A slidable double-barrel structure pressure stabilization chamber for direct-coupled tests of solid impulse engines

A solid-impulse engine, direct-connected technology, used in engine testing, machine/structural component testing, measuring devices, etc., can solve problems affecting thrust measurement accuracy, and achieve the effect of eliminating the impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Describe the present invention below in conjunction with specific embodiment:

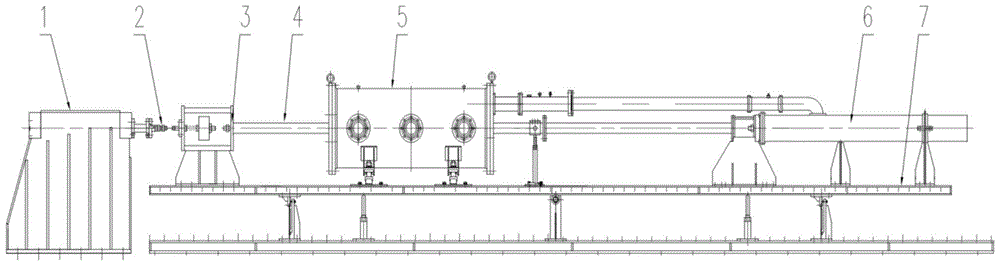

[0022] The position of this embodiment in the whole test thrust measuring device is as attached figure 1 As shown, the force frame is placed at the leftmost end of the entire thrust measurement system, and then connected with the force measurement system, pressure frame, dowel bar, pressure stabilization cabin, and solid-impact engine in sequence. During the test, the thrust generated by the solid-impact engine passes through The dowel rod is passed to the force measuring assembly for measurement. The pressure stabilization cabin is placed on the moving frame. In this way, by adjusting the position of the plenum chamber in the entire test measurement system, it is possible to prevent the engine intake pipe from being in contact with the bearing frame under the action of the airflow during the test, to ensure that the thrust axis is horizontal, thereby further reducing the impact on the thru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com