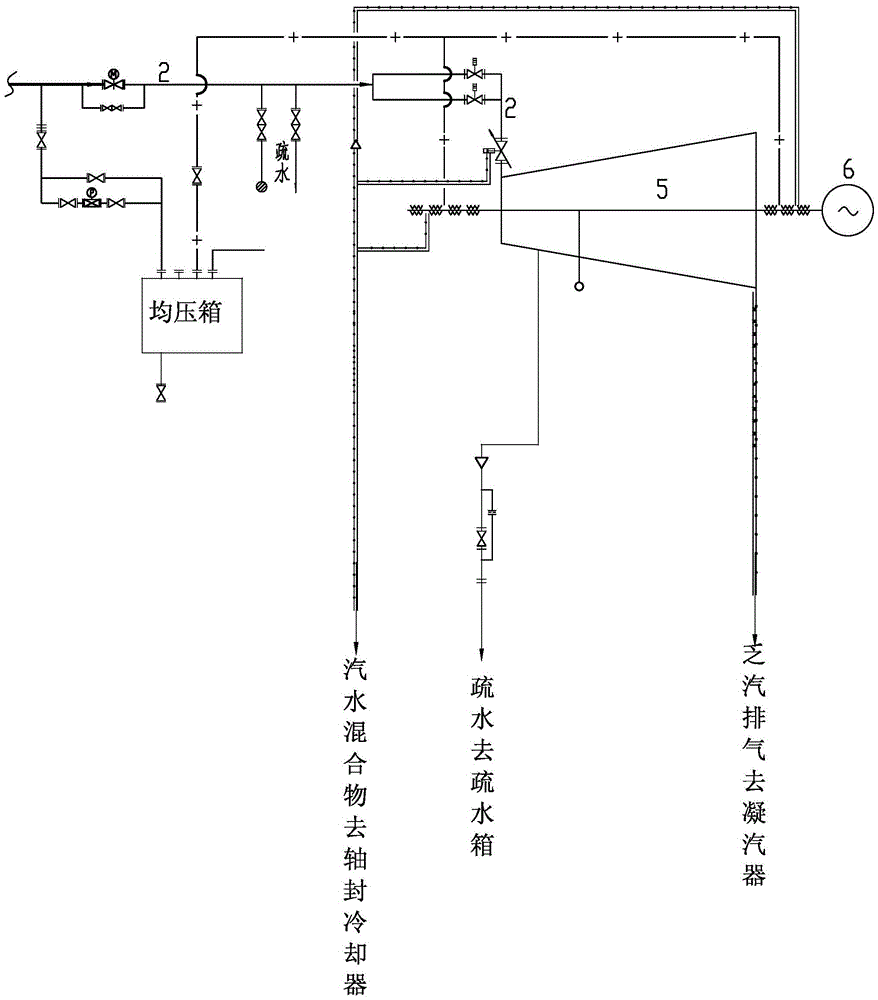

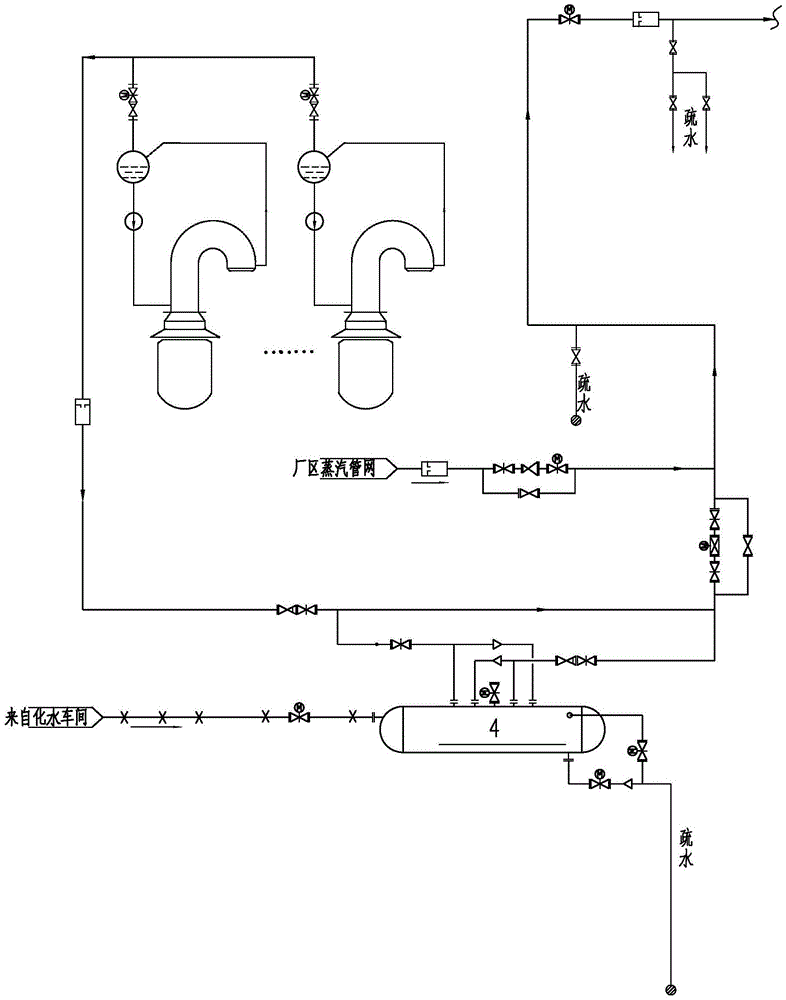

[0023] Such as figure 1 and figure 2 as shown,

[0024] The converter steam generating device 1 is a device for generating available steam in the converter steelmaking process.

[0025] A steam-water separator 3 is added before the steam pipeline 2 enters the steam turbine, and at least one set of heat accumulator 4 is added on the steam pipeline after the steam generated by the converter steam generating device 1, and at the same time, a superheated steam is introduced from the steam main pipe of the factory area and connected to the storage. In the steam pipeline 2 between the heater and the steam-water separator, electric valves, gate valves and stop valves are set in the branch pipes to control the input of superheated steam. Fully mix the superheated steam with the saturated steam generated by the heat accumulator before entering the steam-water separator to ensure that the mixed steam has a degree of superheat of more than 5 degrees, and at the same time, set a valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com